Vacuum thermal baffle packaging film and preparation method thereof

A vacuum heat insulation board and packaging film technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of affecting the heat insulation effect of finished VIP boards, affecting the appearance of VIP boards, and difficult production processes, etc., to achieve good physical Good mechanical properties, peel strength, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

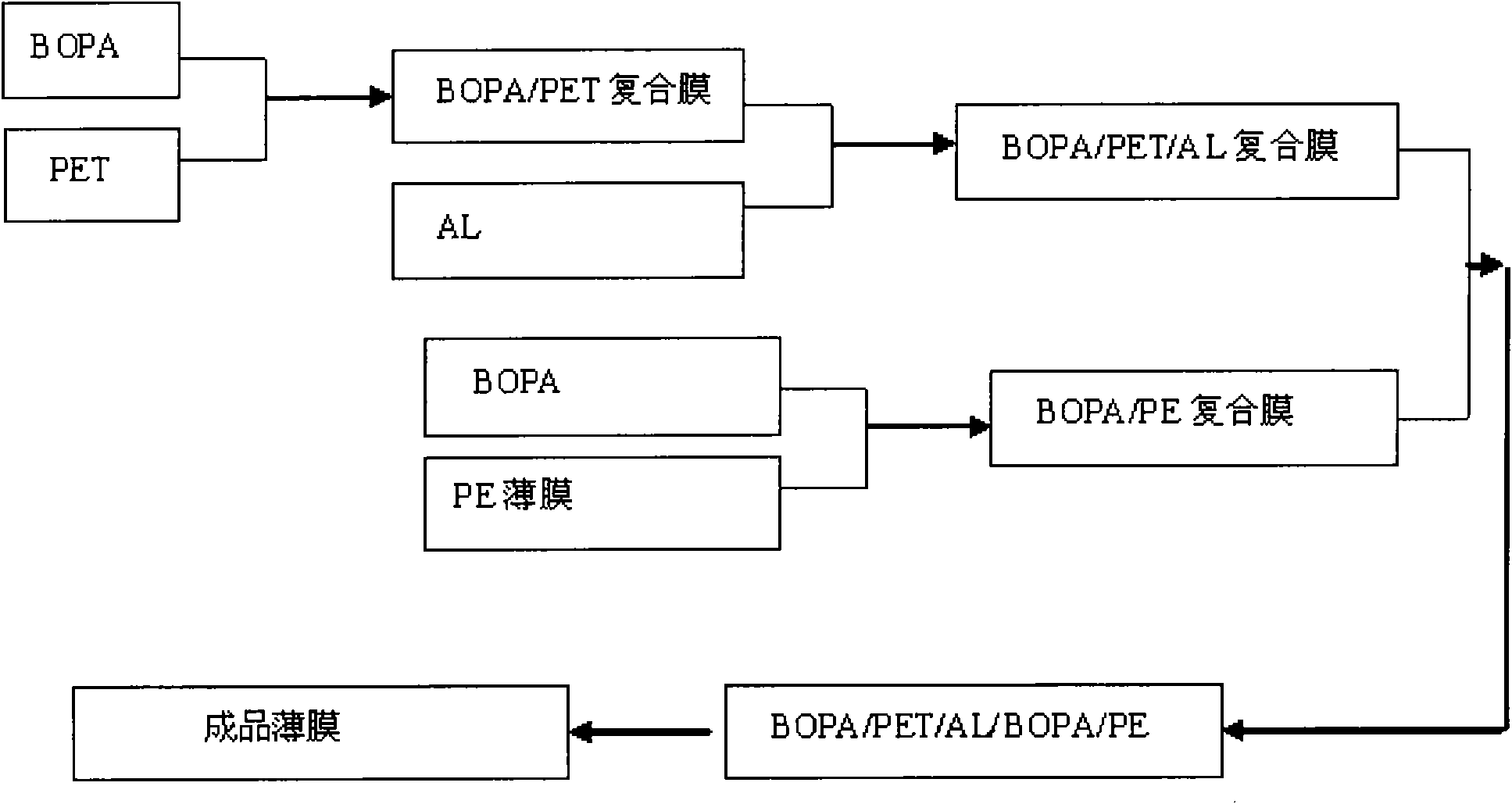

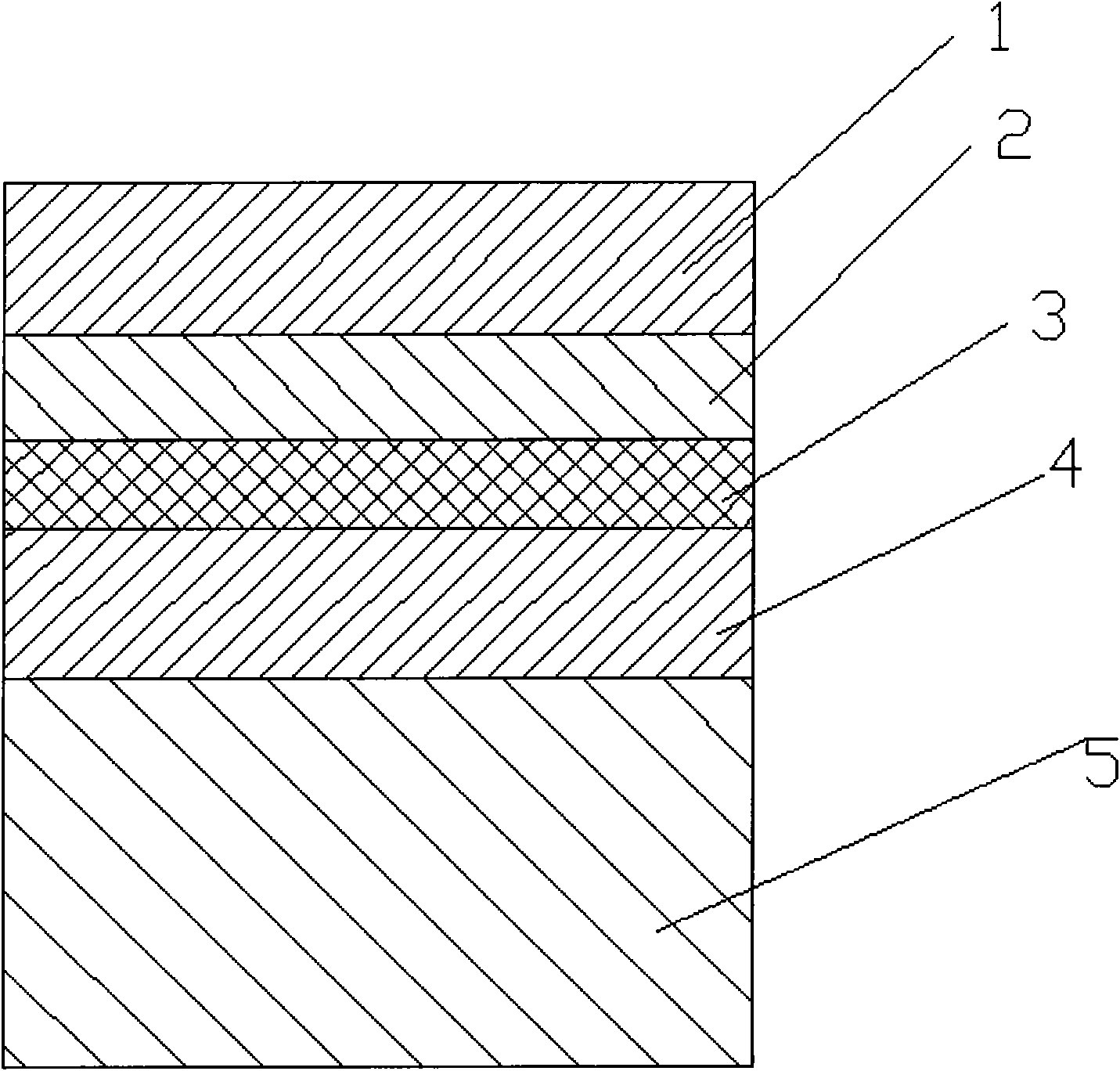

[0037] Vacuum insulation panel packaging films such as figure 1 Shown: its production process is as follows:

[0038] a. Printing process: Printing on biaxially stretched nylon film at 20-30°C;

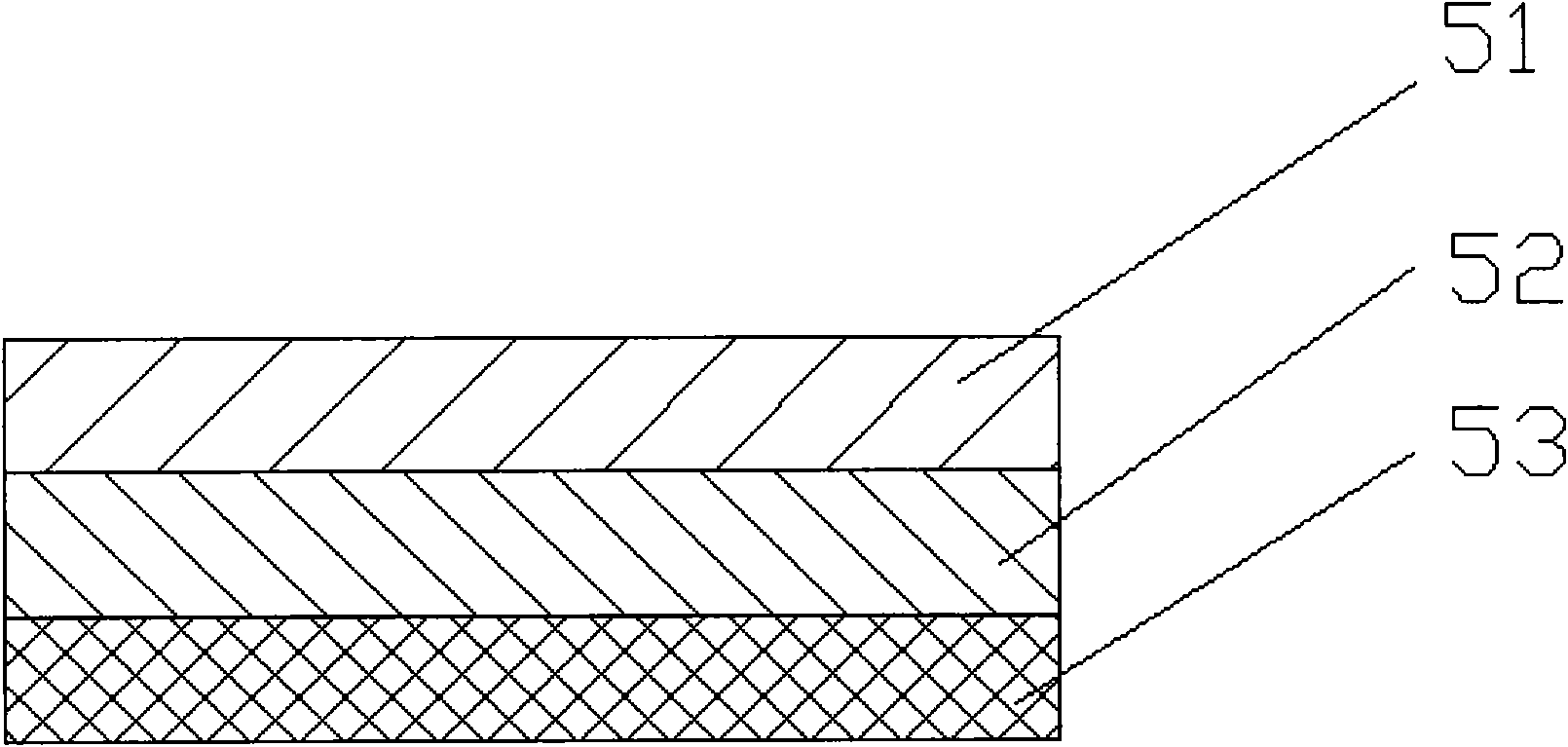

[0039] b. The preparation process of composite polyethylene: each layer of polyethylene resin is placed in its own barrel and extruded according to a specific addition ratio to form a composite polyethylene film; image 3 As shown: the composite polyethylene layer is sequentially composed of a composite outer layer 51, a core layer 52, and a heat-sealed inner layer 53 from outside to inside;

[0040] c. The first dry compounding process: compound the biaxially stretched nylon film and the polyethylene terephthalate film on which the pattern text has been printed through a dry compound machine, and then compound the biaxially stretched nylon film / Dry lamination of polyethylene terephthalate film and aluminum foil to form biaxially stretched nylon / polyethylene terephthalate / aluminum...

Embodiment 2

[0057] Except in b, the preparation process of composite polyethylene.

[0058] Composite outer layer: 45% m-LLDPE DOW5100 (manufactured by Dow Chemical Company);

[0059] 45% MDPE 2038.68G (manufactured by Dow Chemical Company);

[0060] 10% LDPE150BW (produced by Exxon Mobil);

[0061] Core layer: 60% HDPE HTA108 (produced by Exxon Mobil);

[0062] 40% m-LLDPE 1018FA (produced by Exxon Mobil);

[0063] Layer C: 30% LDPE 150BW (produced by Exxon Mobil);

[0064] 70% m-LLDPE PL1881G (manufactured by Dow Chemical Company);

[0065] The composite polyethylene made is the same as Example 1 except for ±5% limit deviation.

Embodiment 3

[0067] Except in b, the preparation process of composite polyethylene.

[0068] Composite outer layer: 30% m-LLDPE DOW5100 (manufactured by Dow Chemical Company);

[0069] 50% MDPE 2038.68G (manufactured by Dow Chemical Company);

[0070] 20% LDPE150BW (produced by Exxon Mobil);

[0071] Core layer: 50% HDPE HTA108 (produced by Exxon Mobil);

[0072] 50% m-LLDPE 1018FA (produced by Exxon Mobil);

[0073] Layer C: 40% LDPE 150BW (produced by Exxon Mobil);

[0074] 60% m-LLDPE PL1881G (manufactured by Dow Chemical Company);

[0075] Made composite polyethylene ± 5% limit deviation; the rest is the same as embodiment 1.

[0076] The main technical index of embodiment 1-3 is as follows:

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com