Method for preparing elastic chocolate sauce

A chocolate and sauce technology, applied in cocoa, frozen desserts, food science, etc., can solve the problems of no bite, large amount of colloid, high viscosity, etc., to achieve the effect of full flavor, rich taste, and improved color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

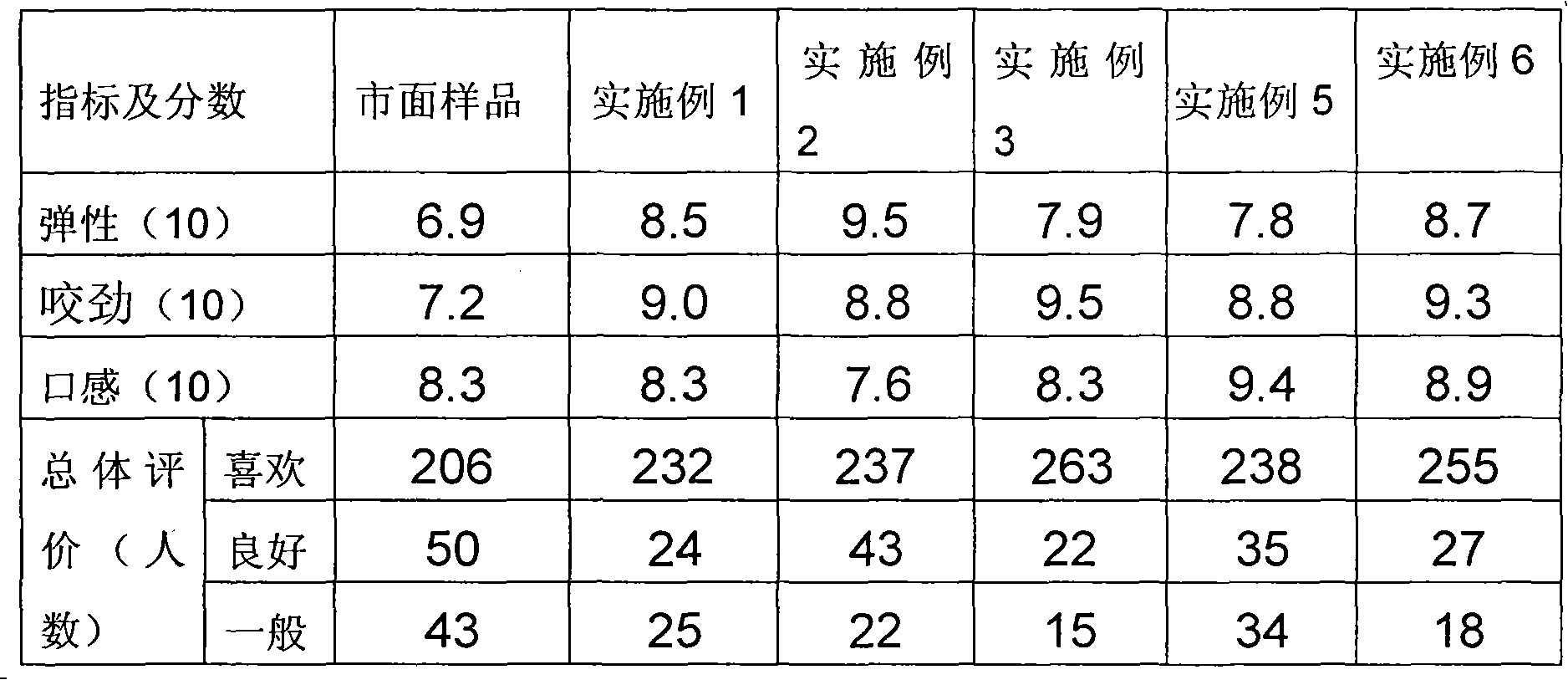

Examples

Embodiment 1

[0015] Produce 1000 kilograms of chocolate flavor sauces that are used for frozen drinks, the formula of the raw material that adopts is by weight percentage is:

[0016] Chocolate 40%, Palm Oil: 20%, High Fructose Syrup: 15%, Malt Syrup: 25%.

[0017] The chocolate ingredients are:

[0018] Caster sugar: 35%, coconut oil: 32.2%, cocoa butter: 10%, whole milk powder: 12%, cocoa powder: 10%, lecithin 0.8%

[0019] The preparation method is:

[0020] 1) First, white sugar, coconut oil, cocoa butter, whole milk powder, cocoa powder and lecithin are ground into chocolate through a fine grinder, and the fineness of the ground chocolate is controlled below 35 μm;

[0021] 2) The ground chocolate is used as ingredients, and fructose syrup, malt syrup and palm oil are further supplemented;

[0022] 3) Heating the mixed solution to 60°C, and after the mixed solution turns brown in color and has a sudden change in state, continue heating to 75°C and keep it warm for 15 minutes;

[0...

Embodiment 2

[0028] Produce 1000 kilograms of chocolate flavor sauces that are used for frozen drinks, the formula of the raw material that adopts is by weight percentage is:

[0029] Chocolate 30%, cocoa butter: 15%, fructose syrup: 15%, malt syrup: 30%, chocolate essence 0.1%, and the rest is water.

[0030] The chocolate ingredients are:

[0031] White sugar: 35%, salad oil: 22.2%, cocoa butter substitute: 10%, cocoa butter: 10%, whole milk powder: 12%, cocoa powder: 10%, lecithin 0.8%

[0032] The preparation method is:

[0033] 1) First, white sugar, salad oil, cocoa butter substitute, cocoa butter, whole milk powder, cocoa powder and lecithin are ground into chocolate through a fine grinder, and the fineness of the ground chocolate is controlled below 35 μm;

[0034] 2) The ground chocolate is used as ingredients, and fructose syrup, malt syrup, cocoa butter, chocolate essence and water are further supplemented;

[0035] 3) Heat the mixed solution to 55°C, and continue heating to ...

Embodiment 3

[0041] Produce 1000 kilograms of chocolate flavor sauces that are used for frozen drinks, the formula of the raw material that adopts is by weight percentage is:

[0042] Chocolate 50%, Palm Oil: 15%, High Fructose Syrup: 15%, Malt Syrup: 20%.

[0043] Wherein chocolate still uses the chocolate prescription among the embodiment 1.

[0044] The preparation method is:

[0045] 1) First, white sugar, coconut oil, cocoa butter, whole milk powder, cocoa powder and lecithin are ground into chocolate through a fine grinder, and the fineness of the ground chocolate is controlled below 35 μm;

[0046] 2) The ground chocolate is used as ingredients, and palm oil, fructose syrup, and malt syrup are further supplemented;

[0047] 3) Heat the mixed solution to 65°C, and after the mixed solution turns brown in color and changes state, continue heating to 72°C and keep it warm for 12 minutes;

[0048] 4) add water and set the volume to 1000 kg, so that the water content of the obtained ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com