Glass fiber reinforced PC/PE alloy material and preparation method thereof

An alloy material and glass fiber technology, which is applied in the field of glass fiber reinforced PC/PE alloy material and its preparation, can solve the problem of reducing the practicability, toughness, strength, thermal deformation temperature deterioration and PC/PE alloy performance of PC/PE alloy material. Low and other problems, to achieve the effect of improving glass fiber distribution, improving affinity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

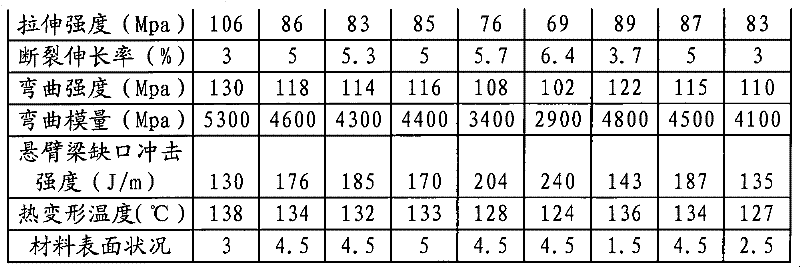

[0058] In the glass fiber reinforced PC / PE alloy material involved in the present invention, the method of adding polyethylene (PE) components to the PC material to obtain the PC / PE alloy is used to reduce the processing viscosity of the glass fiber reinforced PC material and improve the Its processing fluidity. At the same time, adding PE to PC can also improve the thick-wall impact resistance of glass fiber reinforced PC materials.

[0059] The PE used to prepare the PC / PE alloy can be high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE). Different types of PE (such as differences in melting point and fluidity) have different effects on the structure and properties of the resulting PC / PE alloy material. Relatively speaking, the viscosity of HDPE is higher, which is closer to that of PC, so it is more suitable for blending with PC to form an alloy.

[0060] The molecular chain structure, morphology, solubility parame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com