Method for preparing functional acrylate copolymer emulsion for toughening nylon 6

A technology of acrylates and acrylates, which is applied in the field of preparation of functionalized acrylate copolymer emulsions for nylon 6 toughening, can solve the problems of poor interface bonding between phases, difficulty in controlling the particle size and distribution of dispersed phases, etc. To achieve the effect of improving the notched impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] a. Pre-emulsification of nuclear layer monomer

[0044] First, add 0.3g of anionic emulsifier sodium dodecyl diphenyl ether sulfonate and 140g of deionized water into a 500ml four-neck flask, and mix and stir for 20min; then add 10g of butyl acrylate into the reaction flask, and mix and stir for 10min , that is, the pre-emulsion of the core layer monomer is obtained and set aside.

[0045] b. Pre-emulsification of shell monomer

[0046] Take three 300ml beakers, add 1.88g of anionic emulsifier sodium dodecyl diphenyl ether sulfonate, 150g of butyl acrylate, 0.75g of allyl methacrylate and 0.057g of tert-dodecyl mercaptan into the beakers in sequence 1, and then place it on an electromagnetic stirrer and mix and stir for at least 20 minutes to obtain the first monomer pre-emulsion of the shell layer; add 0.1g of anionic emulsifier sodium dodecyl diphenyl ether sulfonate and 8g of methyl methacrylate In the beaker 2, place it on an electromagnetic stirrer and mix and st...

Embodiment 2~9

[0058] The specific steps are the same as in Example 1, but the changes in the quality of the seed stage emulsifier and crosslinking agent used in Examples 2 to 9 are specifically shown in Table 1.

[0059] Formulations of the seed stage emulsifier and crosslinking agent in the preparation examples 2-9 of the functionalized acrylate emulsion of the multilayer core-shell structure in Table 1

[0060]

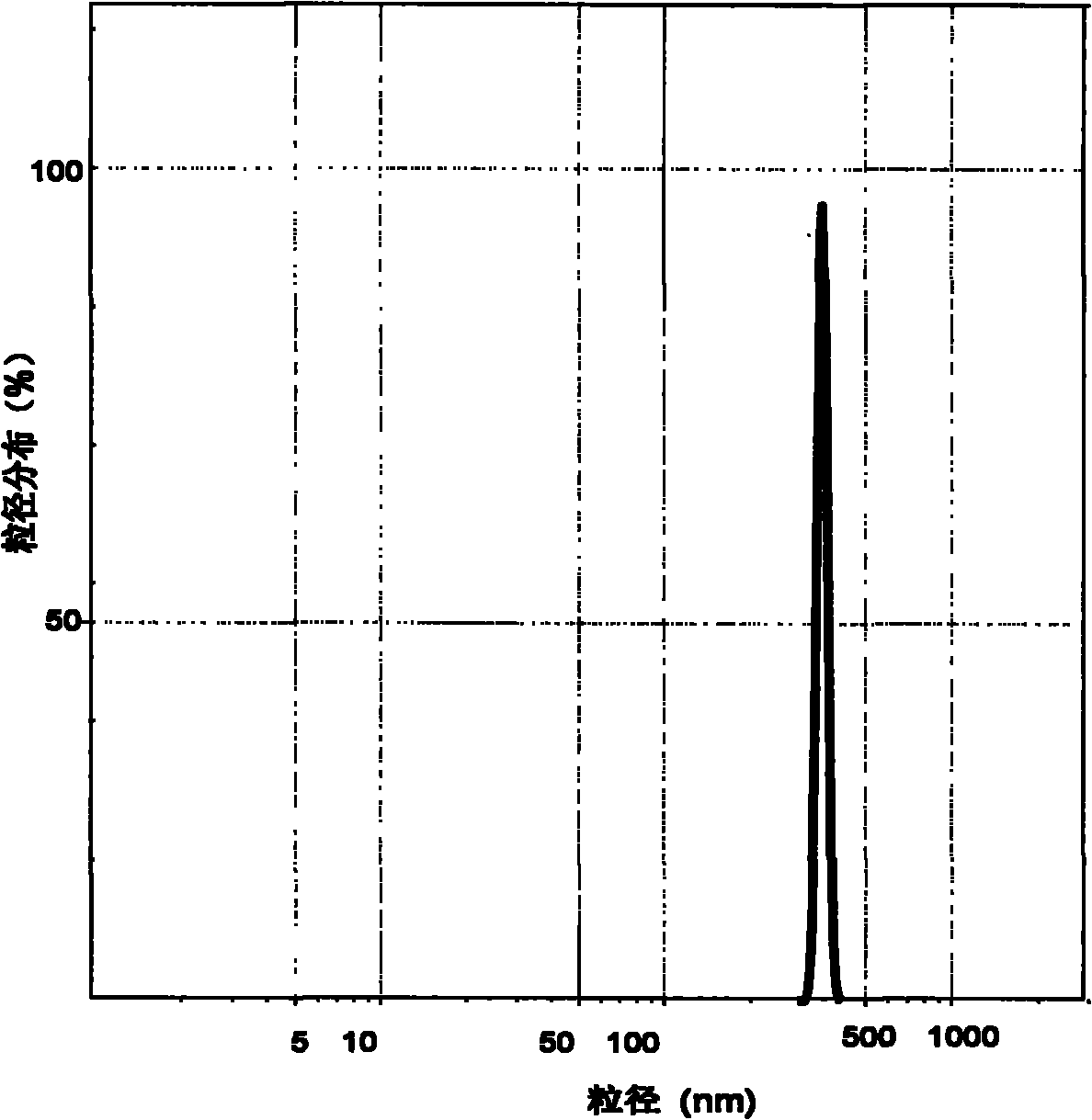

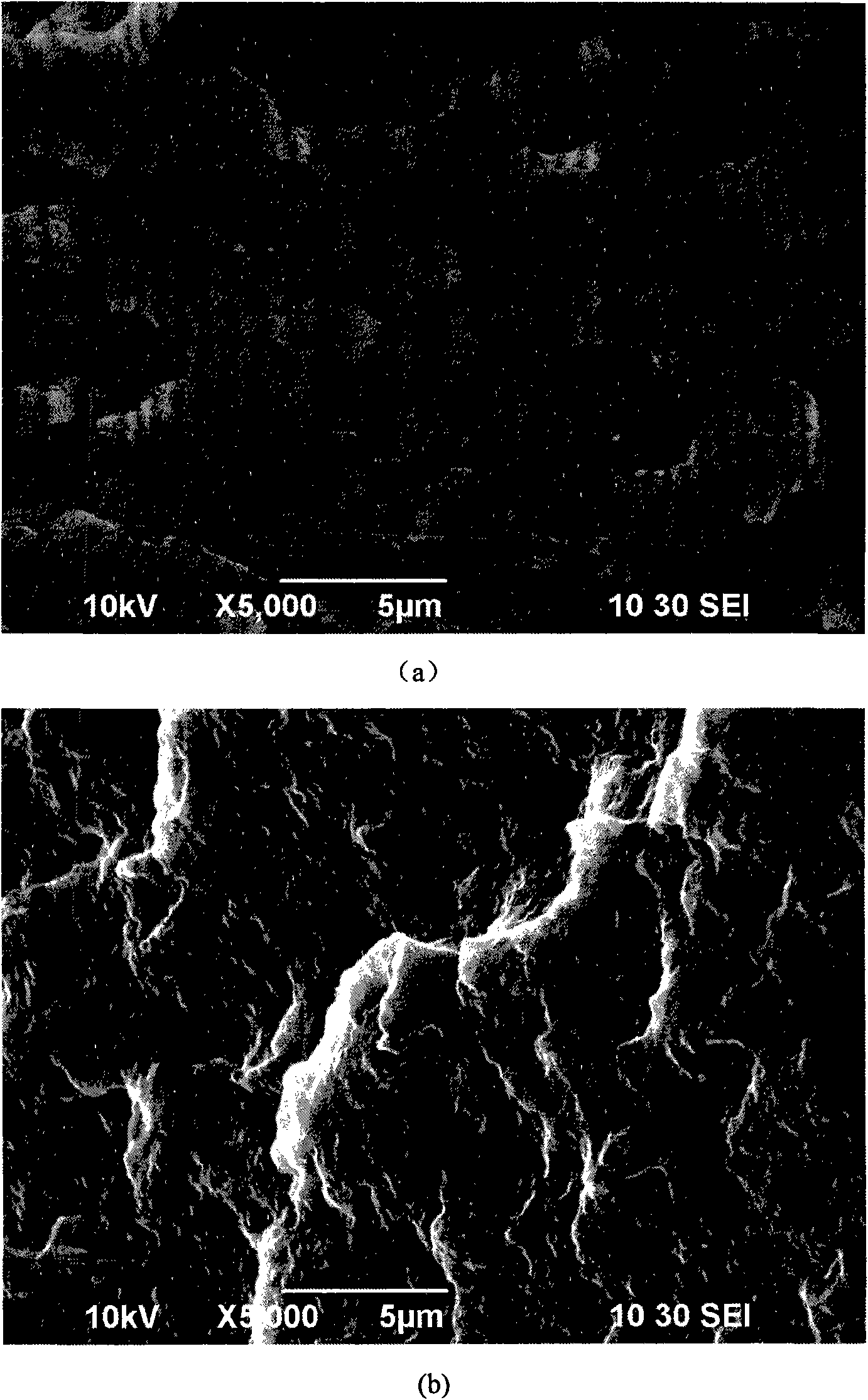

[0061] The parameters of the functionalized acrylate polymer emulsion in the above examples are listed in Table 2, and the mechanical properties of these functionalized acrylate polymers modified PA6 are listed in Table 3.

[0062] Table 2 The parameters of the functionalized acrylate emulsion of multilayer core-shell structure

[0063]

[0064] Table 3 Mechanical properties of functionalized acrylate polymer and nylon 6 blends with multilayer core-shell structure

[0065]

[0066] As can be seen from Table 2, when using this invention to prepare the functionalized acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com