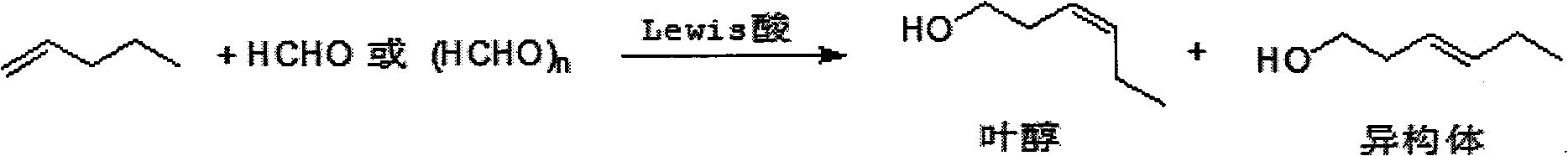

Novel method for synthesizing leaf alcohol

A technology for synthesizing leaf alcohol and a new method, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of complex process and many synthesis steps, and achieve cheap raw materials, short reaction time and convenient raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve paraformaldehyde (3g, 0.1mol) and aluminum trichloride (0.27g, 0.002mol) in dichloromethane (20ml), start magnetic stirring, at -40°C with 1-2 drops every two seconds 1-Pentene (3.5 g, 0.05 mol) was slowly added dropwise, and after the dropwise addition was completed, the temperature was raised to room temperature, and stirring was continued for 1 hour. with saturated NaHCO 3 solution (10ml) was washed, the organic phase was dried with anhydrous sodium sulfate, dichloromethane was distilled off, and the remaining crude product was distilled under reduced pressure to obtain a mixture of leaf alcohol and trans-3-hexen-1-ol. The yield 72%. Trans-3-hexen-1-ol also exists in green plants and also has the natural fragrance of grass, so this mixture can be directly used as a spice. The mixture was rectified to obtain leaf alcohol with a yield of 36%.

Embodiment 2

[0023] Dissolve paraformaldehyde (3g, 0.1mol) and tin tetrachloride (0.32g, 0.0012mol) in dichloromethane (20ml), start magnetic stirring, and drop 1-2 drops every two seconds at -20°C 1-Pentene (3.5 g, 0.05 mol) was slowly added dropwise, and after the dropwise addition was completed, the temperature was raised to room temperature, and stirring was continued for 4 hours. with saturated NaHCO 3 solution (10ml) was washed, the organic phase was dried with anhydrous sodium sulfate, dichloromethane was distilled off, and the remaining crude product was distilled under reduced pressure to obtain a mixture of leaf alcohol and trans-3-hexen-1-ol. The yield 85%. The mixture was rectified to obtain leaf alcohol with a yield of 43%.

Embodiment 3

[0025] Dissolve paraformaldehyde (30g, 1mol) and tin tetrachloride (3.2g, 0.012mol) in carbon tetrachloride (200ml), start magnetic stirring, and drop 1-2 drops every two seconds at -20°C 1-Pentene (42 g, 0.6 mol) was added dropwise at a high speed, and after the dropwise addition was completed, the temperature was raised to room temperature, and stirring was continued for 4 hours. with saturated NaHCO 3 solution (100ml), the organic phase was dried with anhydrous sodium sulfate, dichloromethane was distilled off, and the remaining crude product was distilled under reduced pressure to obtain a mixture of leaf alcohol and trans-3-hexene-1-ol. The yield 82%. The mixture was rectified to obtain leaf alcohol with a yield of 41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com