Air respirator filling pump with cylinder body being provided with cooling device

A cooling device and respirator technology, applied in the direction of pumps, multi-stage pumps, pump components, etc., can solve problems such as endangering personal safety, restricting rapid development, increasing production costs, etc., to reduce temperature, improve operating life and reliability. , the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

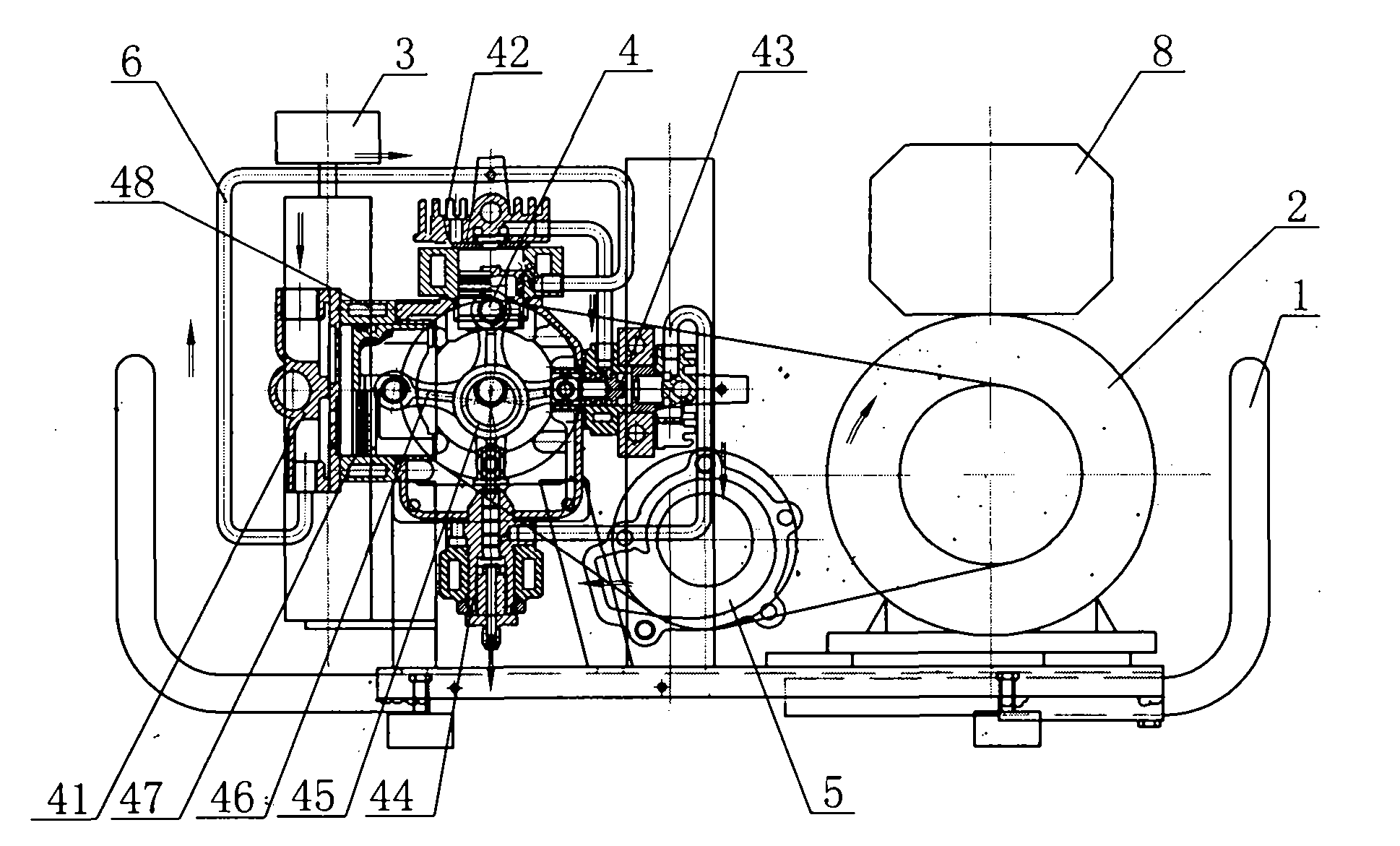

[0023] exist figure 1 Among them, an air respirator filling pump with cylinder cooling device is composed of a compressor device 4, a driving motor 2, a machine base 1 and the like. The compressor device 4 is composed of a four-stage compression cylinder, a four-stage safety valve, a four-stage filter and oil-water separation air purification device 3, a condensed water discharge valve, an air pipe 6, and a pressure maintaining valve. A fan is installed on the counterweight at the 45 end of the crankshaft of the air filling pump compressor, and the four-stage compression cylinder increases the air pressure step by step from 0; each stage of the cylinder is composed of a cylinder body and a cylinder valve head, and there is a piston in the cylinder body 47, components such as connecting rod 46. The cylinder valve head is the top of the cylinder, and the inner side is equipped with an intake valve and a pressure plate valve. The opening and closing of the valve is automatically...

Embodiment 2

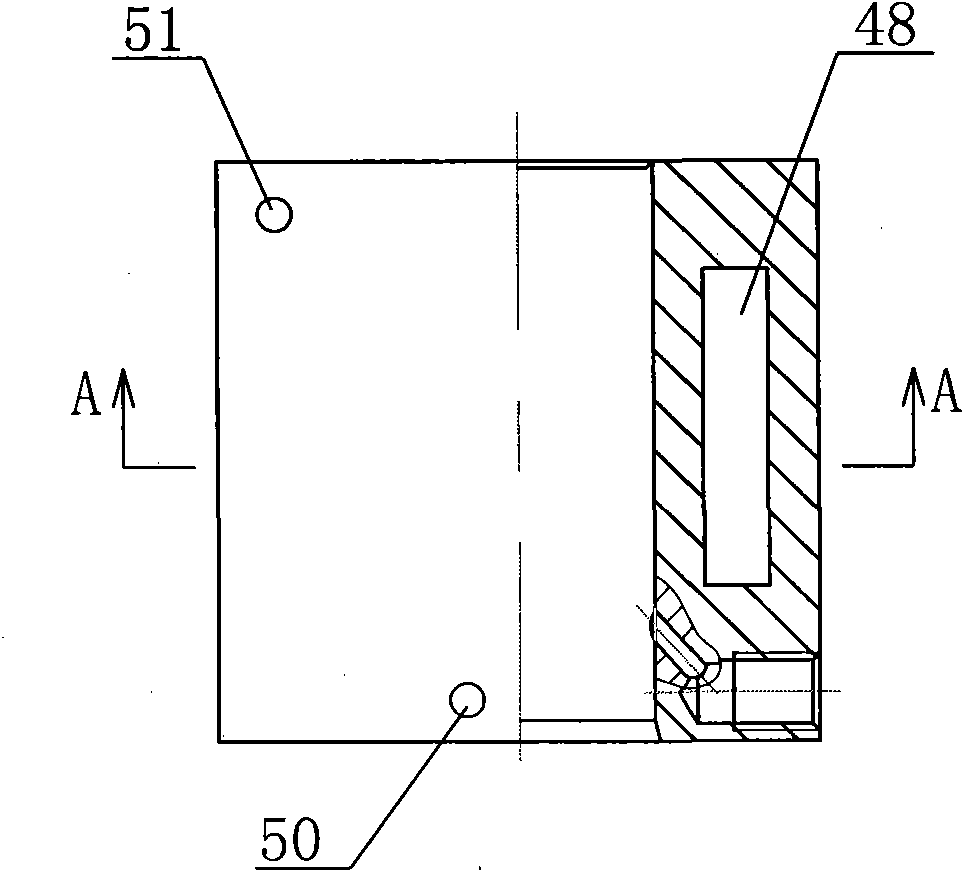

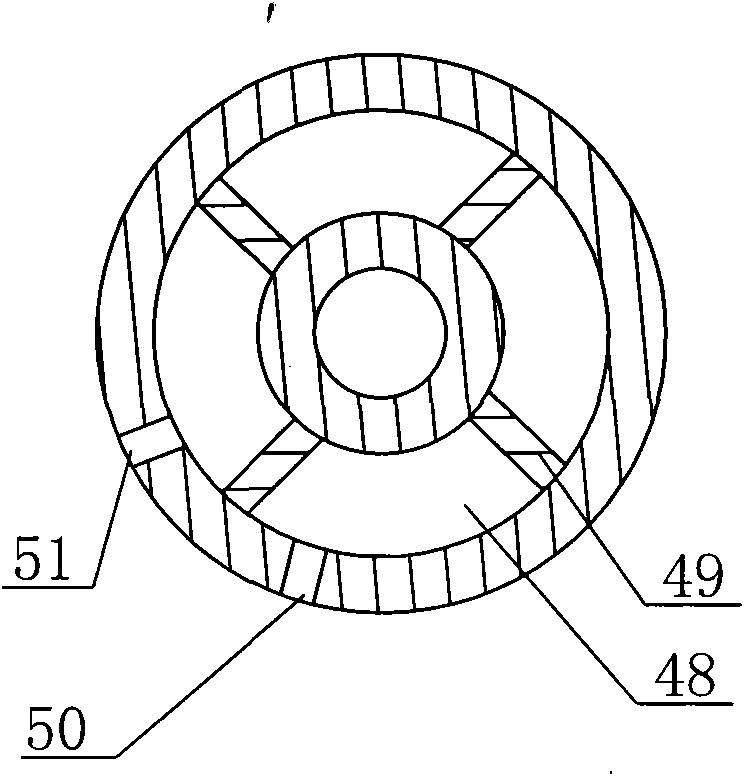

[0025] The embodiment of the present invention is not provided with water tanks, water pumps, etc., and other overall structures are the same as those of the first embodiment. figure 1 resemblance. The cylinder block structure of this embodiment is the same as figure 2 and image 3 combine Figure 5Among them, the input port of the cylinder body of the first-stage cylinder 41, the cylinder body of the second-stage cylinder 42, the cylinder body of the third-stage cylinder 43, and the cylinder body diversion groove 48 of the fourth-stage cylinder 44 is connected into a total input port through the conduit 7, and the first-stage The cylinder body of cylinder 41, secondary cylinder 42, the cylinder body of three-stage cylinder 43, the input port of the cylinder body diversion groove 48 of four-stage cylinder 44 are connected into a total output port by conduit. When in use, the main input port is connected with the tap water, and the cooled water is discharged from the main o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com