High-peeling strength polyethylene conveying belt and manufacturing method thereof

A manufacturing method, polyethylene technology, applied in the direction of conveyors, belts, transportation and packaging, etc., can solve the problem of not breaking through the category of physical combination, and achieve the effect of improving compatibility, large peel strength, and increased peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

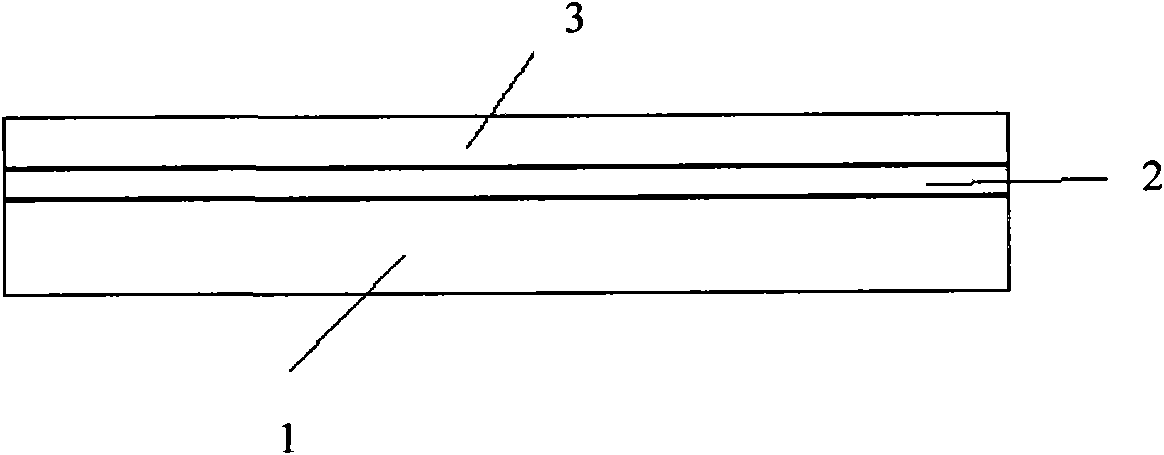

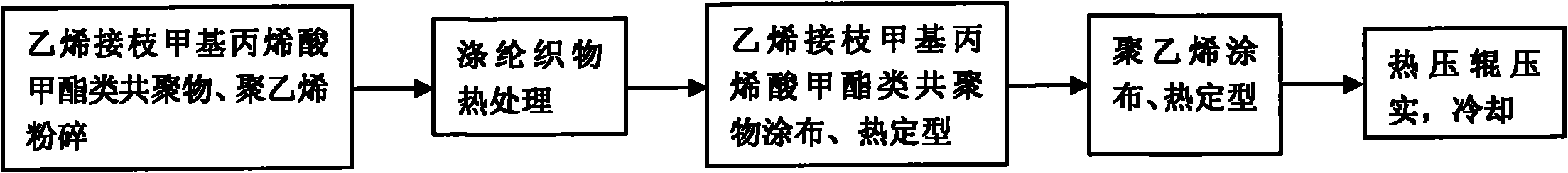

[0024] see figure 1 It is the layered structure schematic diagram of polyethylene conveyor belt of the present invention and figure 2 Shown in the process flow diagram of the present invention, for the manufacture method of the high peel strength polyethylene conveyer belt described in claim 1, comprises the following steps:

[0025] Step 1: Graft ethylene-grafted methyl methacrylate copolymer (modified polyethylene, melt index is 5g / 10min~10g / 10min, methyl methacrylate content is 10%-30%) at -35~ Crush at -40°C to make a powder, with a particle size range of 10 μm to 20 μm; crush the polyethylene, cryogenically crush the polyethylene into a powder in a liquid nitrogen environment, and make it into a powder, with a particle size range of 10 μm ~20μm;

[0026] Step 2: Polyester fabric 1 is heat-treated at 170°C to 190°C;

[0027] Step 3: Apply ethylene-grafted methyl methacrylate copolymer powder on the surface of polyester fabric 1, and heat-setting at 170-190°C to make et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com