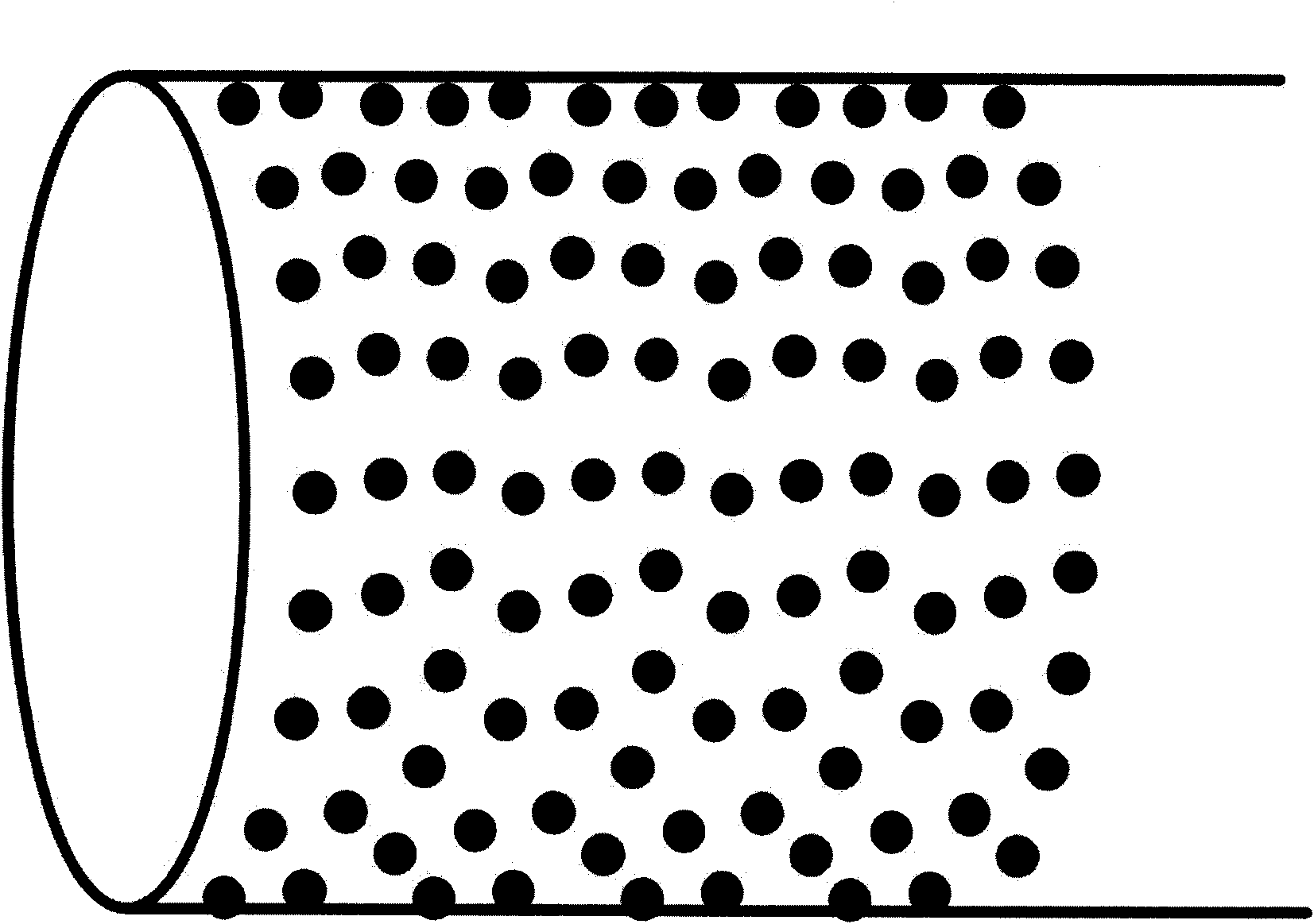

Surface roughen processing method for laser rollers with irregular deflected focus light spot and device

A processing device and processing method technology, which is applied to laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of cold-rolled steel plates without obvious linear distribution and strain, and achieve simple structure, convenient maintenance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

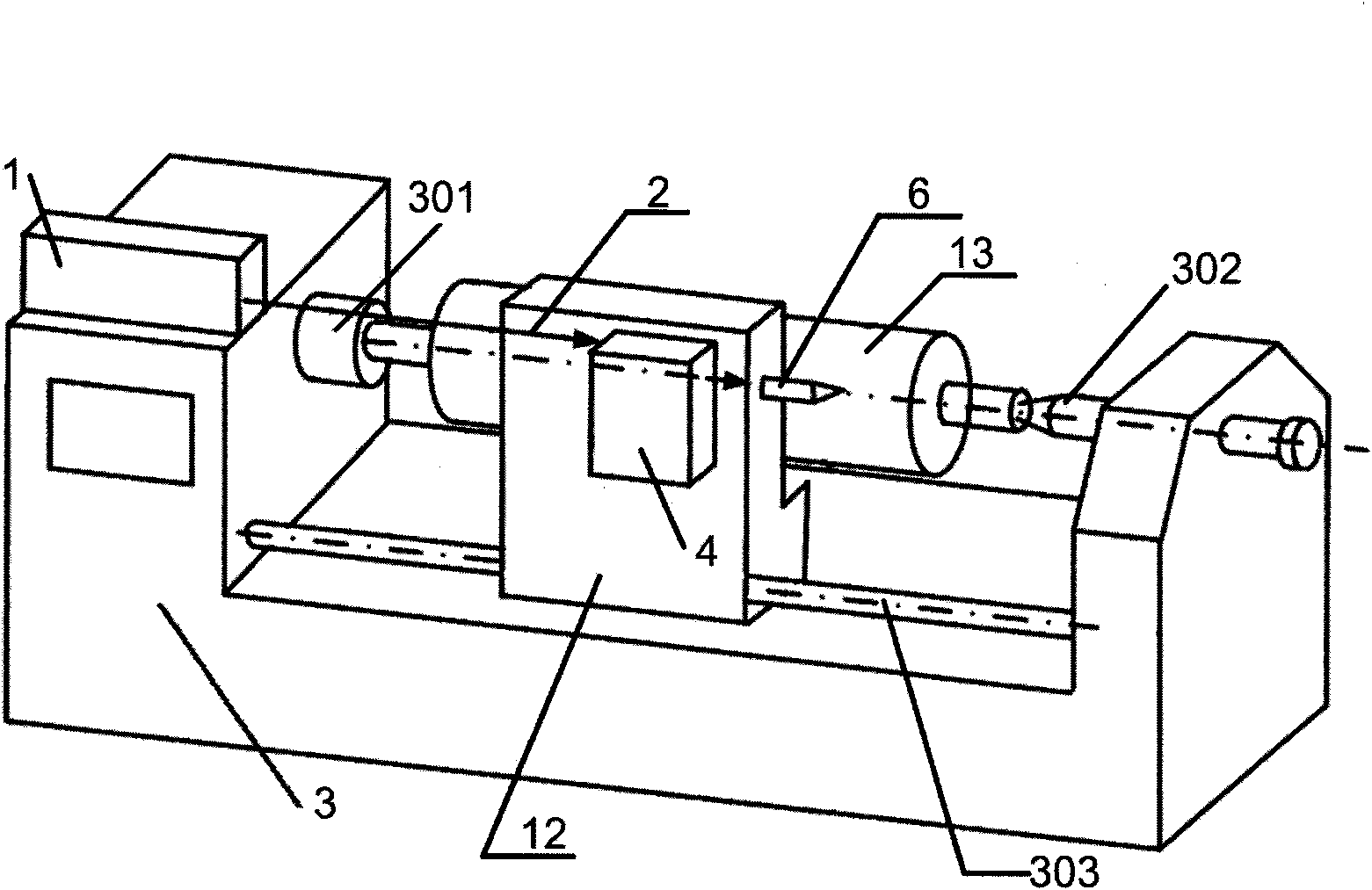

[0044] Example: such as figure 2 , image 3 and Figure 5 Shown is a specific embodiment of the laser roller type surface roughening processing device with irregular deflection of the focused light spot provided by the present invention, including a high-power pulsed laser 1 and a numerically controlled machine tool 3, the bed of said numerically controlled machine tool 3 is equipped with The working platform 12 driven by the translation guide rail 303 and the roll shaft 301 and the top 302 for installing the roll 13 parallel to the translation guide rail 303, the pseudo-random acousto-optic deflection system 4 and the focusing mechanism 6 are installed on the said work platform 12, said Pseudo-random acousto-optic deflection system 4 is composed of acousto-optic deflector 401, acousto-optic deflection driver 402, pseudo-random signal generator 403 and computer controller 404 that are electrically connected in sequence. Controlled by the electrical signal output by the acou...

Embodiment 2

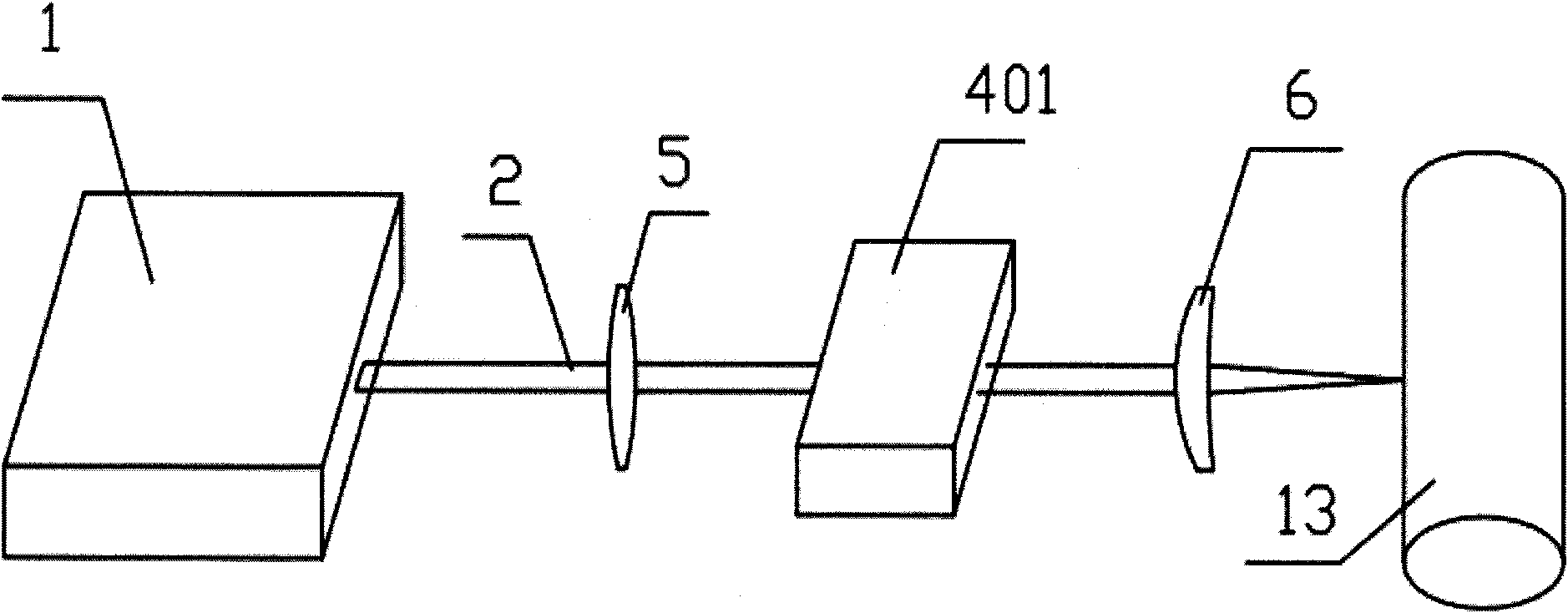

[0054] Example 2: specific combination Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the focusing mechanism 6 is placed at the front of the acousto-optic deflector 401, and the focusing mechanism 6 still adopts a transmissive focusing lens, while the rest of this embodiment is the same as that of the embodiment 1. In this way, the pulsed laser beam 2 emitted by the high-power pulsed laser 1 passes through the optical element system 5 and then enters the focusing mechanism 6 to focus, and then deflects through the acousto-optic deflector 401 controlled by a pseudo-random signal to roughen the surface of the roll 13. processing. The equivalent focal length of the focusing mechanism 6 is longer than that of Embodiment 1, because the acousto-optic deflector 401 is placed between the focusing mechanism 6 and the surface of the roller 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com