Processing method for non-fried vacuum-frozen puffed winter jujubes

A technology for vacuum freezing and puffing winter jujube, which is applied in the fields of food preservation, fruit and vegetable preservation, food science, etc., can solve the problems affecting the sensory and quality of puffed and puffed winter jujube, affecting product sensory evaluation, and skin folds of winter jujube, and achieving a complete and good appearance. Crispy, jujube full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

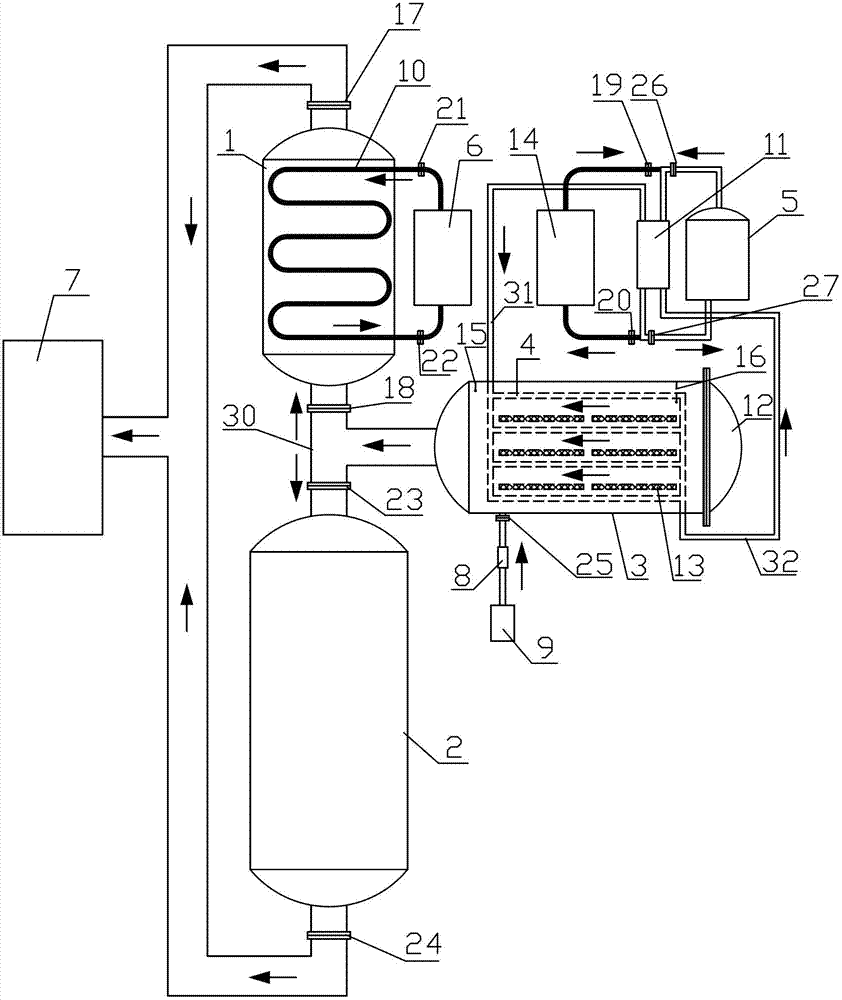

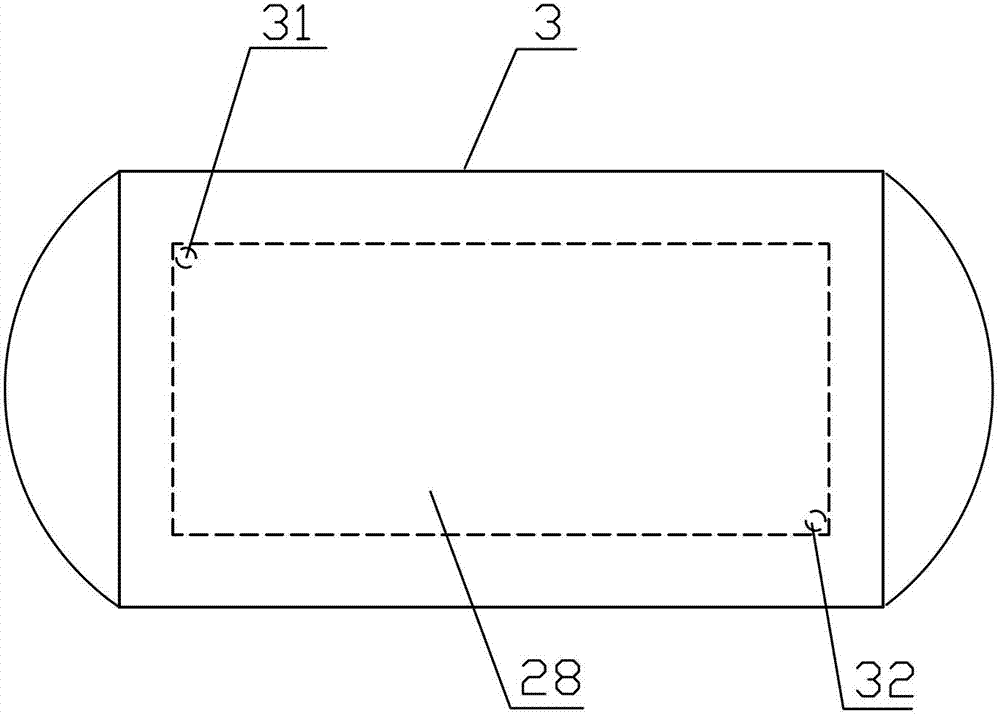

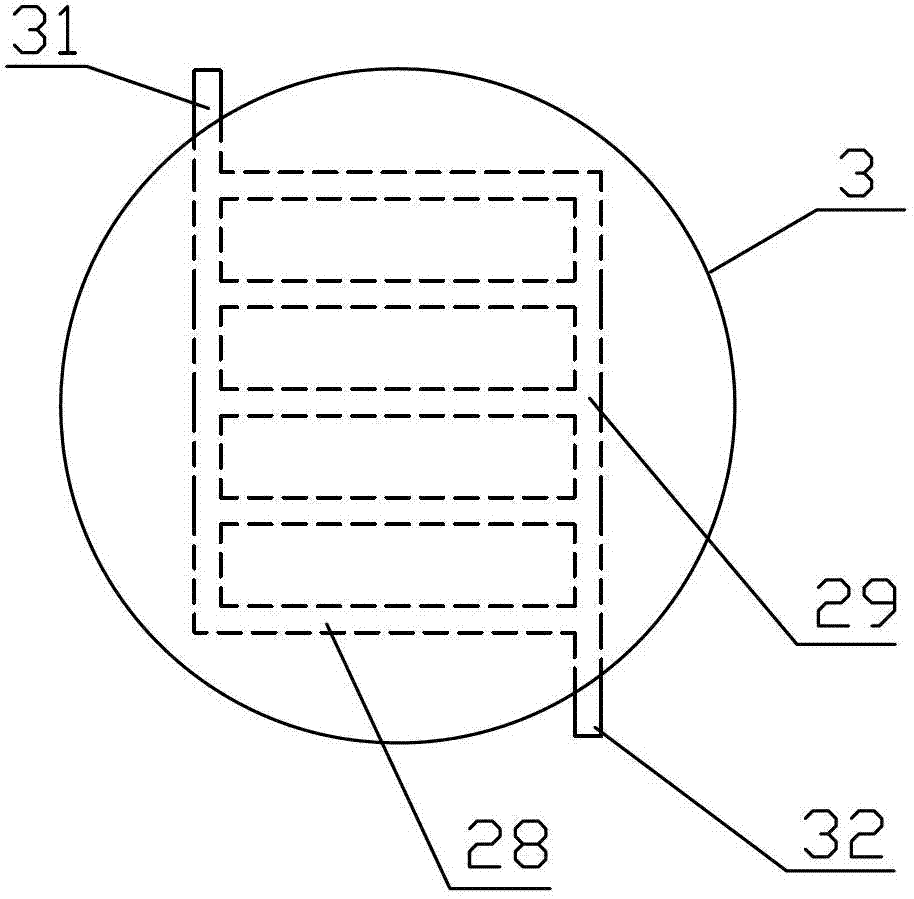

[0017] Refer to the attached figure 1 , attached figure 2 And attached image 3 The processing method of a kind of non-fried vacuum frozen puffed winter jujube of the present invention is described in detail below.

[0018] A processing method of non-fried vacuum frozen puffed winter jujube according to the present invention, its structure (1) raw material pretreatment: the fresh winter jujube is subjected to inspection, cleaning, core penetration, and Vc color protection treatment;

[0019] (2) Non-fried vacuum freeze puffing drying by non-frying vacuum freeze puffing dryer: the operation process is: after the pretreated raw materials are quick-frozen, spread them into a single layer, evenly distribute them on the material tray 13, put them into puffed The tank 3 is placed on the heating plate 4, the door 12 of the expansion tank is closed, and the expansion tank 3 is closed;

[0020]Turn on the vacuum unit 7 and the refrigeration unit 6, open the first pneumatic valve 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com