Method for quickly removing metronidazole by utilizing nanoscale zero-valent iron and application thereof

A nano-zero-valent iron and metronidazole technology, applied in the field of environmental chemistry, can solve problems such as expensive radiation sources, large infrastructure investment, and difficult recovery of photocatalysts, achieving mild reaction conditions, simple reaction processes, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

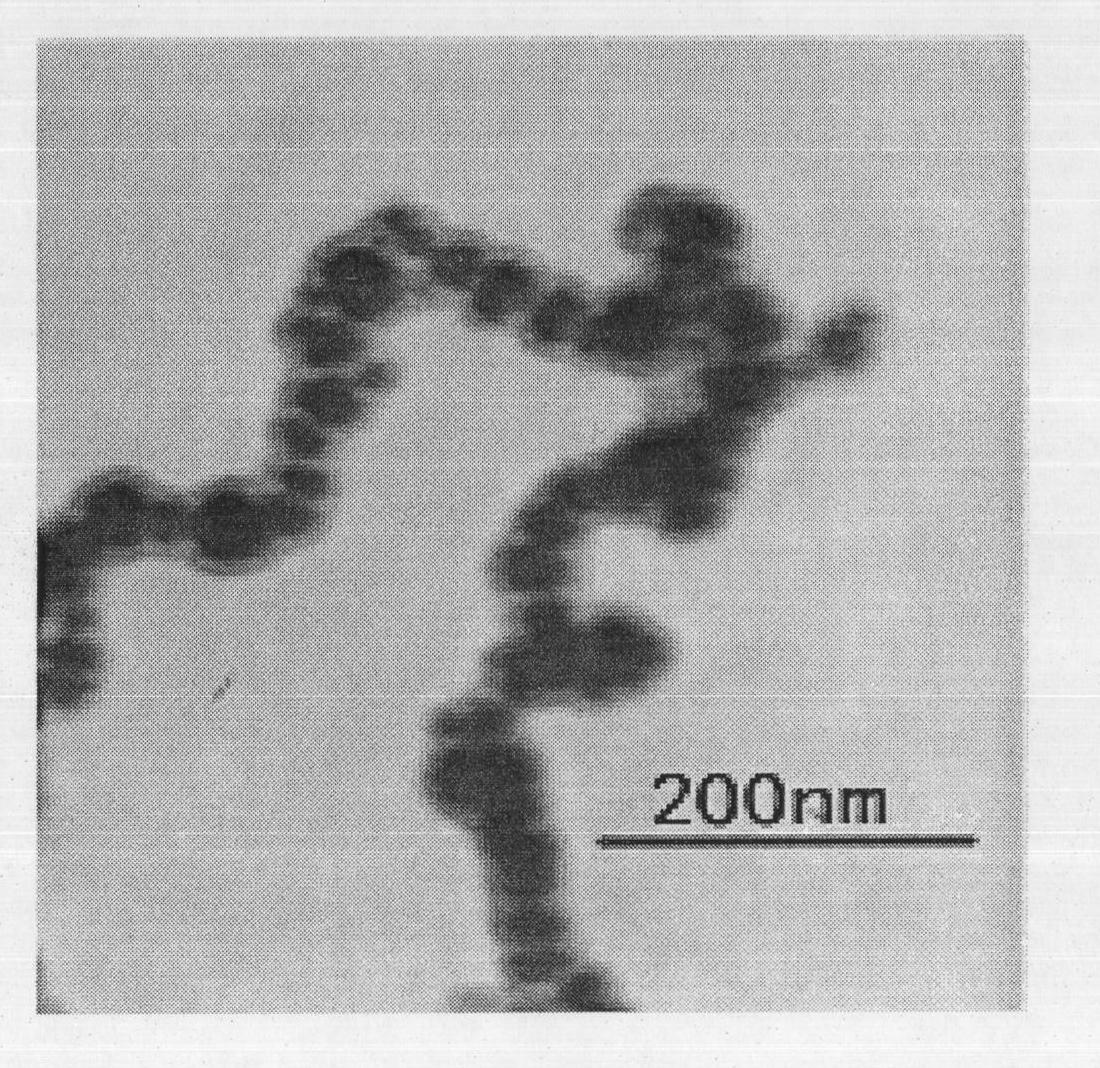

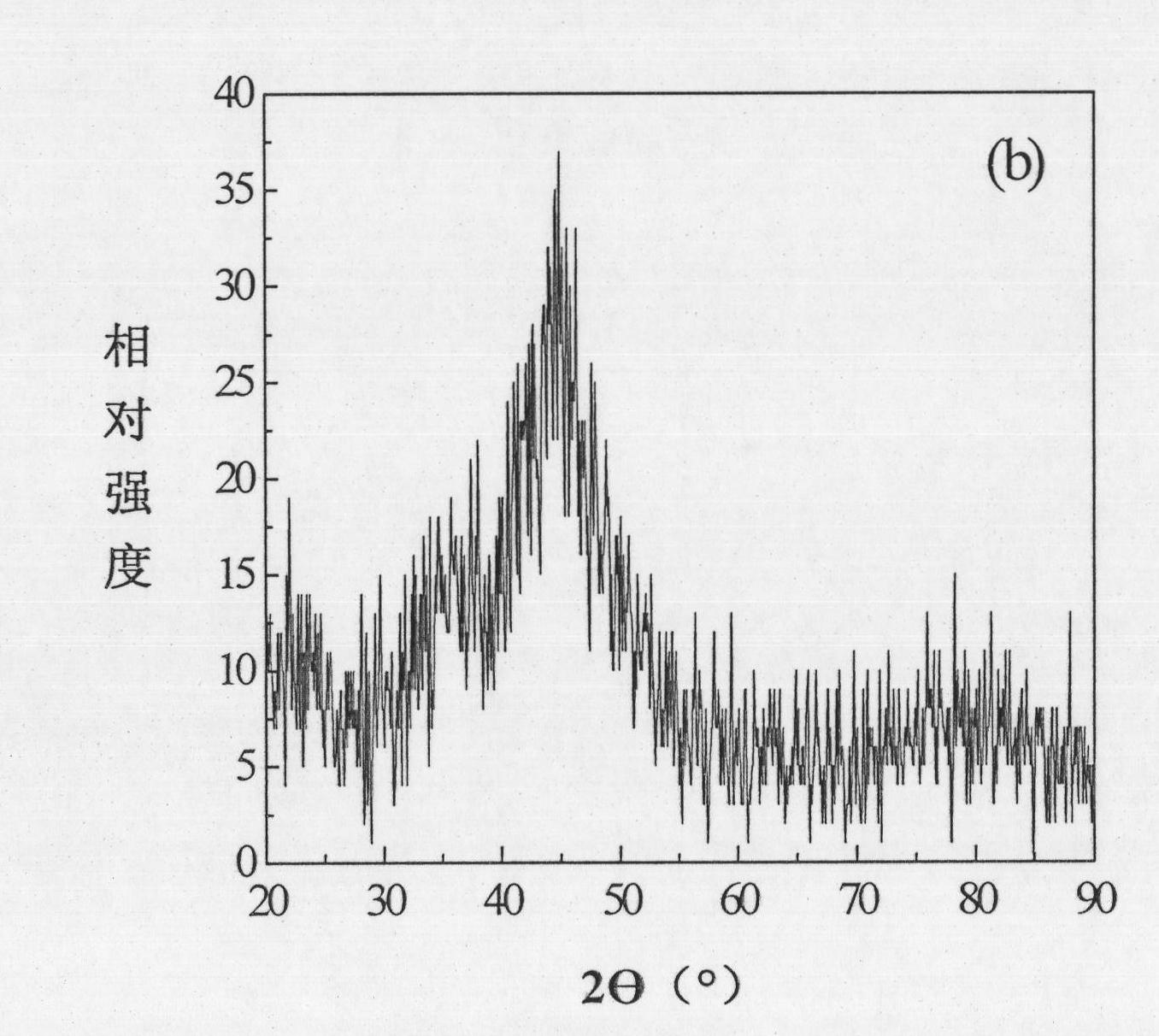

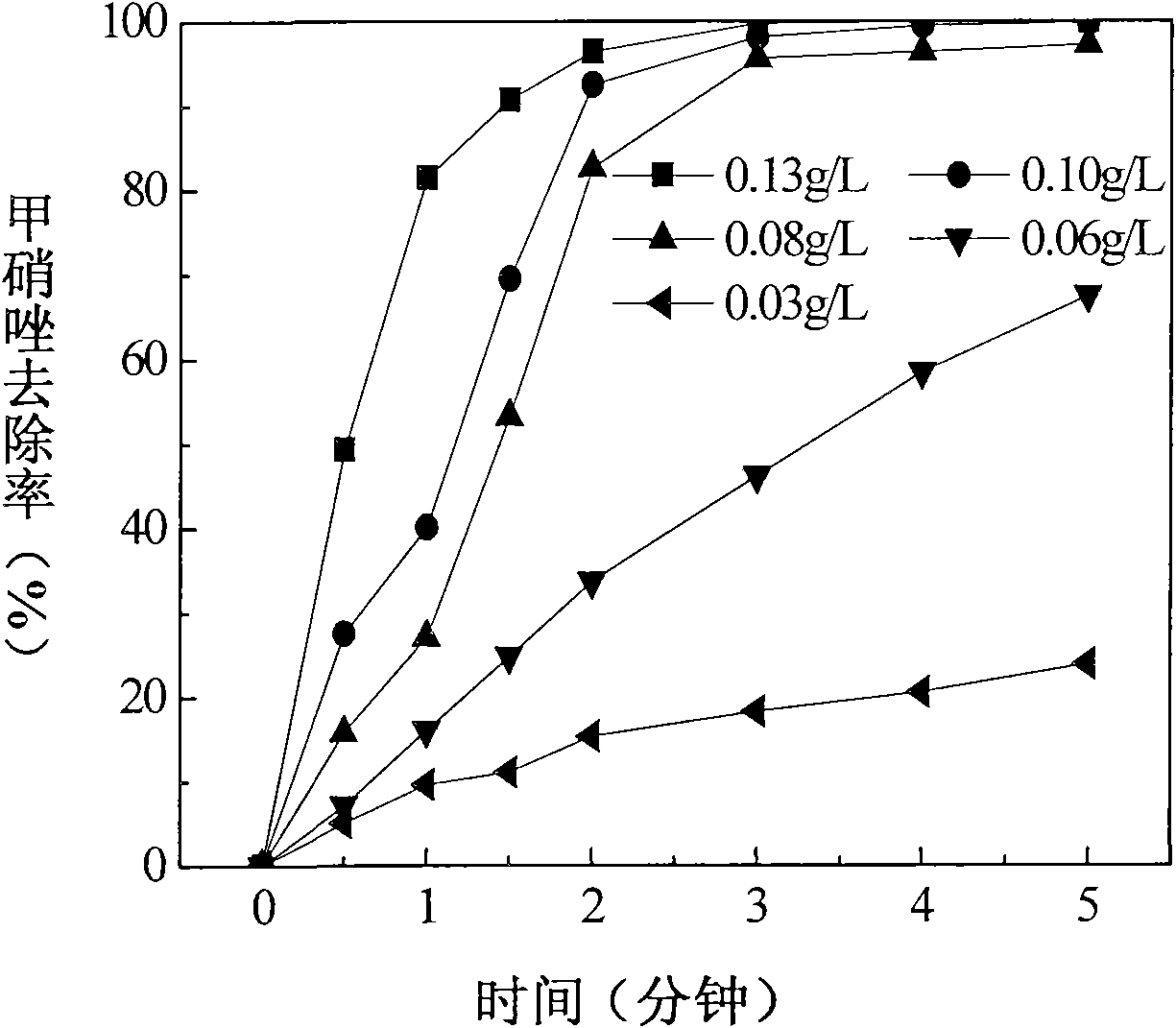

[0032] (1) Preparation of nano-zero-valent iron: The preparation of nano-zero-valent iron adopts a liquid phase chemical reduction method, and uses polyvinylpyrrolidone as a dispersant, and then uses FeSO 4 ·7H 2 O and excess NaBH 4 The zero-valent iron particles prepared by reaction and reduction have good dispersion effect and are not prone to agglomeration. Specific steps: Deionized water for solution preparation is first charged with N 2 30min to remove the dissolved oxygen in the solution, and then used to prepare a 30% ethanol aqueous solution. Weigh 0.55g FeSO 4 ·7H 2 O is dissolved in 100ml of 30% ethanol aqueous solution to prepare 0.02mol / L FeSO 4 ·7H 2 O aqueous solution, and then add polyvinylpyrrolidone (0.11g) at a mass ratio of 1:1 (iron content in iron salt: PVP K-30, m / m), and mechanically stir to make it fully mixed and dissolved. Weigh 0.25g NaBH 4 Dissolve it with 100ml of 30% ethanol aqueous solution to prepare 0.06mol / L NaBH 4 Aqueous solution. Under the ...

Embodiment 2

[0037] (1) Preparation of nano-zero-valent iron: the preparation method of nano-zero-valent iron in this embodiment is the same as that of the above-mentioned embodiment 1(1).

[0038] (2) Nano-zero-valent iron treatment of metronidazole under different initial pH conditions: adjust the initial pH of the metronidazole solution with an initial concentration of 80 mg / L with HCl or NaOH, so that the initial pH of the solution is 3-9 . Take 300mL of each concentration, then add 30mg of nano-zero-valent iron, and react under electric stirring at 180rpm at different time intervals. Take 2-3mL water samples from the bottle and filter through a 0.45μm filter membrane before using high performance liquid chromatography. Determine the concentration of residual metronidazole antibiotic. The result is Figure 4 It is shown that even under the condition that the pH value of the system changes greatly, a higher removal rate can still be achieved, all above 85%, and the removal efficiency is h...

Embodiment 3

[0040] (1) Preparation of nano-zero-valent iron: the preparation method of nano-zero-valent iron in this embodiment is the same as that of the above-mentioned embodiment 1(1).

[0041] (2) Nano zero-valent iron and commercial iron powder (>99%, 3m 2 / g, the average particle size is 69μm, purchased from Tianjin Komeo Chemical Reagent Co., Ltd.) Act on metronidazole: 300ml of metronidazole solution with an initial concentration of 80mg / L (without adjusting the initial pH of the solution) , Its initial pH = 5.60) was put into nano zero-valent iron and commercial iron powder, so that the dosage of both are 0.1g / L. The reaction was carried out under electric stirring at a rotation speed of 180 rpm, and 2-3 mL of water samples were taken from the bottle at different intervals and filtered through a 0.45 μm filter membrane. The concentration of the residual metronidazole antibiotic was determined by high performance liquid chromatography. The response result is like Figure 5 As shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com