Catalyst used for preparing methane by using synthesis gas and preparation method thereof

A catalyst and synthesis gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. problem, to achieve the effect of good activity and selectivity, large specific surface area and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 53.6g of aluminum nitrate nonahydrate, 7.8g of nickel nitrate hexahydrate, 2.56g of magnesium nitrate, 0.2g of lanthanum nitrate, and 0.127g of sodium nitrate and dissolve them in 50ml of deionized water, stir the solution and heat to 60°C. If there are some insoluble particles, use a funnel to filter to prevent particle aggregation and nucleation during co-precipitation. Weigh 22.6g of urea, raise the temperature of the solution to 90°C, add 1ml of polyethylene glycol (PEG-200) as a dispersant, gradually add the required urea into the solution, and stir vigorously. Urea decomposes into ammonia and CO at high temperature 2 , the color of the solution gradually changed from light green to dark green. Check the pH of the solution, if the pH drops to around 6.5, the precipitation is complete.

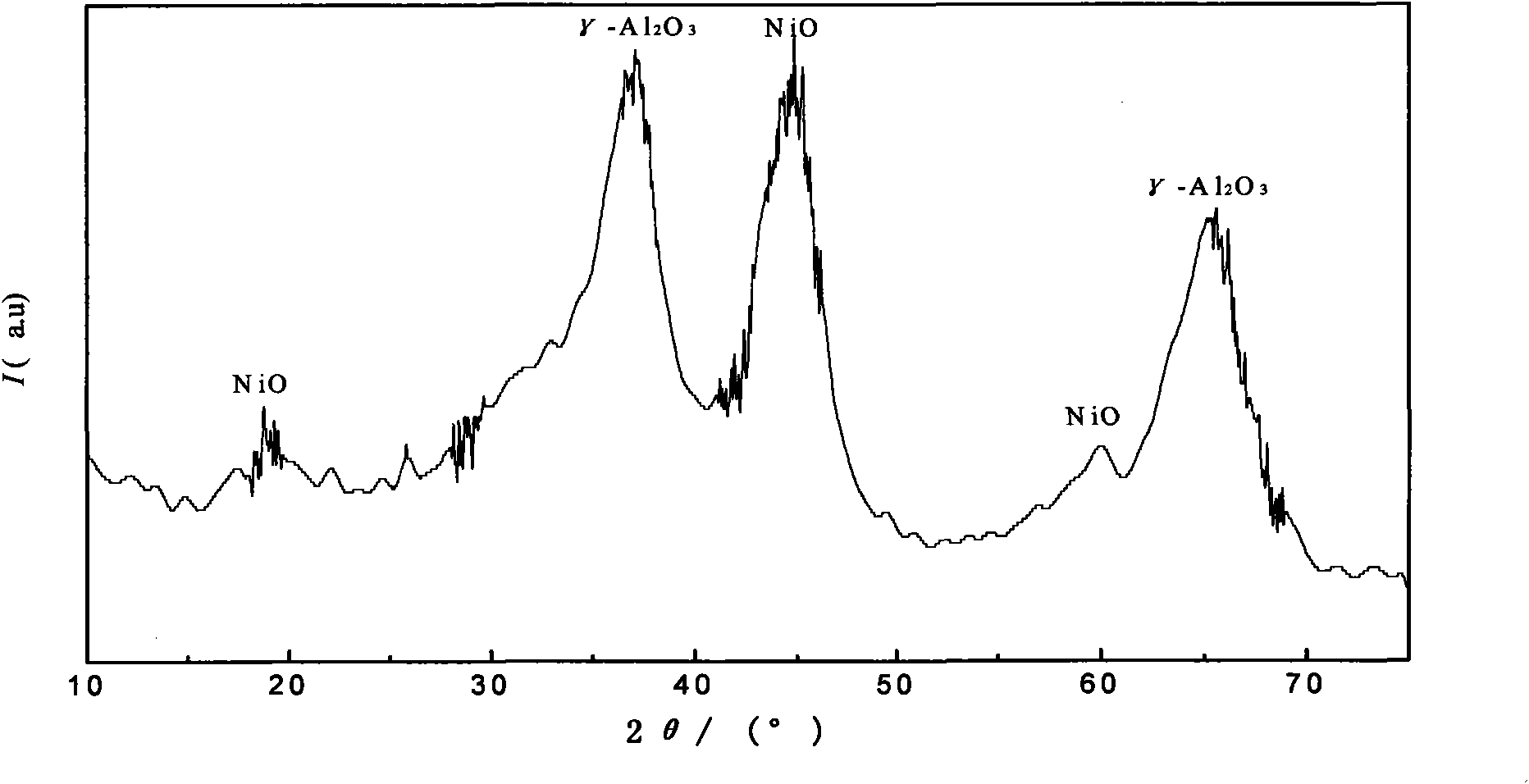

[0024] Filter the remaining solution, place it in a desiccator at 120°C for 5 hours, then transfer it to a muffle furnace for calcination, the calcination temperature is 500...

Embodiment 2

[0027] Weigh 53.6g Al(NO 3 ) 3 9H 2 O, 7.8g Ni(NO 3 ) 2·6H 2 O, 2.56g Mg(NO 3 ) 2 ·6H 2 O, 0.2g La(NO 3 ) 3 ·6H 2 O, 0.102g Sr(NO 3 ) 2 Dissolve in 50 ml of deionized water, stir the solution and heat to 60°C. Weigh 14.56g NH 4 HCO 3 solid, the temperature of the solution was raised to 90° C., 1 ml of polyethylene glycol (PEG-200) was added as a dispersant, and the weighed ammonium bicarbonate was gradually added to the solution and stirred vigorously. As the ammonium bicarbonate is decomposed by heat, the color of the solution gradually changes to dark green. When the pH value of the solution drops to about 6.5, the precipitation is basically complete. Filter off the remaining solution, dry in a desiccator at 120°C for 5 hours, then transfer to a muffle furnace for calcination, the calcination temperature is 500°C and maintain for 4 hours, after calcination, crush the catalyst particles and filter with a 200-mesh sieve. A methanation catalyst is obtained. Th...

Embodiment 3

[0030] Nanoparticles are prepared by the water-in-oil (W / O) microemulsion method. The surface of the particles is coated with a layer of surfactant, which makes it difficult for the particles to agglomerate, and the size of the particles can be controlled by selecting different surfactant molecules. Prepare the microemulsion of water phase-SDS-isopropanol-cyclohexane according to the principle of microemulsion method, wherein the water phase is 51.4gAl(NO 3 ) 3 9H 2 O, 5.85g Ni(NO 3 ) 2 ·6H 2 O, 3.88g Co(NO 3 ) 2 ·6H 2 O mixed ionic solution. Wherein SDS is a surfactant, isopropanol is a co-surfactant, and cyclohexane is an organic phase. In addition, 25g of NaOH was weighed and dissolved in deionized water, and the NaOH solution was slowly added dropwise into the microemulsion in the air while vigorously stirring, and flocculent precipitates were formed. Continue to stir vigorously for 30 minutes after the dropwise addition, age for 1 hour, then centrifuge to separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com