Diamond compact substrate

A technology of diamond composite sheet and matrix, applied in drilling equipment, earthwork drilling, drill bits, etc., can solve the problems of poor toughness, poor thermal stability and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention designs a cemented carbide substrate with both cobalt content gradient and particle size gradient, and the embedded combination of the substrate part, so as to ensure that the composite sheet has high thermal stability, wear resistance and toughness.

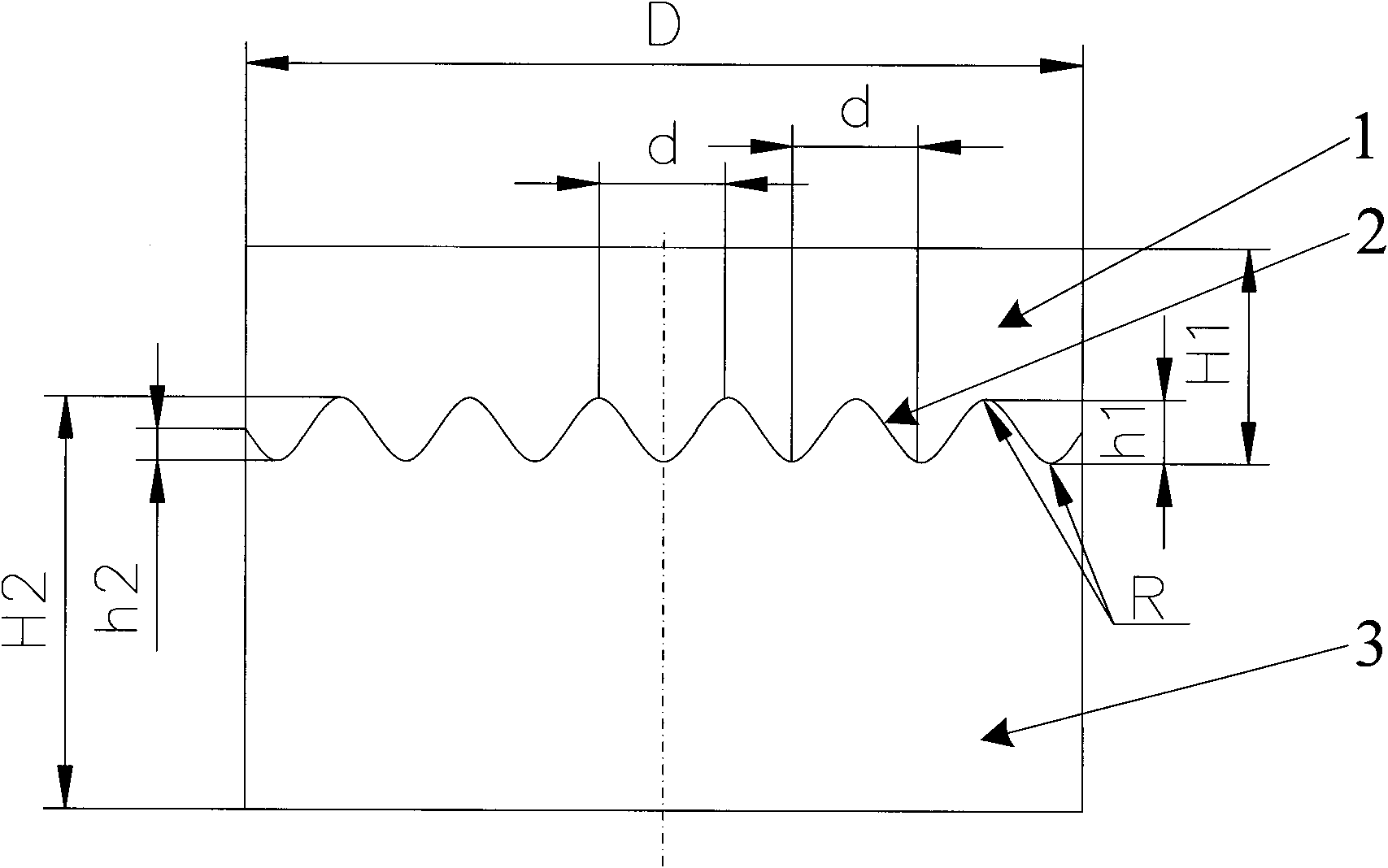

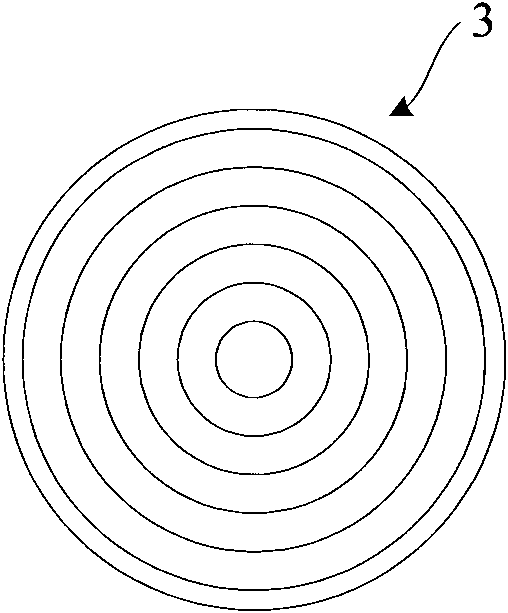

[0021] Such as Figure 1~3 As shown, the matrix of the diamond composite sheet has a double-layer structure, including the upper part 1 and the lower part 3 connected thereto.

[0022] Wherein, the composition mass percentage of the upper part 1 is: 8%-15% of cobalt, 85%-92% of tungsten carbide; the grain size of tungsten carbide is 0.5-3 μm. The mass percentages of components in the lower part 3 are: 12%-20% cobalt, 80%-88% tungsten carbide; the grain size of tungsten carbide is 2-10 μm. The diameter D of the upper part 1 and the lower part 3 of the base body is φ9-25 mm, the height H1 of the upper part is 2-5 mm, and the height H2 of the lower part is 5-15 mm. The circular wave grooves 2 are dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com