A photocatalyst immobilization method on a flexible fiber substrate

A photocatalyst and flexible fiber technology, applied in the field of photocatalysis, can solve problems such as unfavorable photocatalytic reactions, reduce opportunities for reuse of loaded photocatalysts, and limited application range, so as to reduce mass transfer limitations, increase surface area and illumination area, Avoid the effect of high running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

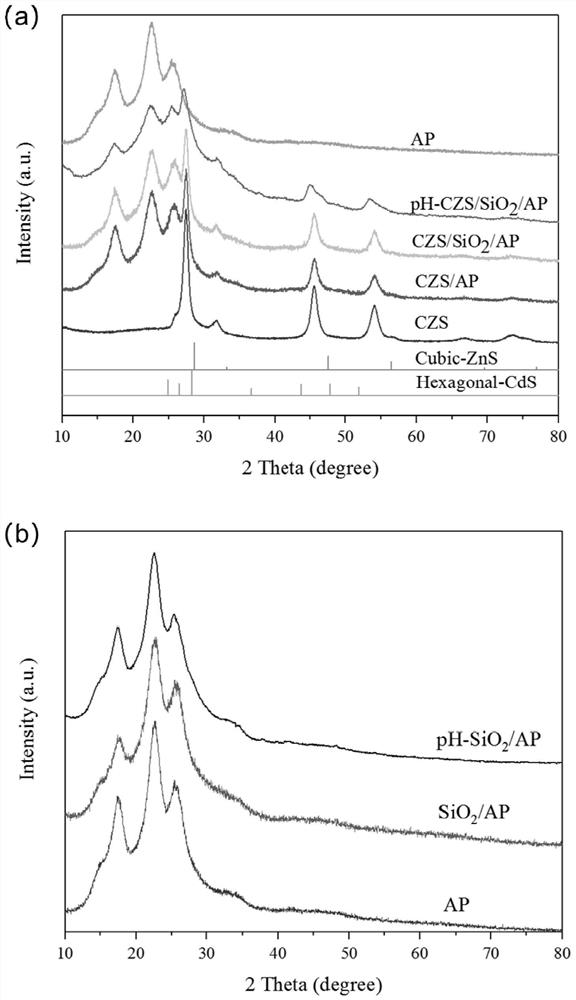

[0045] (1) Add 40mg of CZS photocatalyst and 40mg of silicon dioxide powder with a diameter of 300nm into 5mL of deionized water, disperse evenly by ultrasonic vibration for 30min, prepare a catalyst suspension with a concentration of 8mg / mL, and set aside;

[0046] (2) The flexible carrier material is dust-free paper with water absorption, model 0609 dust-free wiping paper, made of 55% cellulose (native wood pulp) and 45% polyester fiber, and cut it into a size of 5cm*5cm Dimensions, rinsed with deionized water and dried for later use;

[0047] (3) Place the dust-free paper obtained in step (2) flat on the heating platform, and use a pipette gun to take 2.5mL of the catalyst suspension obtained in step (1) and apply it drop by drop on the dust-free paper at a uniform speed. Due to the high-efficiency water absorption of the paper, the liquid droplets will quickly spread to the surrounding area after contacting the dust-free paper, forming a uniformly loaded catalyst liquid fi...

Embodiment 2

[0051] (1) Add 400mg of CZS photocatalyst and 400mg of silicon dioxide powder with a diameter of 300nm into 25mL of deionized water, disperse evenly by ultrasonic vibration for 30min, prepare a catalyst suspension with a concentration of 16mg / mL, and set aside;

[0052] (2) The carrier material is model 0609 dust-free wiping paper, the size is 20cm*20cm, rinsed with deionized water and dried for later use;

[0053] (3) Place a piece of glass parallel to the ground under outdoor sunlight, place the dust-free paper obtained in step (2) on the glass, and take 20 mL of the catalyst suspension obtained in step (1) drop by drop at a constant speed with a pipette gun Drop-coated on dust-free paper, dried under sunlight to prepare the loaded photocatalyst precursor.

[0054] (4) Soak the loaded photocatalyst precursor obtained in step (3) into the configured sodium sulfide / sodium sulfite solution with pH=12 for 5h, then place it on an outdoor wooden board, and dry it under sunlight to...

Embodiment 3

[0057] (1) 80mg TiO 2 (P25) Photocatalyst and 80 mg of silicon dioxide powder with a diameter of 500 nm were added to 10 mL of deionized water, disperse evenly by ultrasonic vibration for 30 min, and prepared into a catalyst suspension with a concentration of 8 mg / mL for later use;

[0058] (2) Use model 0609 dust-free wiping paper as the carrier material, cut it into a size of 5cm*5cm, wash it with deionized water and dry it for later use;

[0059] (3) Place the dust-free paper obtained in step (2) flat on the heating platform, and use a pipette gun to take 2.5mL of the catalyst suspension obtained in step (1) and apply it drop by drop on the dust-free paper at a uniform speed. Due to the high-efficiency water absorption of the paper, the liquid droplets will quickly spread to the surrounding area after contacting the dust-free paper, forming a uniformly loaded catalyst liquid film, and dried at 60°C for 20 minutes to prepare the loaded photocatalyst precursor.

[0060] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com