Method for arranging structure of heat exchange pipes of concrete heat storage system for solar thermal power generation

A technology of solar thermal power generation and heat exchange pipelines, which is applied in the field of solar thermal power generation heat storage systems, can solve problems such as pipeline structure layout methods that have not been reported, and achieve the effects of reducing power generation costs, increasing heat exchange rates, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

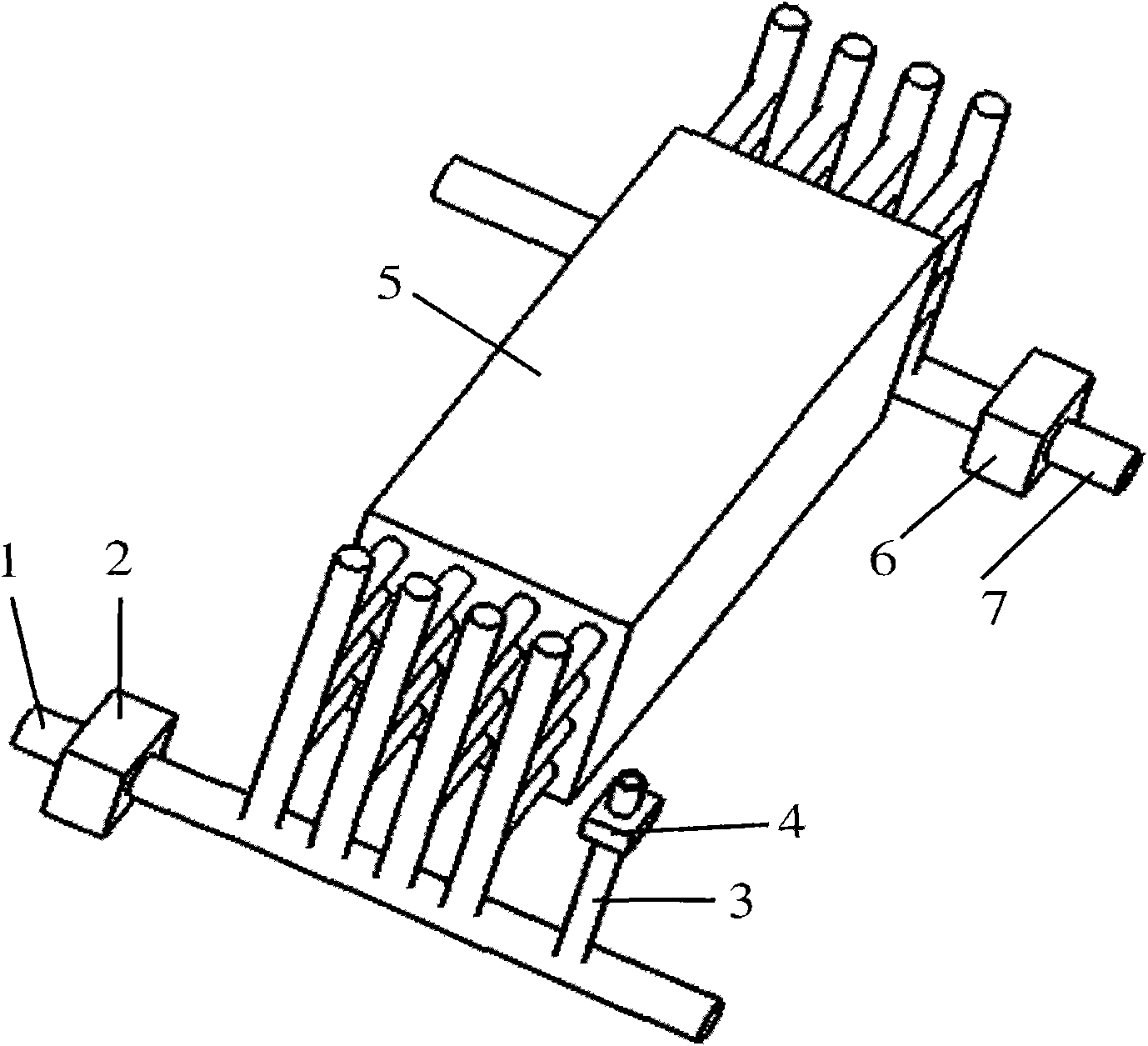

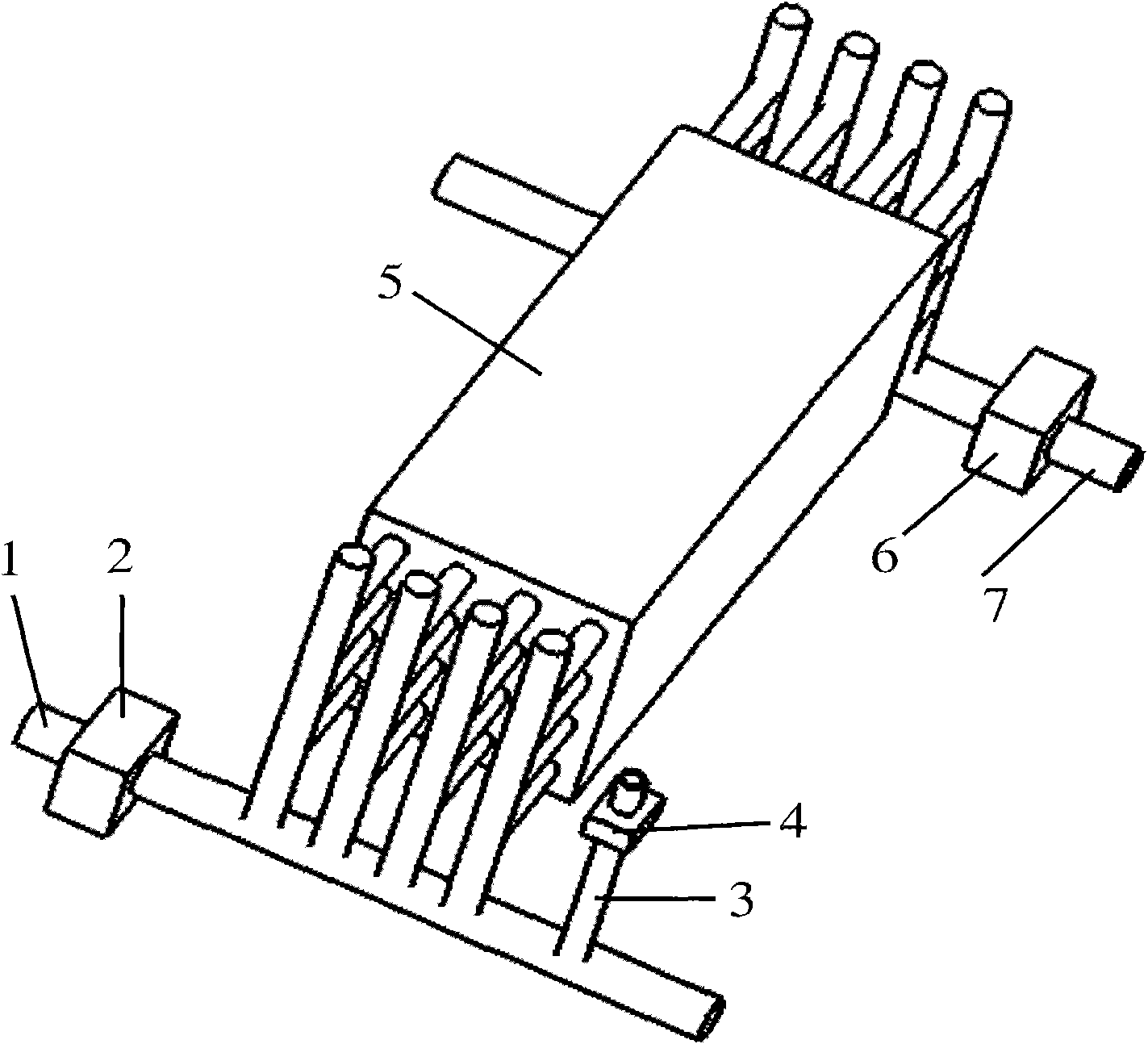

Embodiment 1

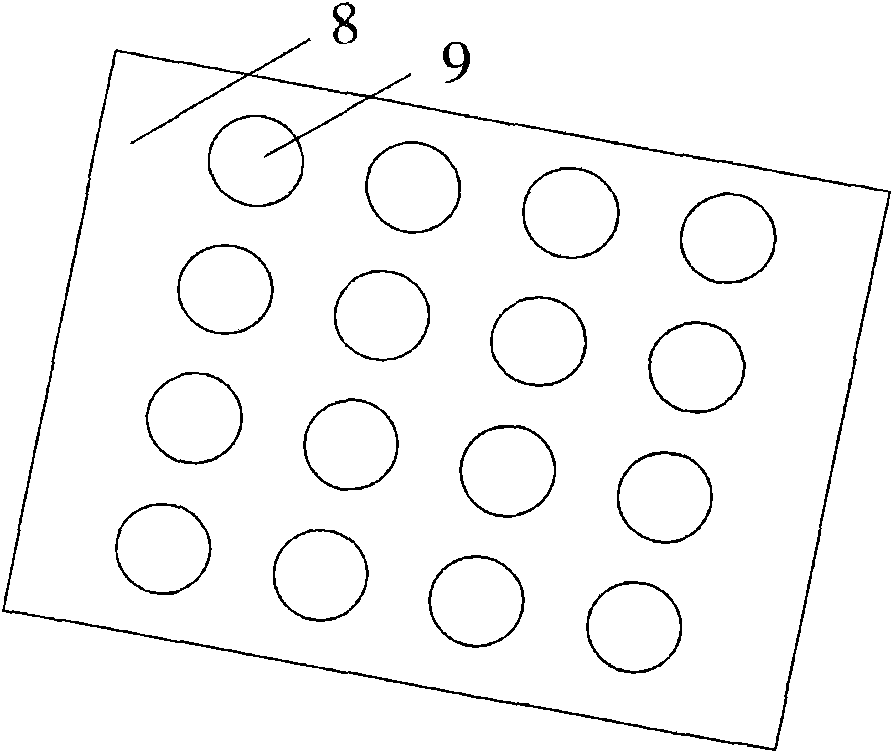

[0022] The heat exchange pipe 9 is heat-resistant stainless steel. The inlet tube is a hollow tube with an inner diameter of 10mm and an outer diameter of 16mm. The pipe directly exchanging heat with the concrete heat storage material has an inner diameter of 6mm and an outer diameter of 12mm. 100mm, each length is 70mm, the inner diameter of the outlet pipe is the same as that of the inlet pipe. The heat exchange medium is hot mineral oil with a flow rate of 1m / s. The inlet temperature is 380°C and the pressure is 0.1MPa.

[0023] The composition of heat storage material 8 is: basalt aggregate 38%, steel slag aggregate 32%, aluminate cement 8%, slag powder 15%, silicon micropowder 5%, attapulgite 2%. After the raw materials are dry-mixed evenly, add 6% water, mix evenly and place them in a steel mold with heat exchange pipes, demould after 24 hours, and maintain in water at 20-25°C for 72 hours, then dry at 100 Bake at -120°C for 24 hours to obtain a density of 2.98g / cm 3...

Embodiment 2

[0025]The heat exchange pipe 9 is heat-resistant stainless steel. The inlet tube is a hollow tube with an inner diameter of 12mm and an outer diameter of 18mm. The pipe directly exchanging heat with the concrete heat storage material has an inner diameter of 6mm and an outer diameter of 12mm. 80mm, each length is 70mm, the inner diameter of the outlet pipe is the same as that of the inlet pipe. The heat exchange medium is hot mineral oil with a flow rate of 1m / s. The inlet temperature is 450°C and the pressure is 0.2MPa.

[0026] The composition of heat storage material 8 is: basalt aggregate 35%, copper slag aggregate 35%, aluminate cement 6%, slag powder 17%, silicon micropowder 4%, attapulgite 3%. After the raw materials are dry-mixed evenly, add 5.5% water, mix evenly, place in a steel mold with a heat exchange pipe, demould after 24 hours, and maintain in water at a temperature of 20-25°C for 72 hours. Bake at 100-120°C for 24 hours to obtain a density of 2.96g / cm 3 ,...

Embodiment 3

[0028] The heat exchange pipe 9 is heat-resistant stainless steel. The inlet tube is a hollow tube with an inner diameter of 12mm and an outer diameter of 18mm. The pipe directly exchanging heat with the concrete heat storage material has an inner diameter of 6mm and an outer diameter of 12mm. 90mm, each length is 70mm, the inner diameter of the outlet pipe is the same as that of the inlet pipe. The heat exchange medium is hot steam with a flow rate of 1m / s. The inlet temperature is 350°C and the pressure is 0.2MPa.

[0029] The composition of heat storage material 8 is: basalt aggregate 38%, copper slag aggregate 32%, aluminate cement 7%, slag powder 16%, silicon micropowder 4%, attapulgite 3%. After the raw materials are dry-mixed evenly, add 5.5% water, mix evenly, place in a steel mold with a heat exchange pipe, demould after 24 hours, and maintain in water at a temperature of 20-25°C for 72 hours. Bake at 100-120°C for 24 hours to obtain a density of 2.98g / cm 3 , comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com