Ultrasonic flotation method and device and application thereof

A flotation device and ultrasonic technology, used in flotation, solid separation and other directions, can solve the problems of low target ore recovery rate and low concentrate grade, and achieve the effects of saving labor costs, reducing overall energy consumption, and easy automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

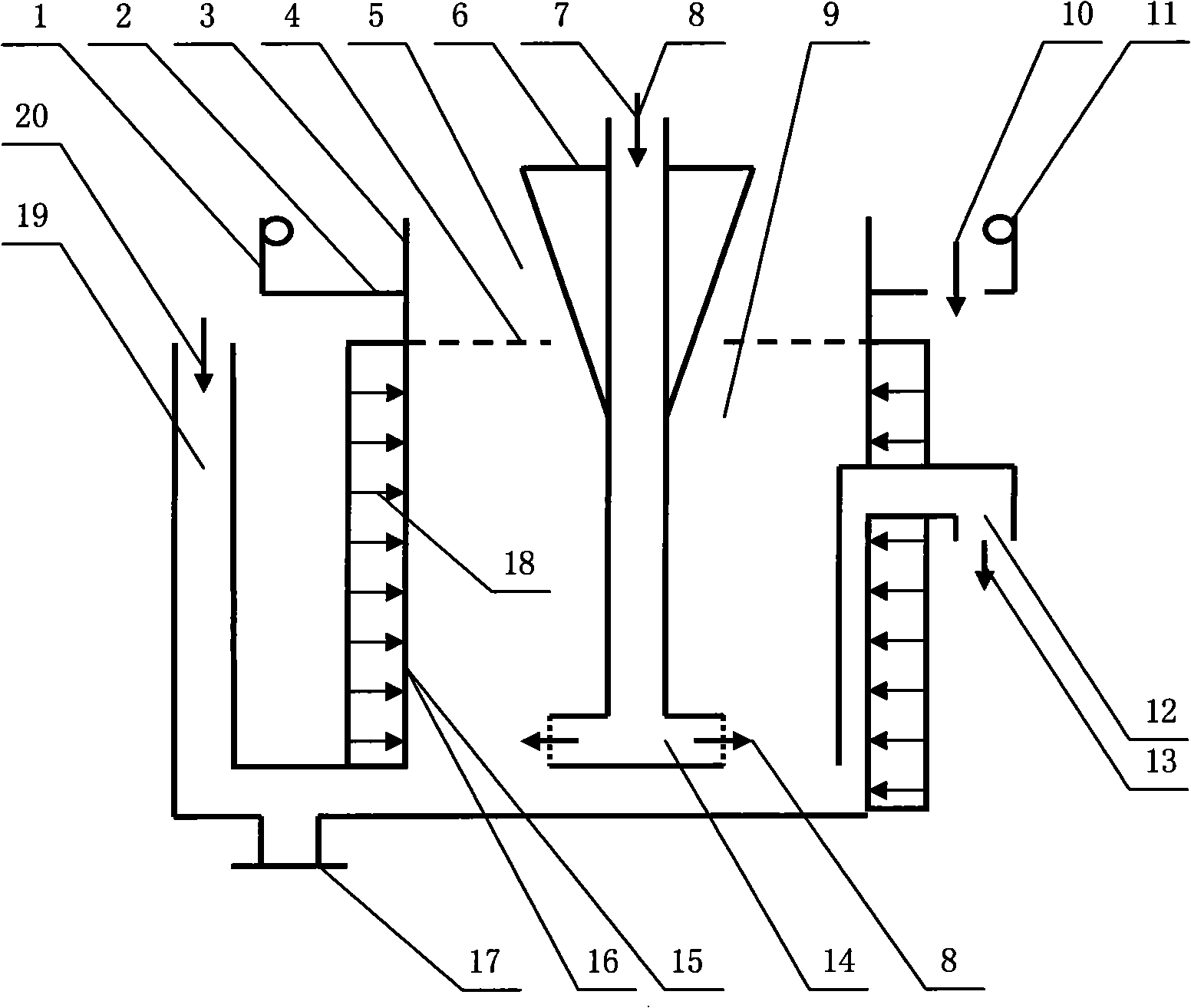

[0038] Example 1: Ultrasonic flotation device that emits ultrasonic waves from the side wall of the flotation tank

[0039] figure 1 It is an ultrasonic flotation device that emits ultrasonic waves from the side wall of the flotation tank. The ultrasonic source frequency of the ultrasonic device 15 is 20kHz, and the sound intensity is 0.5-4w / cm 2 . The ultrasonic emitting surface 16 of the ultrasonic device is submerged and arranged below the liquid surface 4 of the ore slurry. The sound intensity of the ultrasonic source, from the bottom of the flotation tank body 3 to the vertical interval of the slurry liquid level, is set in a way that tends to weaken. That is, the sound intensity of the ultrasonic source at the bottom of the flotation cell is 4w / cm 2 ; When approaching the liquid surface of the slurry, the sound intensity of the ultrasonic source is 0.5w / cm 2 . The ultrasonic source is set in such a way that the sound intensity tends to be weakened, aiming at contro...

Embodiment 2

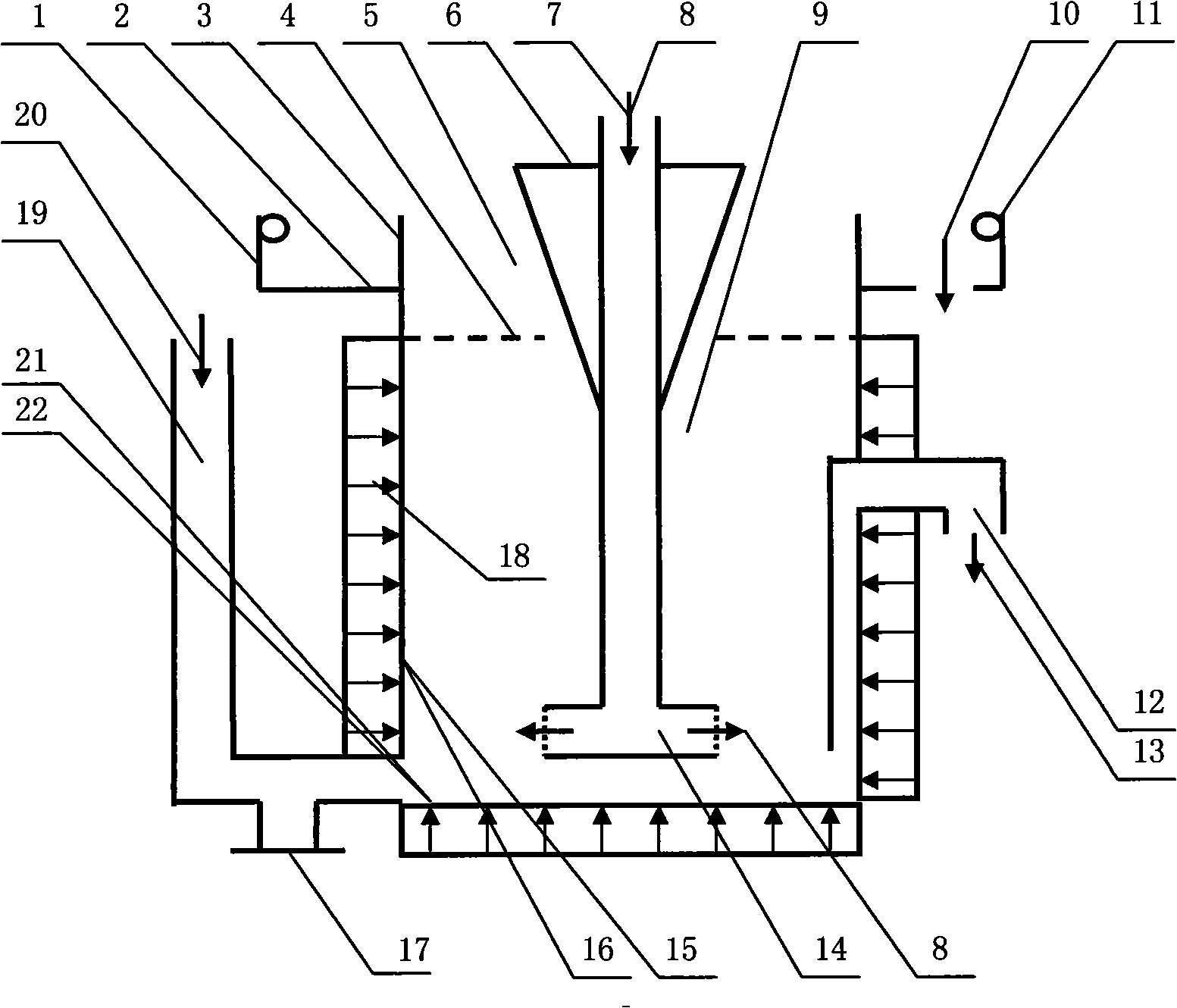

[0042] Embodiment 2: an ultrasonic flotation device that emits ultrasonic waves synchronously from the side wall and bottom of the flotation tank.

[0043] figure 2 It is an ultrasonic flotation device that emits ultrasonic waves synchronously from the side wall and bottom of the flotation tank. The ultrasonic source frequency of the ultrasonic device 15 is 20kHz, and the sound intensity is 2w / cm 2 ; The ultrasonic source frequency of the ultrasonic device 21 is 20kHz, and the sound intensity is 4w / cm 2 . The method of synchronously emitting ultrasonic waves from the side wall and bottom of the flotation tank body 3 aims to increase the intensity of the ultrasonic cavitation effect of ultrasonic energy on the pulp.

[0044] the experiment shows, figure 2 When the ultrasonic flotation device shown is used for flotation of refractory low-grade gold-bearing minerals, the recovery rate of gold-bearing ore is increased by more than 20% compared with conventional flotation dev...

Embodiment 3

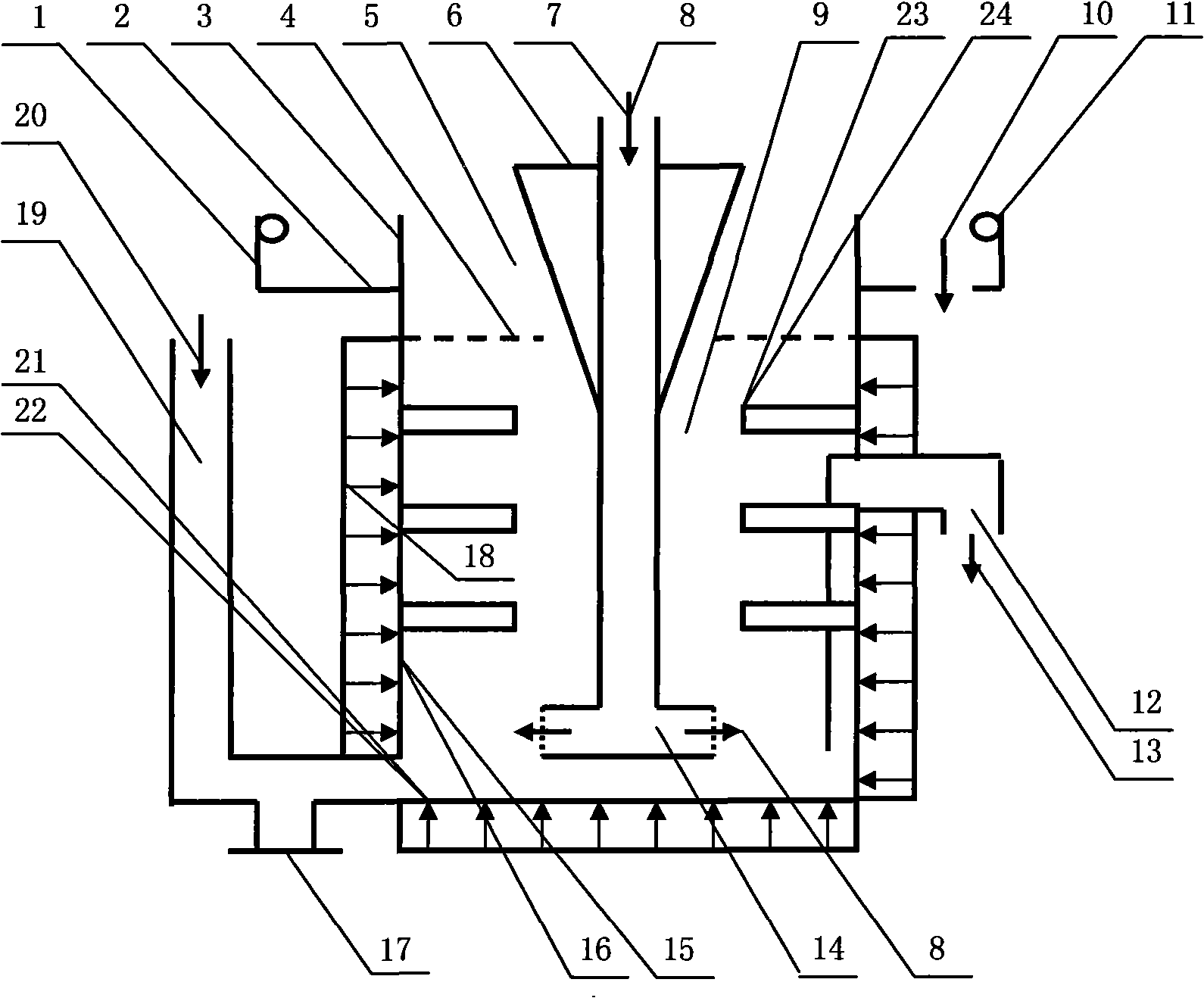

[0046] Embodiment 3: an ultrasonic flotation device that emits ultrasonic waves synchronously from the side wall, bottom and center of the flotation tank.

[0047] image 3 The ultrasonic flotation device shown is in figure 2 More than one ultrasonic device 23 is added in the ultrasonic flotation device shown. The ultrasonic source frequency of the ultrasonic device 23 is 20-128kHz, and the sound intensity is 50-200w / cm 2 ; Its ultrasonic emitting surface 24 adopts a set curved surface to transmit ultrasonic energy to the pulp 9 . This ultrasonic flotation device is mainly used for large-scale flotation production process or ultrasonic flotation of refractory minerals. When the diameter of the ultrasonic flotation device is greater than 2 meters, due to the attenuation and transmission of ultrasonic energy in the pulp, the pulp in the center of the flotation tank is difficult to receive ultrasonic energy from the side wall or bottom of the flotation tank. At this time, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com