Electrode structure and light emitting element thereof

A light-emitting element and electrode structure technology, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of reducing the reliability of light-emitting diodes and overheating, and achieve the effects of avoiding overheating and reducing forward voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

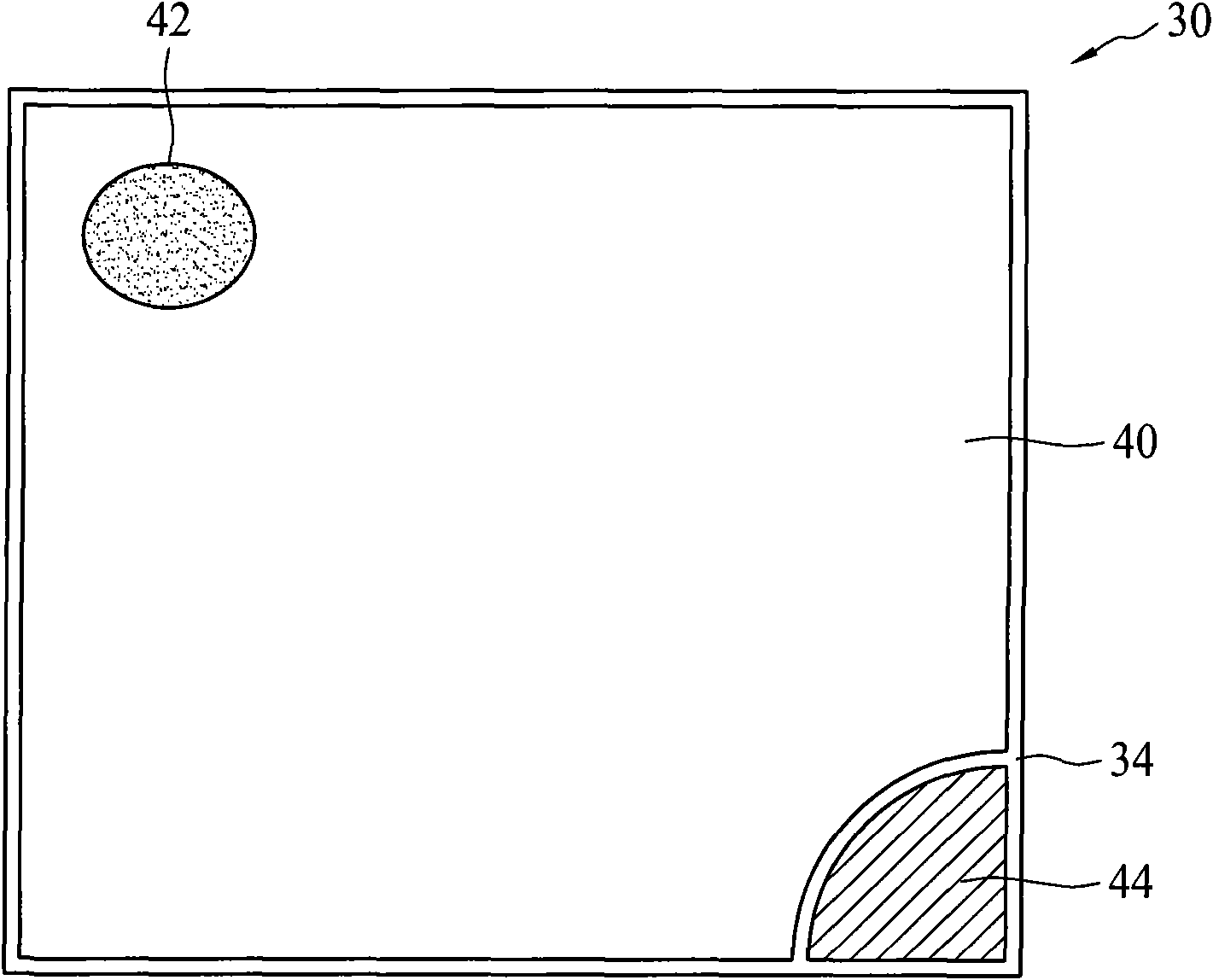

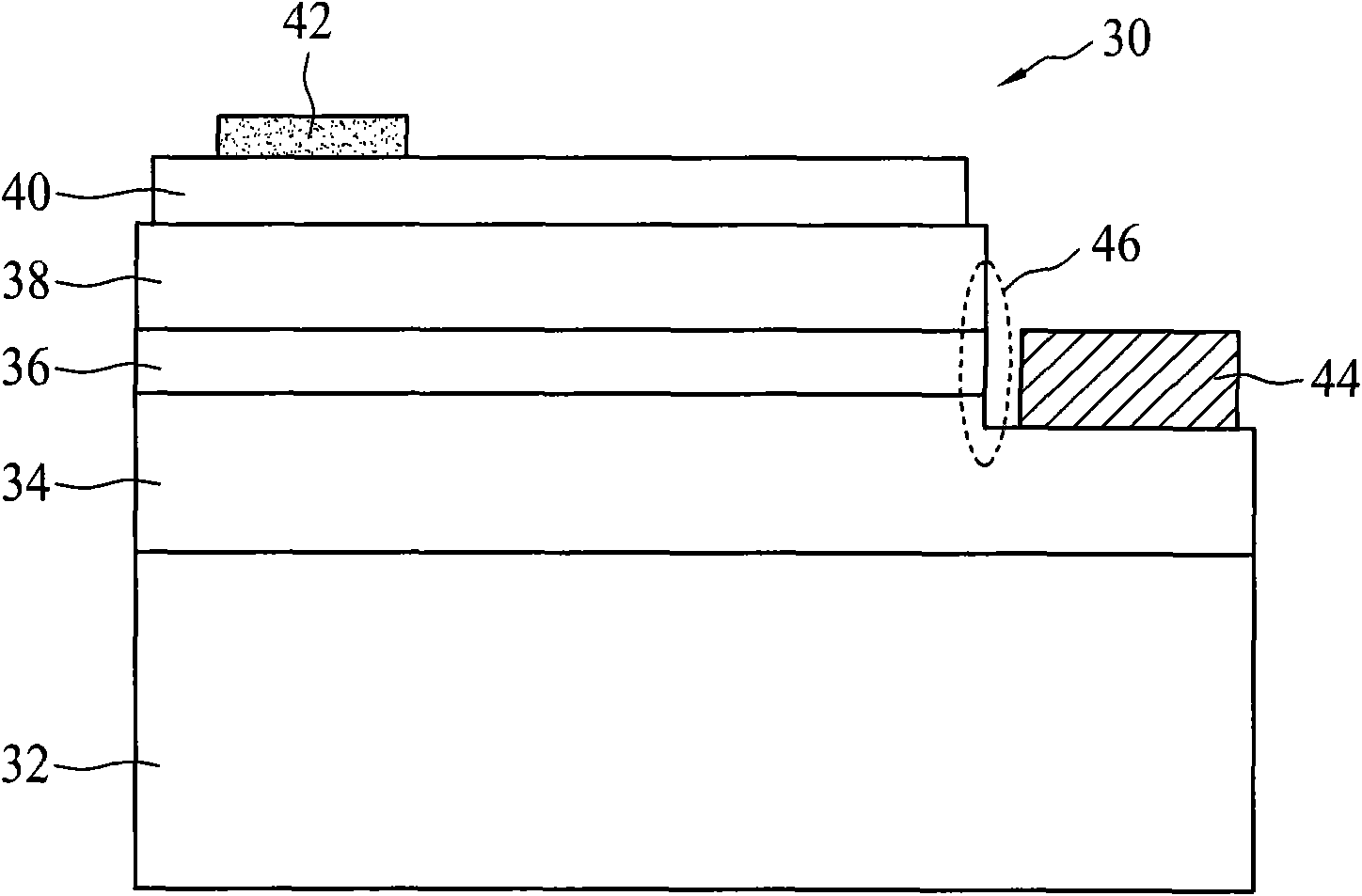

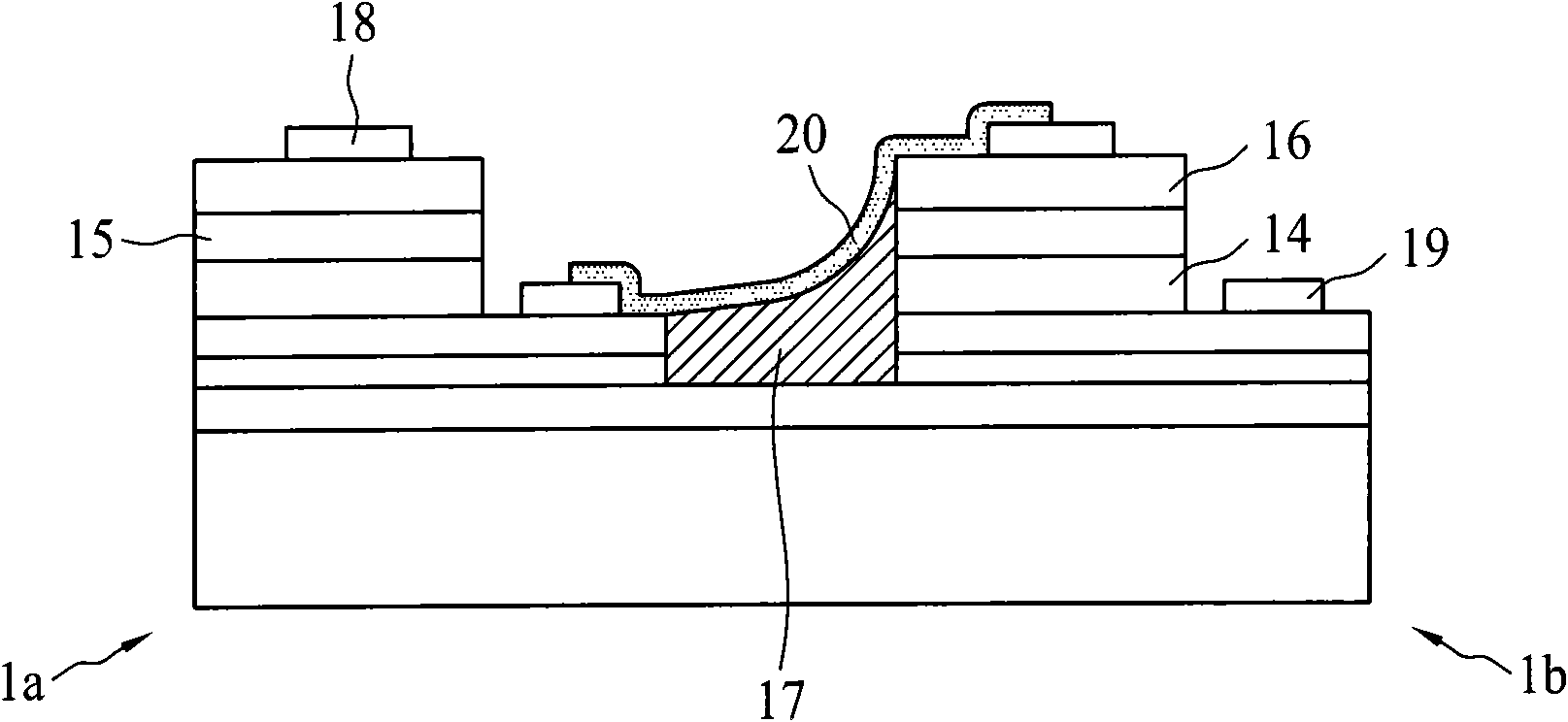

[0104] Figure 5 to Figure 7 Shown is a light emitting element 50 according to a first embodiment of the present invention. Figure 5 is a plan view of the light emitting element 50, Figure 6 yes Figure 5 Sectional view along section line A-A, Figure 7 It is an equivalent circuit diagram of the light emitting element 50 electrically connected to a power source 92 . refer to Figure 5 and Figure 6 The light-emitting element 50 includes a substrate 52, a stack structure 62 disposed on the substrate 52, at least one groove 64 disposed in the stack structure 62, at least two first electrodes disposed in the groove 64 70 and at least two second electrodes 80 disposed on the stack structure 62 . The stacked structure 62 includes a first conductive type (n-type) semiconductor layer 54 disposed on the substrate 52, a light emitting structure 56 disposed on the first conductive type semiconductor layer 54, and a light emitting structure disposed on the light emitting structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com