Hollow carbon fiber felt epoxy resin composite material and preparation method thereof

A technology of felt epoxy resin and composite materials, which is applied in the field of carbon fiber epoxy resin composite materials and its preparation, can solve the problems of high density and difficulty in three-dimensional weaving of carbon fibers, and achieve increased payload, good degree of graphitization, and improved bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Embodiment 1: The hollow carbon fiber felt epoxy resin composite material in this embodiment is made of hollow carbon fiber felt and epoxy resin glue; wherein the hollow carbon fiber felt is made of urea and carbon powder in a mass ratio of 50 to 150:1 Made; epoxy resin glue is composed of bisphenol A type epoxy resin, acetone and diethylene triamine, wherein the mass ratio of bisphenol A type epoxy resin to acetone is 100:5~10, bisphenol A type The mass ratio of epoxy resin to diethylenetriamine is 100:8-12.

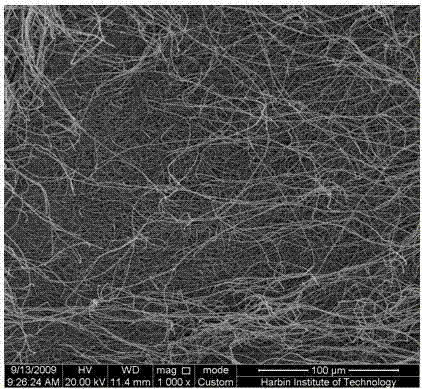

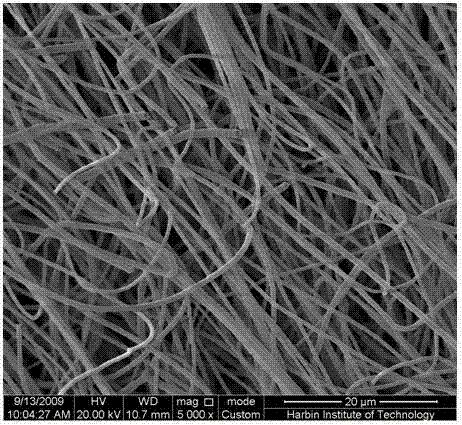

[0009] The hollow carbon fiber felt of this embodiment is synthesized by chemical vapor growth method in a closed static system without any catalyst under the action of air pressure. The hollow carbon fiber felt has a tube diameter of 1 μm, a wall thickness of 5 nm to 10 nm, and a length It reaches centimeter level and is self-woven into a felt structure with a thickness of 5mm to 10mm. The hollow carbon fiber felt is synthesized in situ at low temperature, and ...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that the hollow carbon fiber felt is made of urea and carbon powder at a mass ratio of 60-140:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the hollow carbon fiber felt is made of urea and carbon powder at a mass ratio of 100:1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com