Metallurgical molten slag dry-type processing device and processing method thereof

A dry processing and slag technology, applied in the direction of recycling technology, process efficiency improvement, etc., can solve the problems of large equipment footprint and low heat recovery efficiency, meet the requirements of reducing the footprint and improve the feasibility , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Those skilled in the art can better understand the further disclosure, purpose, advantages and aspects of the present application with reference to the preferred embodiments of the present invention in conjunction with the accompanying drawings, and these provided drawings and embodiments are only for the purpose of illustration , rather than limiting the scope of protection of the invention.

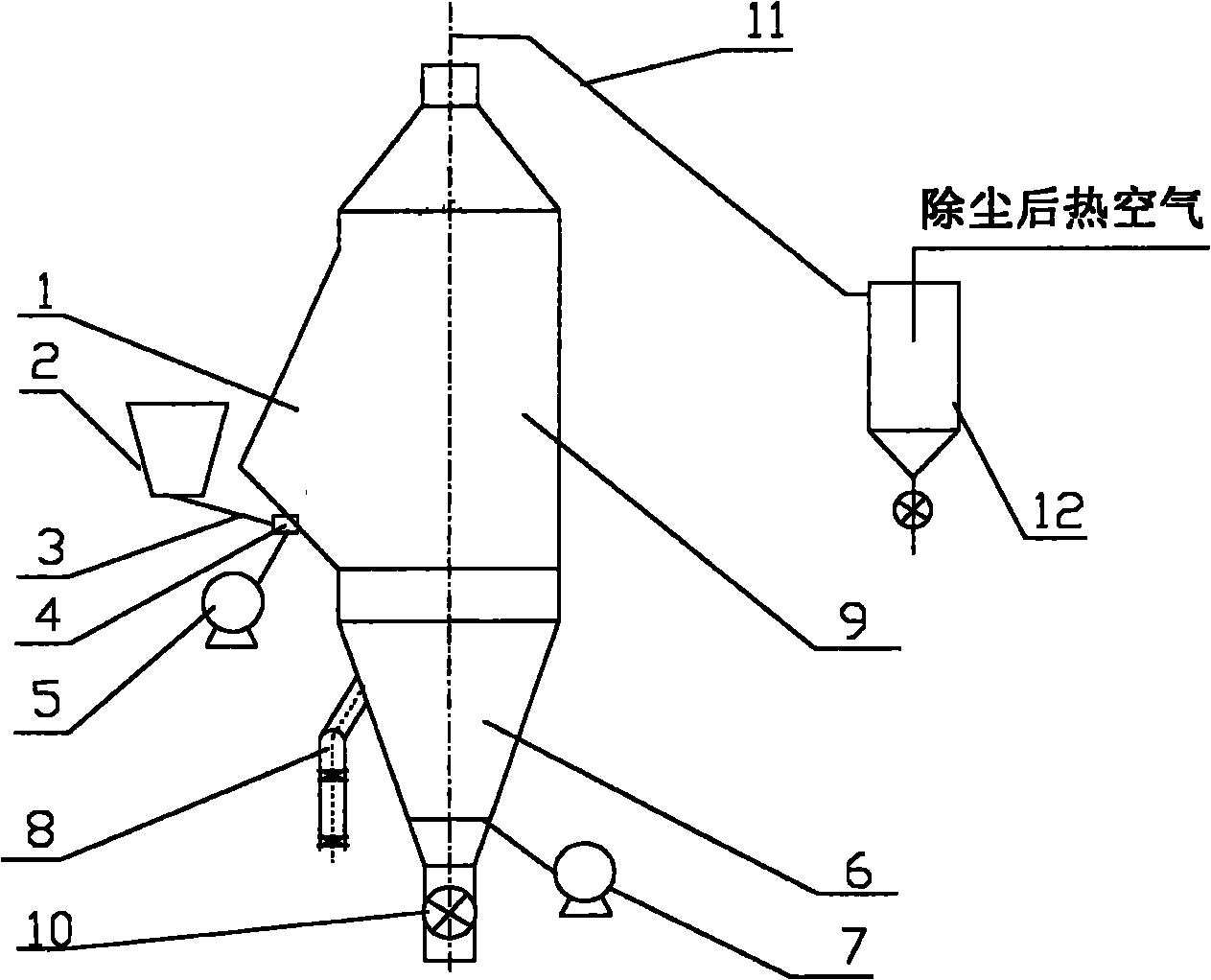

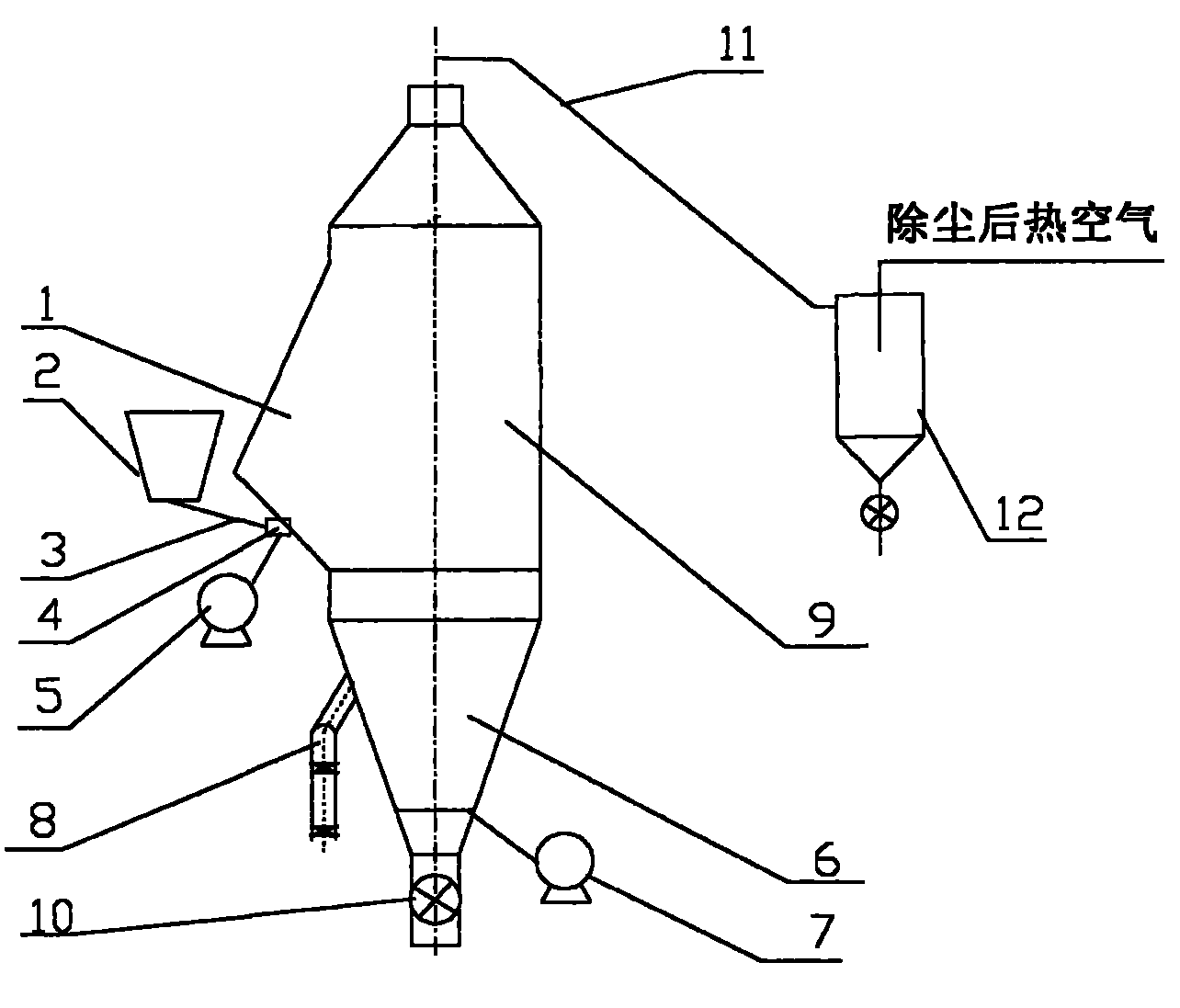

[0025] Exemplary embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The same reference numerals in the figures denote the same parts. Such as figure 1As shown, the present invention proposes a dry processing device for metallurgical slag, including: a treatment furnace 1 for granulating and cooling high-temperature slag and obtaining high-temperature air; and for introducing high-temperature slag into the treatment furnace 1 The slag introduction unit 2,3. Wherein the processing furnace 1 comprises: a body of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com