Reciprocating type plant grid system and application thereof

A plant grid, reciprocating technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of large land occupation, obstruction of smooth water flow, and inability to adapt to changeable farmland ditches Water depth and other issues, to achieve the effect of small footprint, improved removal effect, easy cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

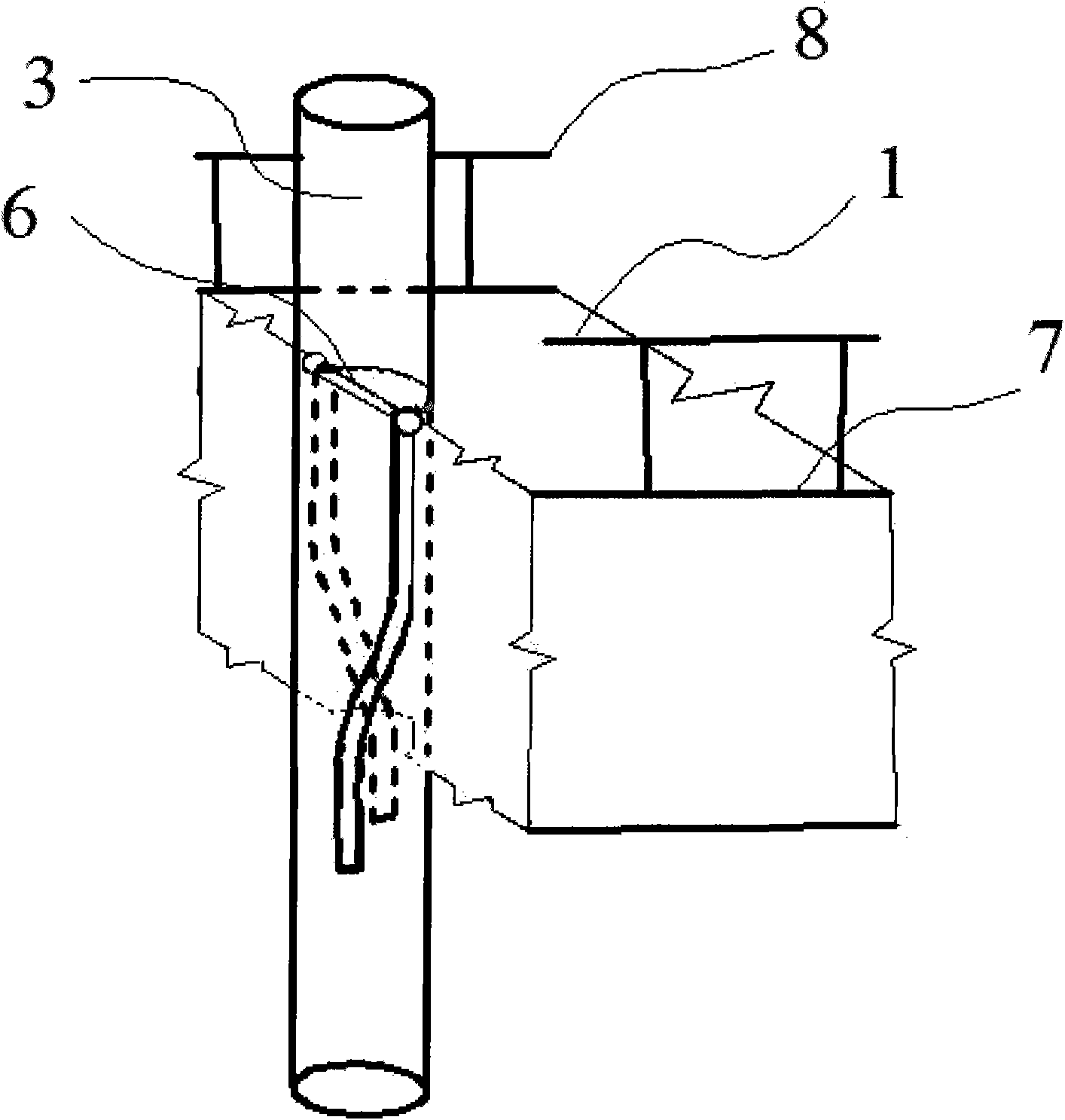

[0033] To build a reciprocating plant grid system, see figure 1 , 6 ; Take the straight pentagonal prism as the shape of the plant grid body as an example to illustrate the specific implementation; the straight pentagonal prism A 1 A 2 A 3 A 4 A 5 -A 1 'A 2 'A 3 'A 4 'A 5 ’, prism side A 3 A 4 B 4 B 3 The included angle with the cross section of the ditch is θ, and the edge A 3 A 4 (A 3 'A 4 ), edge A 4 A5 (A 4 'A 5 ’) are respectively l and b, and the lengths of the other three groups of pentagonal prisms can be described by l, b and θ, Use bamboo or wood to build the main body of the plant grid frame. The outer diameter of bamboo or wood strips is controlled at 6cm. The parts are connected with galvanized iron wires and iron nails. In use, ceramsite and zeolite are placed on the grid made of coconut palm fiber. In the drawer, there are ceramsite and layer zeolite layers from bottom to top, and corresponding plants are planted on the top, and then a ...

Embodiment 2

[0040] A water tank is designed in the interior, and the characteristics of the water tank are length × width × height = 120cm × 50cm × 80cm, and the water tank experiment is carried out. The constructed elliptical cylindrical reciprocating plant grid ( Figure 7 ), made of polytetrafluoroethylene buckets after punching and fixing, the volume of the grid body is about 0.0624m 3 The height of grid body is 45cm; The laying thickness of ceramsite is 22cm; The thickness of zeolite laying is 3.5cm; Ceramsite; The self weight of plant grid area is greater than or equal to the buoyancy in sewage; 100 plants / m 2 The fixed connection shaft is constructed with a PVC pipe, its outer diameter is 5cm, and its length is 80cm. The vertical distance of the groove is 10cm. The bottom and side surfaces of the plant grid frame are constructed of a mesh structure with an aperture of 0.5-1.0 cm, such as galvanized barbed wire, rattan woven net or bamboo woven net. The concentrations of the ind...

Embodiment 3

[0042] A water tank is designed in the interior, and the characteristics of the water tank are length × width × height = 120cm × 50cm × 80cm, and the water tank experiment is carried out. The constructed vase-shaped reciprocating plant grid ( Figure 8 ), the volume of the grid body is about 0.056m 3 The height of the grid body is 50cm; the laying thickness of ceramsite is 25cm; the laying thickness of zeolite is 5cm; the coconut palm fiber mat is 10cm; The grid frame is made of Teflon material and plexiglass, and the outer diameter of the material used for the frame is 2 to 3 cm; the balance of the grid body is adjusted with an empty Teflon bottle; water spinach is selected as the plant, and the planting density is 50 Plant / m 2 The fixed connection shaft is constructed with a PVC pipe, its outer diameter is 5cm, and its length is 80cm. The vertical distance of the groove is 10cm. The bottom and sides of the plant entry grid frame are constructed of a mesh structure with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com