High-purity tellurium dioxide single crystal and preparation method

A technology of tellurium dioxide and single crystal, which is applied in the field of high-purity tellurium dioxide single crystal and its preparation, to achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

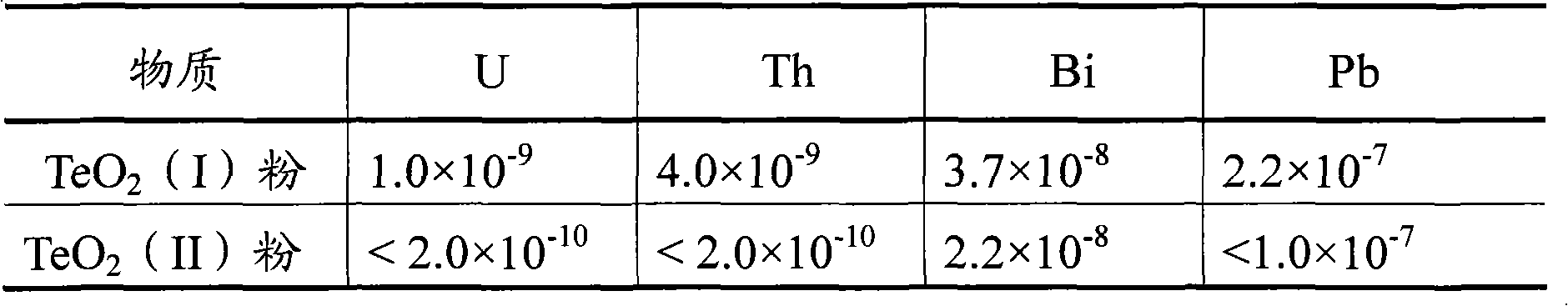

[0039] (1) TeO prepared by dissolution and neutralization 2 Powder (marked as TeO 2 (1) Powder) was packed into a platinum crucible, calcined at 680° C. for 12 hours, and then rapidly cooled to room temperature. Then put the calcined powder and the oriented seed crystal into a platinum crucible, heat up to 750° C. and keep it warm for 10 hours after sealing. Then control the heating rate to be 2°C per hour, and the crucible's descending rate to be 1.0mm per hour to grow a single crystal. After the growth is completed, the single crystal is lowered to room temperature at 30°C per hour, and then annealed at 680°C for 12 hours to complete the whole process of the first growth.

[0040] (2) Remove the surface 1-2mm of the single crystal obtained in step (1) by coarse grinding, and then dissolve the single crystal into TeCl with 37.5wt% hydrochloric acid 4 solution.

[0041] (3) then join the strong ammoniacal liquor of 28wt% to step (2) gained TeCl 4 solution, a white precipi...

Embodiment 4

[0051] (1) Commercially available TeO 2 Powder is packed in the platinum crucible, feeds oxygen and controls its flow rate to be 750ml per minute. After the powder melts, keep the temperature constant for 4 hours, then gradually lower the oriented seed crystal, adjust the surface temperature of the melt, and make the seed crystal contact the liquid surface when it is close to the solid-liquid equilibrium. After successful inoculation, the pulling rate was controlled to be 1.2 mm per hour, and the seed crystal rotation speed was 30 revolutions per minute to grow a single crystal. After the growth was completed, the single crystal was cooled down to room temperature at 60°C per hour. Finally, after 12 hours of annealing treatment at 680° C., the whole process of the first growth is completed.

[0052] (2) Remove 0.5-0.8mm of the surface of the single crystal obtained in step (1) by coarse grinding, and then dissolve the single crystal into TeCl with 37.5wt% hydrochloric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com