Duplex overflow weir capable of promoting vapor-liquid separation

A technology of vapor-liquid separation and overflow weir, which is applied in distillation separation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the inlet resistance of the downcomer, high liquid flow intensity, pulse-like fluctuations, etc., and achieves improved operation. The effect of stability, improving vapor-liquid contact and reducing overflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

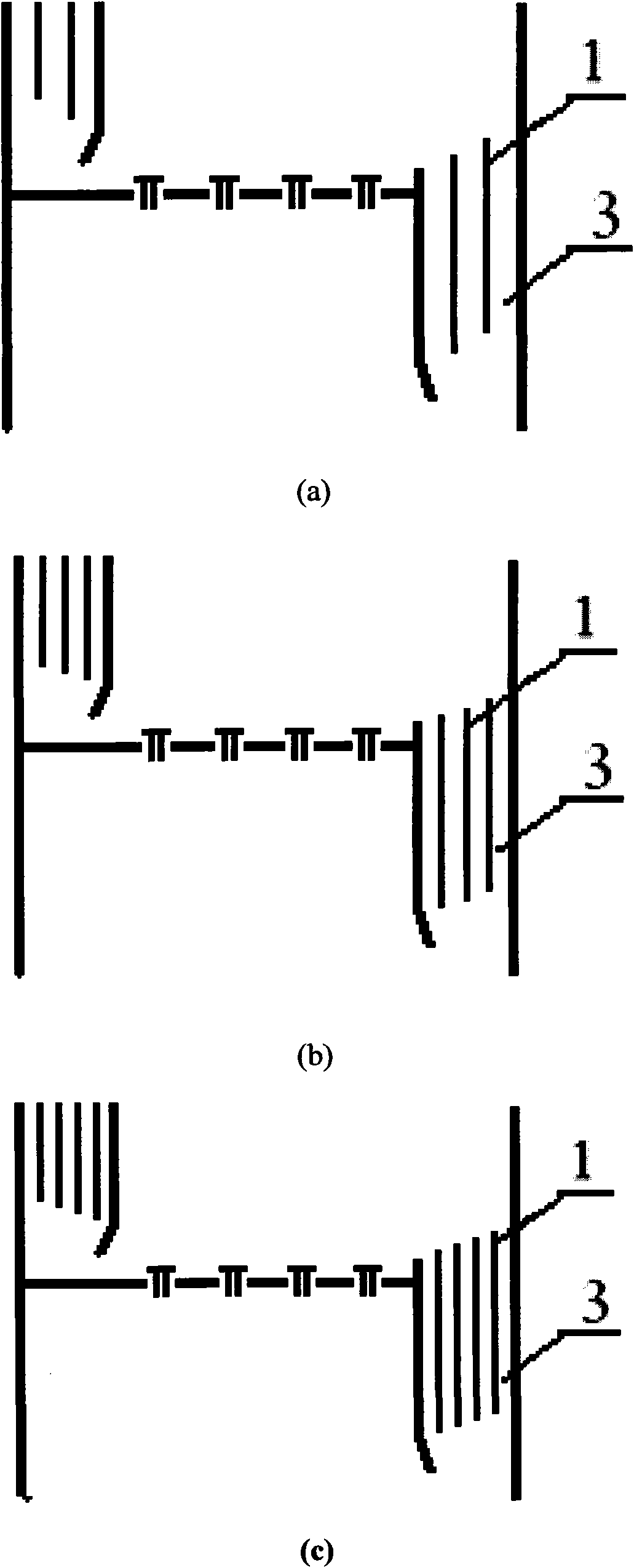

[0057] as attached image 3 As shown, the present invention relates to a compound overflow weir for arcuate downcomers in plate towers, comprising two or more layers of weir plates 1, openings 2 and vapor-liquid channels 3 on the weir plates, each A layer of weir plate 1 is arranged between the outlet of the tray and the tower wall, and the space between the two layers of weir plates 1 constitutes a vapor-liquid channel 3, and no weir plate (1) is provided at the connection between the outlet of the tray and the downcomer plate. The top of the downcomer is flush with the tray.

[0058] The upper edge of each layer of weir plate 1 is arranged along the direction from the tray outlet to the tower wall, according to the gradient from low to high. The lower edge of each layer of weir plate 1 can be arranged in the same way as the upper edge along the direction from the outlet of the tray to the tower wall, or it can also be different. Along the liquid flow direction, that is, al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com