Parallel-series electrode multigap energy-saving environmental-friendly spark plug

An energy-saving and environment-friendly spark plug technology, which is applied to spark plugs, electrical components, circuits, etc., can solve the problems of non-adjustable electrode gaps that affect the ignition reliability of spark plugs, increase the difficulty of spark plug electrode discharge, and increase the effective ignition gap. The effect of shortening the time, improving the stability, and reducing the variation range of the combustion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

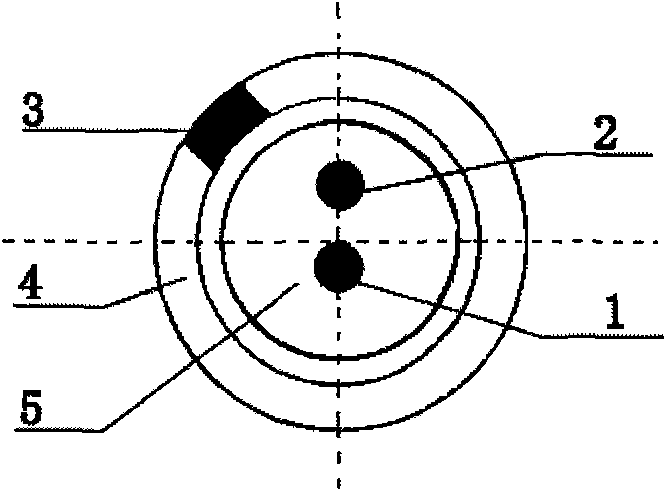

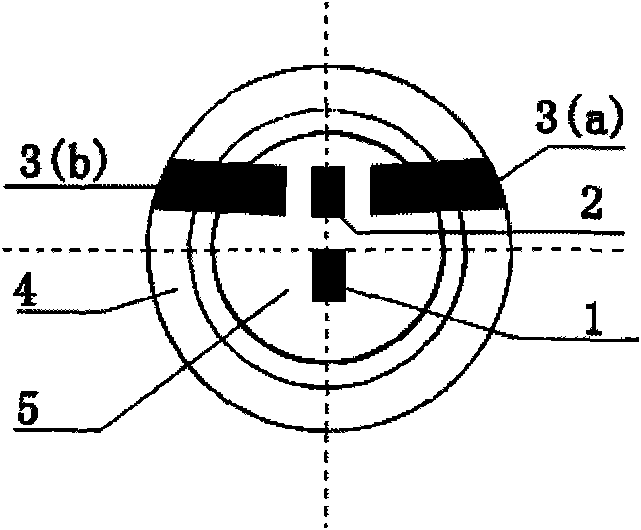

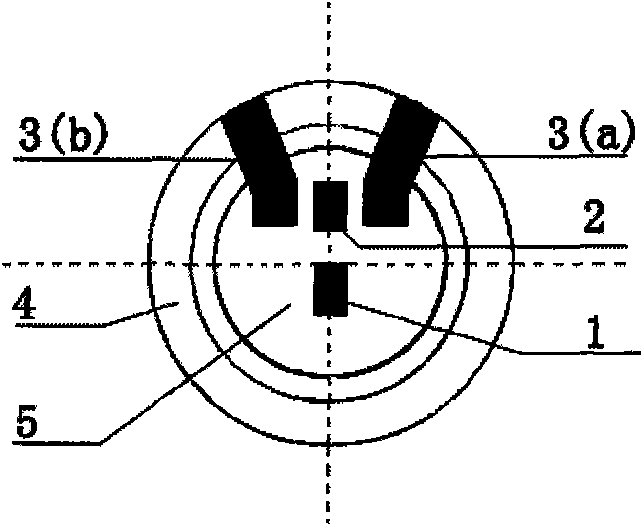

[0021] refer to figure 2 and 3 , weld the curved or hook-shaped side electrodes 3(a), 3(b) on the shell 4, and the spacing is appropriate; between the center of the ceramic core 5 and its edge, a central electrode 1 and a bridging center electrode are respectively arranged. The electrodes 2 and their upper ends are all exposed on the porcelain surface, and are arranged in a "Y" shape with the side electrodes 3(a) and 3(b), and the bridging central electrode 2 is sandwiched between the side electrodes 3(a) and 3(b) , the specific size of the gaps and the specifications of the electrodes, the location settings and other details need to be determined by system tests.

[0022] In the first embodiment, refer to figure 2 and 3 , because the upper end of the center electrode 1 and the bridging center electrode 2 are exposed to the porcelain surface in a square flat shape, the discharge method changes from a cylindrical surface R arc discharge to a square flat shape with angular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com