Adhered film

A thin film and sticking technology, which is applied in decorative arts, techniques for producing decorative surface effects, coatings, etc., can solve the problems that the release layer and the carrier layer cannot be reused, the production cost is high, and the hardened layer is worn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

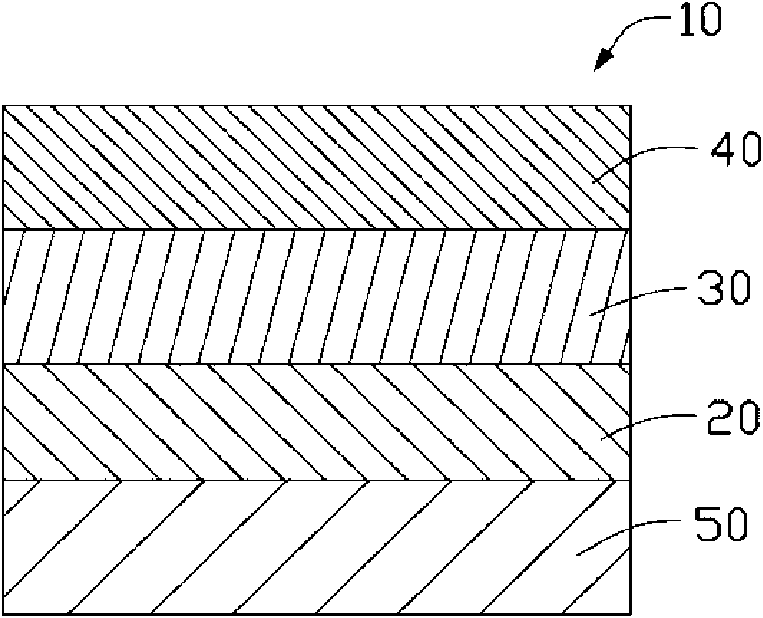

[0016] see figure 1 , the first preferred embodiment of the adhesive film 10 with an anti-reflection layer of the present invention, which includes an adhesive layer 20 , a base layer 30 and an anti-reflection layer 40 .

[0017] The adhesive layer 20 has the effect of combining the attached film 10 with a base material 50 made of molding resin. The adhesive layer 20 is preferably made of acrylic resin, nitrocellulose resin, polyamine-based Formate resin, chlorinated rubber resin, vinyl chloride-vinyl acetate copolymer resin, polyamide resin, polyester resin, epoxy resin, polycarbonate resin, olefin resin and acrylonitrile-butylene- Styrene resin is made of one or two or more materials, so that the adhesive layer 20 can achieve a better overall effect in terms of adhesiveness and post-printing drying. The method for forming the adhesive layer 20 may be any general printing method such as gravure printing, screen printing, and offset printing, or methods such as spraying or br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com