Ether energy and preparation method and application thereof

An energy and ether technology, applied in the field of ether energy and its preparation, can solve the problems of long production cycle and high energy consumption, and achieve the effect of convenient separation, simple reaction device and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of sucrose ether liquid energy from sucrose

[0045] (1) Dissolve 50 g of sucrose (analytically pure, the molar number of hydroxyl groups is 1.169 mol) in 50 mL of water.

[0046] (2) Dissolve 47g (1.169mol) of sodium hydroxide in 50mL of water and cool in an ice bath.

[0047] (3) Pour the solutions obtained in steps (1) and (2) into a high-temperature and high-pressure reactor, add 150 mL of monochloroethane (2.14 mol), and react with magnetic stirring at 120° C. for 12 h.

[0048] (4) After the reaction was completed, the upper layer of the reaction solution was separated, and the volume fraction was added to 50% sulfuric acid solution until the pH value was neutral, and the sodium sulfate was left to stand to precipitate, and then centrifuged at 3000r / min for 10min to obtain the supernatant.

[0049] (5) Purification of samples:

[0050] The following two methods were used for purification:

[0051] ①Add 50mL of chloroform to the supernatant obtained ...

Embodiment 2

[0057] Preparation of sucrose mannitol ether liquid energy from mannitol

[0058] (1) Take 50g of mannitol (the molar number of hydroxyl groups is 1.64mol), add 50mL of water to dissolve in the reaction kettle, and then add 60g of silver oxide.

[0059] (2) Add 115 mL of monochloroethane (1.64 mol), and react with magnetic stirring at 110° C. for 2 h.

[0060] (3) After the reaction, the supernatant of the reaction solution was separated, and the samples were purified by the following methods:

[0061] ① The supernatant obtained in step (3) was washed with water until the pH value was neutral, and the water was evaporated to dryness under vacuum at 60-80° C. to obtain an oily product.

[0062] ② The supernatant obtained in step (3) is washed with water until the pH value is neutral, and dried directly or with a dehydrating agent at 100-105° C. to obtain an oily product.

[0063] After testing, the products obtained by purification methods ① and ② are the same, and the specif...

Embodiment 3

[0067] Preparation of Glycerol Ether Liquid Energy from Glycerol

[0068] (1) Take 35 mL of glycerol (analytical pure) (the number of moles of hydroxyl groups is 1.19 mol).

[0069] (2) Dissolve 120g of potassium hydroxide in 200mL of water and cool in an ice bath.

[0070] (3) Pour the solutions obtained in steps (1) and (2) into a high-temperature and high-pressure reactor, add 250 mL of monochloroethane (3.57 mol), and react with medium-speed magnetic stirring at 120 ° C for 1 h.

[0071] (4) After the reaction, separate the supernatant of the reaction solution, evaporate the water to dryness at a vacuum of 0.1 MPa and a temperature of 40°C; raise the temperature to 90-120°C to distill the product.

[0072] After testing, the products obtained by purification methods ① and ② are the same, and the specific test results are as follows:

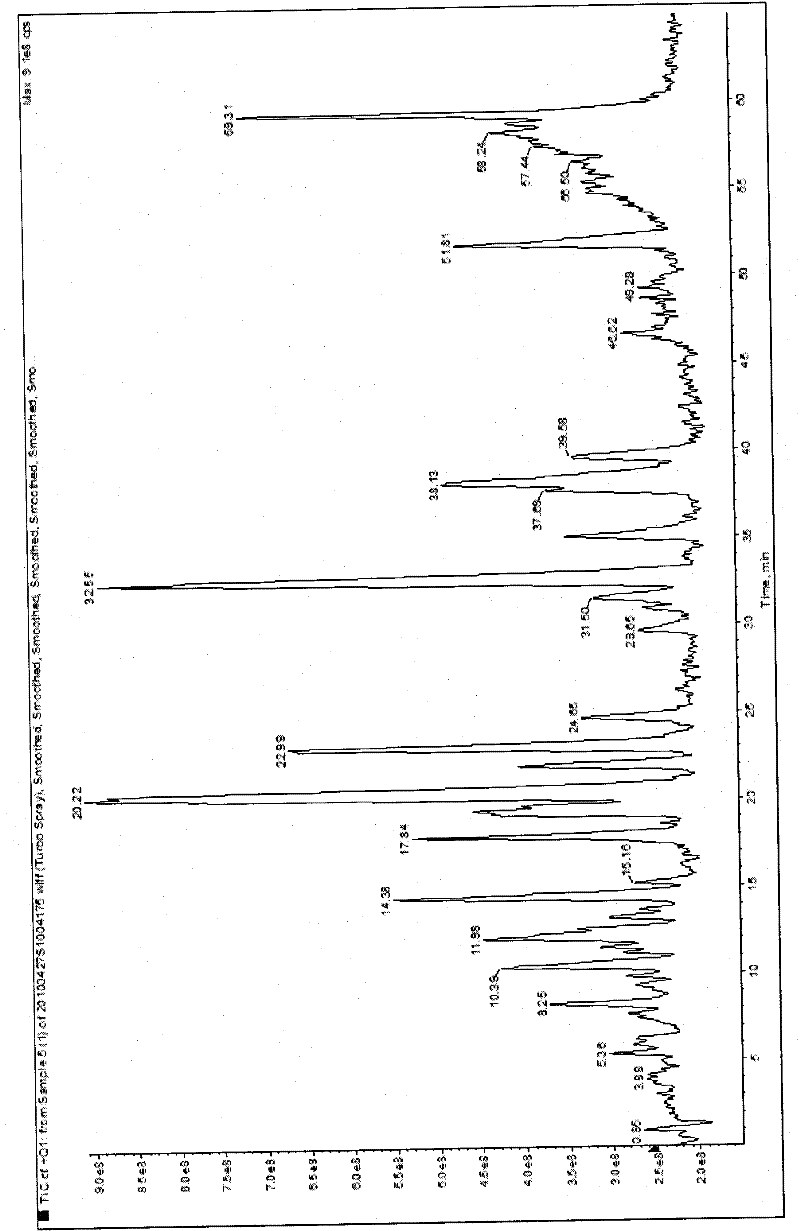

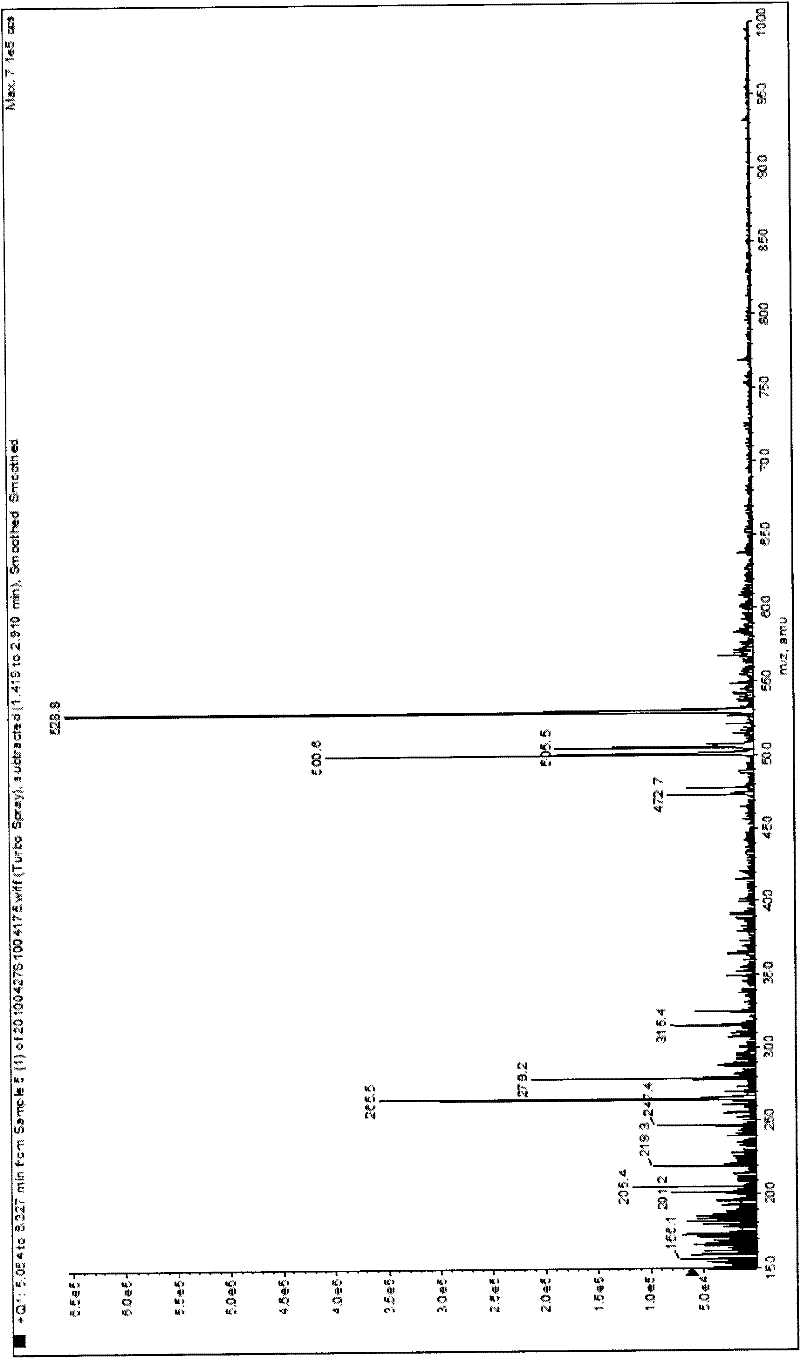

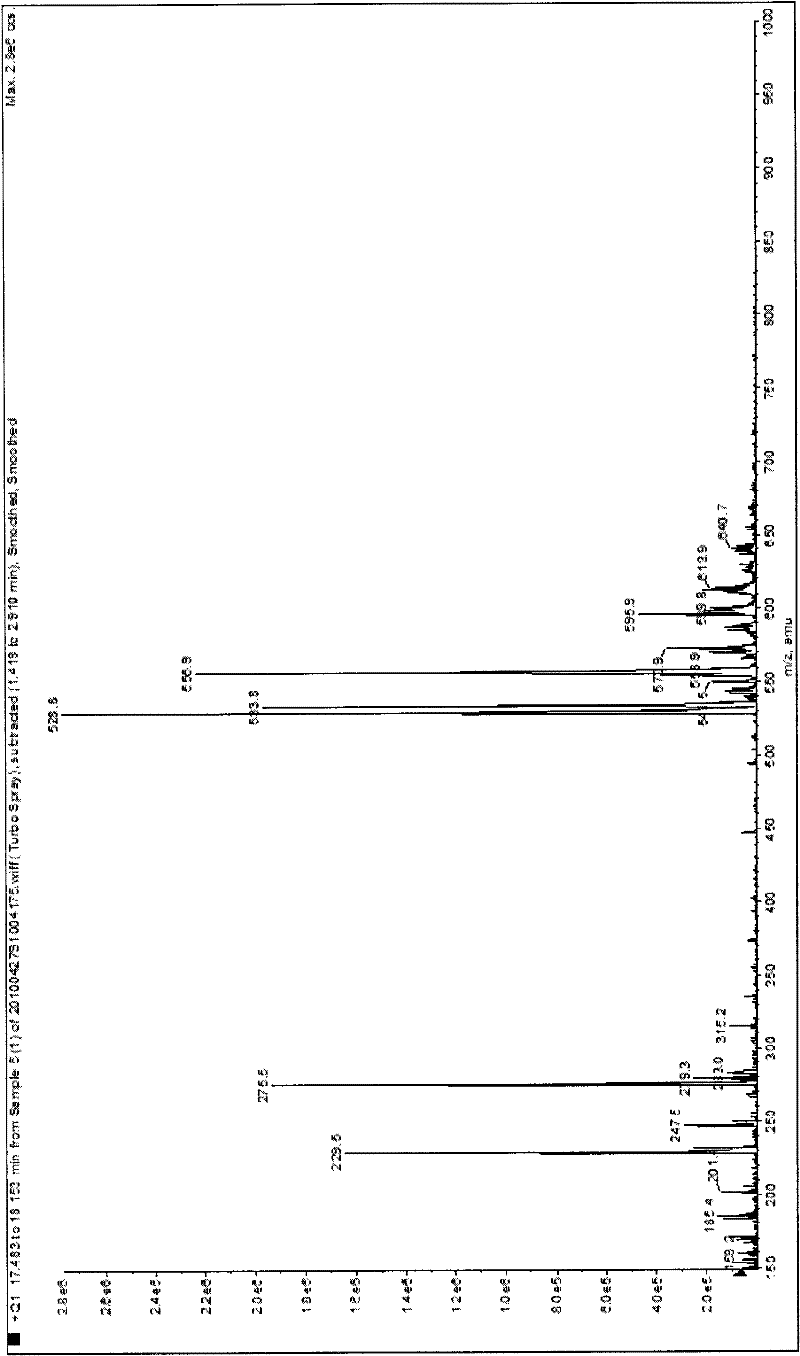

[0073] Detection method is with embodiment 1, and detection result is as follows: by Figure 11 Combined with mass spectrometry Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com