Sectional construction precision control method for cylindrical ultra-deep sea drilling platform

A drilling platform and segmented construction technology, which is applied in ship construction, ship parts, ships, etc., can solve the problems of sub-manufacturing and closing positioning accuracy that cannot meet the ideal requirements, can not be precise and effective, and achieve the strength of the hull Reliability, reduction in the probability of cracks or deformation, effect of guaranteeing hull strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

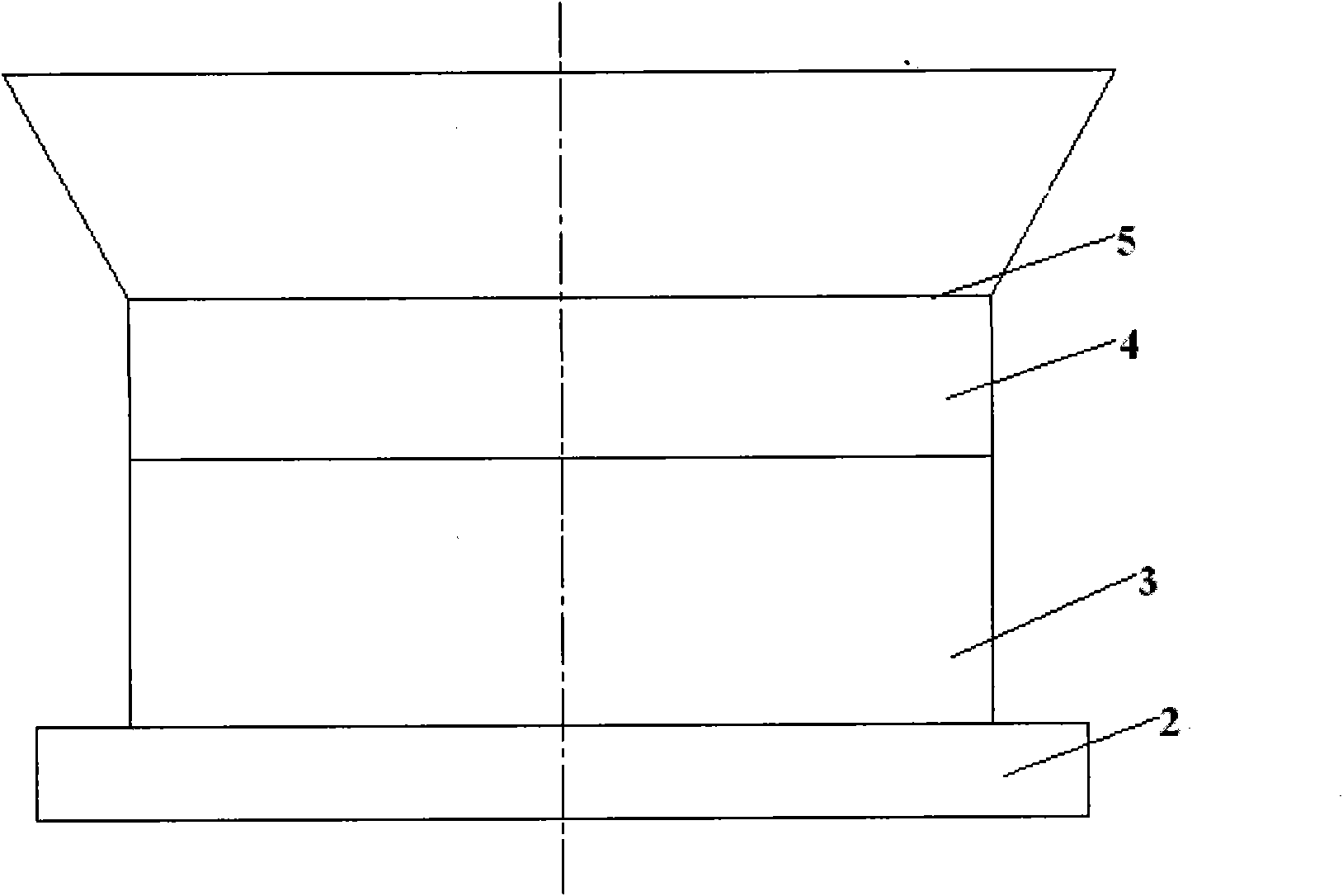

[0034] This embodiment is illustrated with the SEVAN650 cylindrical ultra-deep sea drilling platform. The maximum diameter of the cylinder of this offshore drilling platform is 85 meters, the molded width is 75 meters, and the height of the main body will reach 135 meters. The method of segmental construction accuracy control includes the following steps:

[0035] First, build the platform model: based on experience and combined with the actual situation of the cylindrical ultra-deep sea drilling platform, add 0.1‰~0.35‰ shrinkage data; then load the added shrinkage data into the 3D design software TRIBON, and carry out platform data modeling;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com