Method for surface regulation of silicon material for solar cells

A technology of solar cells and silicon materials, applied in the field of solar cells, can solve the problems of uncontrollable, uneven suede, unsuitable application, etc., and achieve the effects of controllable operation, increasing light absorption area, and ensuring uniformity and regularity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

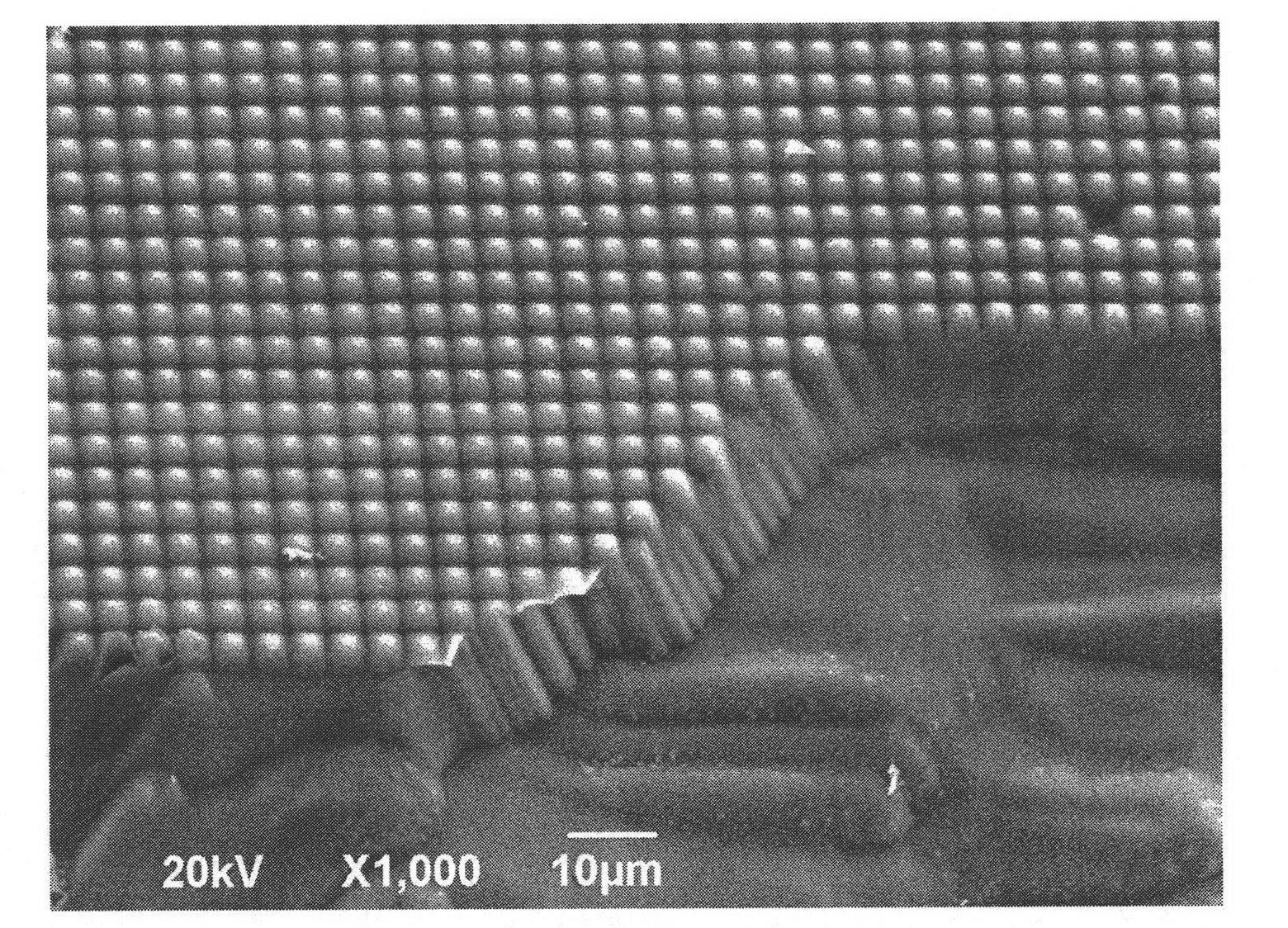

[0017] The object of the present invention is to provide a method for regularizing the surface of a silicon material for solar cells. The method is characterized in that a combination of photolithography, mask technology and alkali wet etching technology is used to deposit a mask layer on the silicon surface before performing alkali wet etching on the silicon surface, and use the mask plate to clean the silicon surface. The surface mask layer is patterned, so that the etching of the silicon surface is selective and controllable.

[0018] A technical scheme of a method for regularizing the surface of a solar cell silicon material in the present invention is:

[0019] Using the principle of corrosion to form a pyramid structure on the silicon surface can increase the light-receiving surface area and reduce the reflectivity of sunlight, but the corrosion method is extremely u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com