High temperature-resistant and acid corrosion-resistant stainless steel and preparation method thereof

A technology of acid corrosion resistance and stainless steel, applied in the field of stainless steel, can solve the problem that the corrosion rate cannot meet the requirements of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

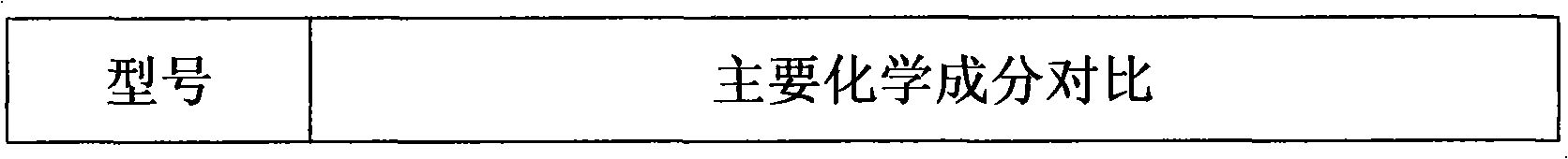

Image

Examples

Embodiment 1

[0030] Use a non-vacuum intermediate frequency induction furnace to smelt stainless steel, and use sand molds or metal molds to cast. During the smelting process, the temperature is gradually raised to about 1600°C for 2.5 hours. After casting, the castings need to be kept in the cavity for 2 days, and samples are taken for testing. The composition of each element of stainless steel is shown in Table 2. Its acid corrosion resistance in 98% concentrated sulfuric acid and 93% concentrated sulfuric acid is shown in Table 3 and Table 4.

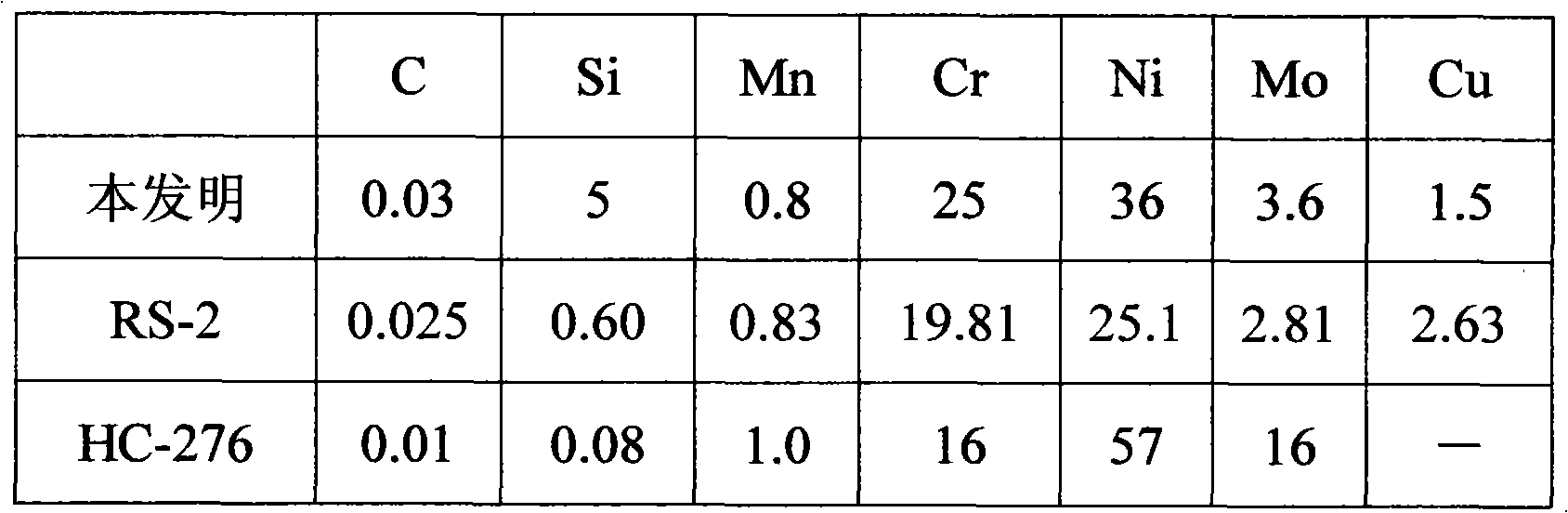

[0031] The composition of each element in the stainless steel of the present invention in table 2

[0032]

[0033] Table 3 Corrosion resistance of different types of stainless steel in 98% concentrated sulfuric acid

[0034]

[0035]

[0036] Table 4 Corrosion resistance of different types of stainless steel in 93% concentrated sulfuric acid

[0037]

[0038] It can be seen from the table that the corrosion resistance of the presen...

Embodiment 2

[0040] Use a non-vacuum intermediate frequency induction furnace to smelt stainless steel, and use sand or metal molds to cast. During the smelting process, the temperature is gradually raised to about 1650°C for 3 hours. After casting, the casting needs to be kept in the cavity for 3 days, and the sample piece is tested. The composition of each element of stainless steel is shown in Table 5. Its acid corrosion resistance in 60% concentrated sulfuric acid is shown in Table 6.

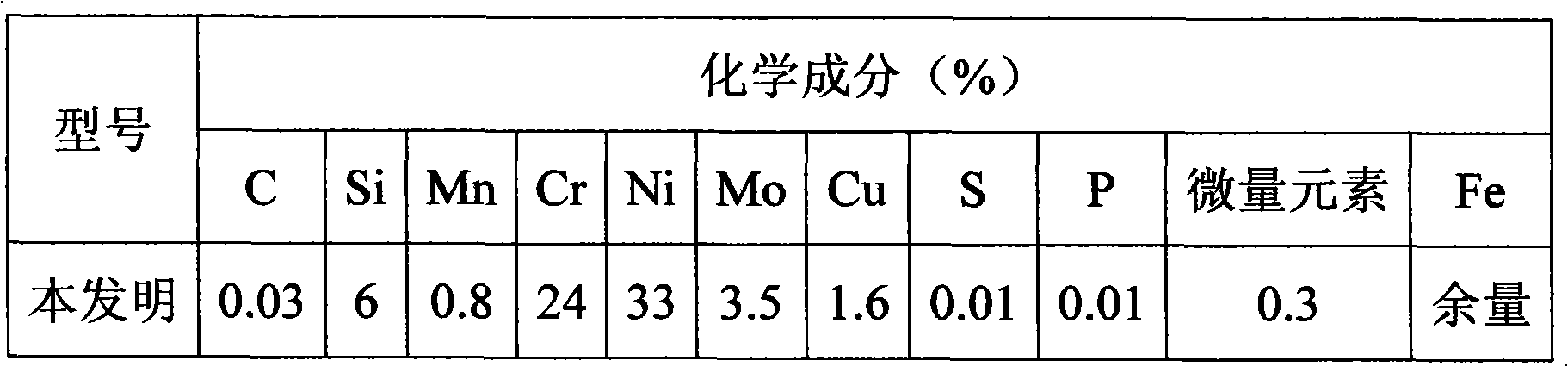

[0041] The composition of each element in the stainless steel of the present invention in table 5

[0042]

[0043] Table 6 Corrosion resistance of different types of stainless steel in 60% concentrated sulfuric acid

[0044]

[0045]

[0046] It can be seen from the table that the corrosion resistance of the present invention is superior to the level of related products at home and abroad, and can be applied in the medium of 60% concentrated sulfuric acid.

Embodiment 3

[0048] Stainless steel is smelted in a non-vacuum intermediate frequency induction furnace, and cast with sand or metal molds. During the smelting process, the temperature is gradually raised to about 1700°C for 2.8 hours. After casting, the castings need to be kept in the cavity for 4 days, and samples are taken for testing. The composition of each element of stainless steel is shown in Table 7. Its acid corrosion resistance in 60% concentrated sulfuric acid is shown in Table 8.

[0049] The composition of each element in the stainless steel of the present invention in table 7

[0050]

[0051]Table 8 Corrosion resistance of different types of stainless steel in 60% concentrated sulfuric acid

[0052]

[0053] It can be seen from the table that the corrosion resistance of the present invention is superior to the level of related products at home and abroad, and can be applied in the medium of 60% concentrated sulfuric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com