A preparation method of a molecular chain regulator for improving the mechanical properties of polystyrene waste plastics

A technology of chain regulator and polystyrene, which is applied in the field of preparation of molecular chain regulator, can solve the problems of high modifier price, rigidity, tensile strength and processing performance reduction, and achieve economical and applicable production process and improve preservation The effect of improving time and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] 1) Add 30g of α-cyclodextrin to 1000g of absolute ethanol solvent, then put it into an ultrasonic environment (500W power, 20KHz frequency) to dissolve for 30min, then gradually add 10g dibenzoyl peroxide, 20g dibenzoyl peroxide Dicumylbenzene, 10g of azobisisobutyronitrile, 10g of 2,3 dicyano-2,3 diethyl diphenylsuccinate, and continue ultrasonication for 30 minutes;

[0009] 2) The solution prepared above was distilled under reduced pressure, dried under vacuum at 8°C after distillation, and then ground by a ball mill for 40 minutes at 8°C to obtain a cyclodextrin-coated initiator powder;

[0010] 3) Dissolve 50 g of the powder obtained by the above distillation, 1 g of 2,5-di-tert-butylhydroquinone and 50 g of dispersant in 1 kg of styrene monomer, stir and dissolve fully to obtain a molecular chain regulator . Add 3% of the molecular chain regulator in the granulation process of polystyrene waste plastics, and the described dispersant is a compound of 1:1 (weight r...

Embodiment 2

[0012] 1) Add 80g of β-cyclodextrin to 1000g of absolute ethanol solvent, then put it into an ultrasonic environment (power 800W, frequency 40KHz) to dissolve for 50min, then gradually add 20g of dibenzoyl peroxide, 20g of azo Diisobutyronitrile, 10g azobisisobutyronitrile, 5g 2,3-dicyano-2,3-diphenylsuccinate diethyl, continue ultrasonication for 50min;

[0013] 2) The solution prepared above was distilled under reduced pressure, dried in vacuum at 8°C after distillation, and then ground by a ball mill for 50 minutes at 8°C to obtain a cyclodextrin-coated initiator powder;

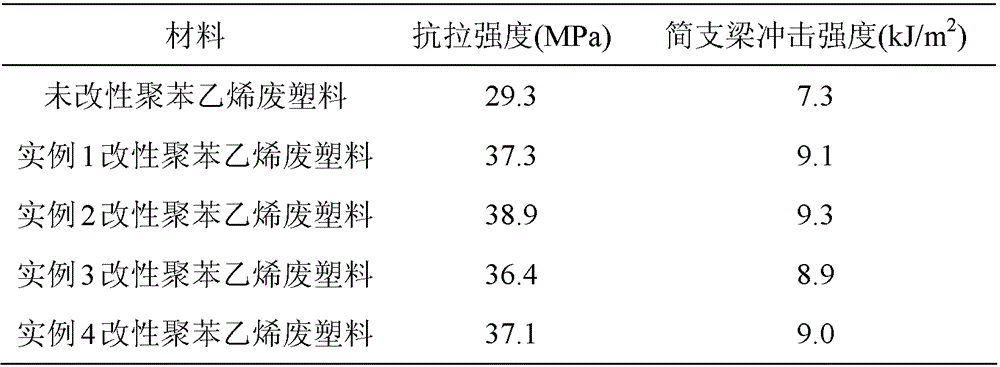

[0014] 3) Dissolve 60 g of the powder obtained by the above distillation, 2 g of 2,5-di-tert-butylhydroquinone and 60 g of dispersant in 1 kg of styrene monomer, stir and dissolve to obtain a molecular chain regulator , The dispersant is a 1:1 (weight ratio) compound of sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether. The mechanical properties of the 3% molecular chain regulator adde...

Embodiment 3

[0017] 1) Add 110g of γ-cyclodextrin to 1000g of absolute ethanol solvent, then put it into an ultrasonic environment (power 1100W, frequency 60KHz) to dissolve for 60min, then gradually add 20g of dibenzoyl peroxide, 20g of peroxide Dicumyl, 20g azobisisobutyronitrile, continue ultrasonication for 50min;

[0018] 2) The solution prepared above was distilled under reduced pressure, dried in vacuum at 8°C after distillation, and then ground by a ball mill for 60 minutes at 8°C to obtain a cyclodextrin-coated initiator powder;

[0019] 3) 80 g of the powder obtained by the above distillation, 3 g of 2,5-di-tert-butyl hydroquinone and 80 g of dispersant are dissolved in 1 kg of styrene monomer, fully stirred and dissolved to obtain a molecular chain regulator, The dispersant is a 1:1 (weight ratio) compound of sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether. . Add 3% of the molecular chain regulator in the granulation process of polystyrene waste plastics, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com