Improved structural sandwich plate panels and methods of making the same

A sandwich panel and component technology, applied in the field of ships, offshore structures and buildings, can solve the problems of low thermal conductivity of concrete slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

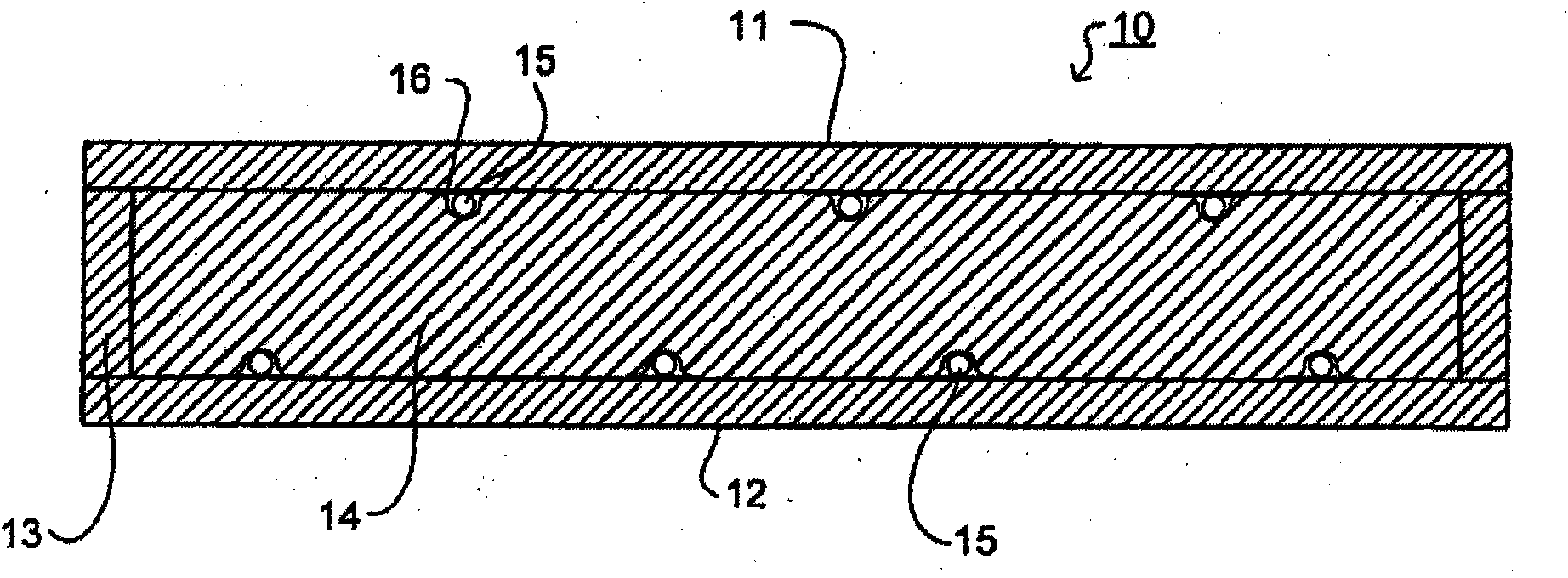

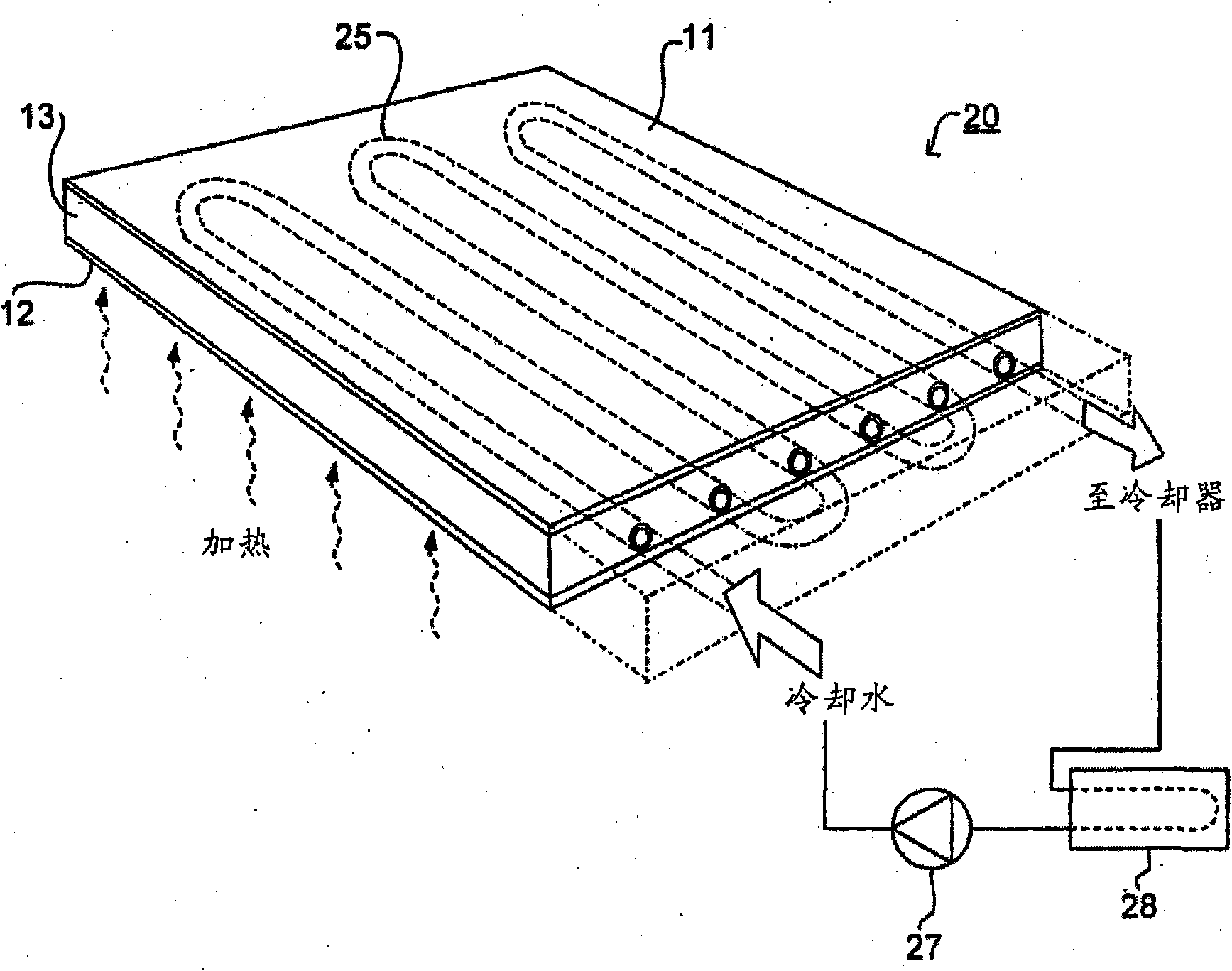

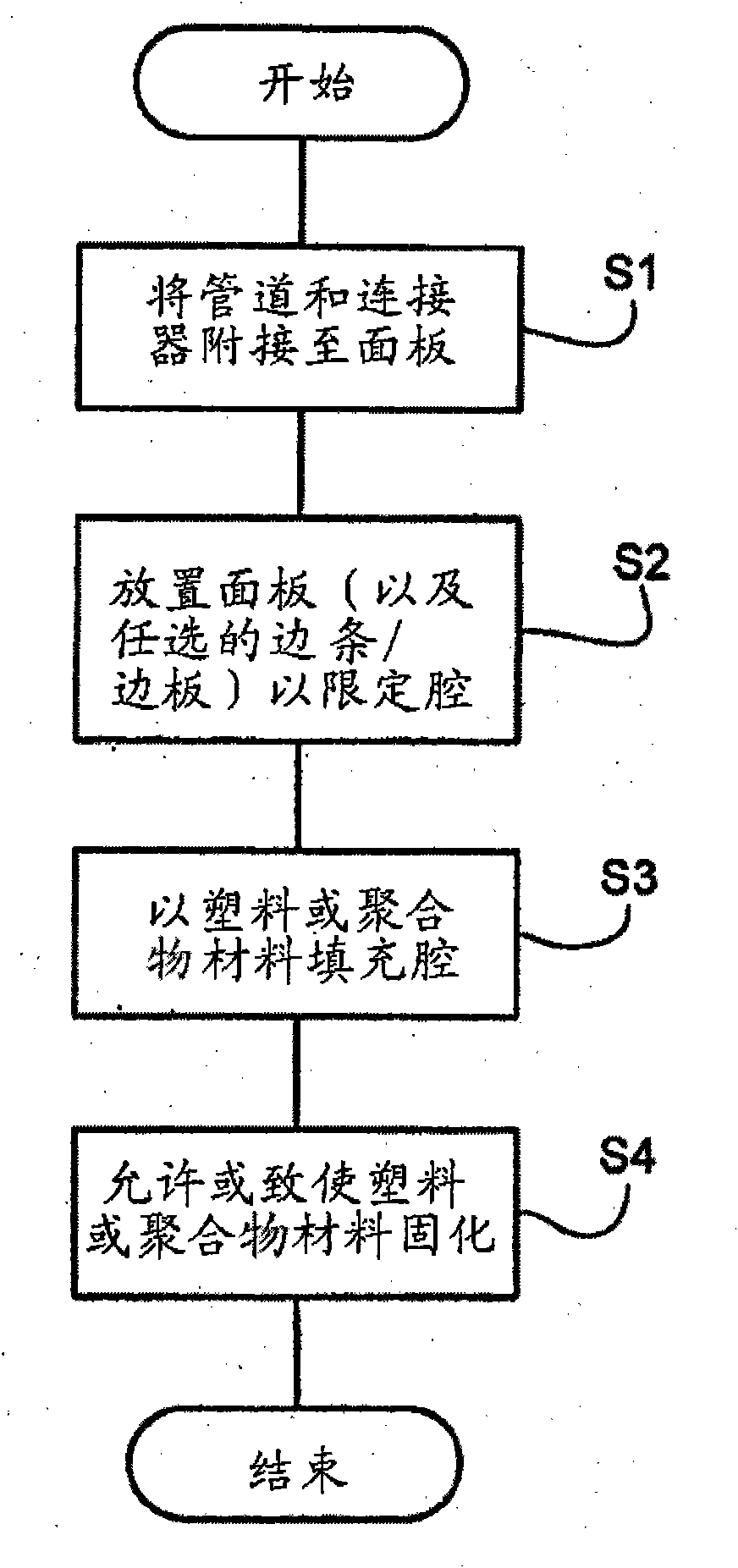

[0023] exist figure 1 The structural sandwich panel members (or panels) shown in include upper and lower outer panels (panels) 11, 12, which may be made of steel, aluminum or other metals, and have For example a thickness in the range of 0.5 to 8 mm, preferably a thickness in the range of 1 to 5 mm, more preferably a thickness in the range of 1 to 2.5 mm. Between the panels 11 , 12 there is provided a side panel, a crimped configuration, an extruded configuration or a strip 13 around its periphery to form a closed cavity. In the cavity between the panels 11 , 12 is a core 14 . The core may have a thickness in the range of 15 to 200mm; in many applications 25 to 100mm is suitable. The overall dimensions of the plate member in plan may be 1 to 5 m wide by 5 to 15 m long. Preferred dimensions are 2.5m by 10m. Plate members may be made to standard sizes or custom made to specific shapes and / or sizes.

[0024] The core 14 comprises a plastic or polymer material (preferably a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com