Low-temperature electrolyte of lithium iron phosphate power battery and preparation method thereof

A power battery, lithium iron phosphate technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems that limit the application of lithium iron phosphate power battery, electric bicycles, electric vehicles, etc., and facilitate the migration of lithium ions , Conducive to effective dissolution, suitable for low temperature discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The low-temperature electrolyte of the lithium iron phosphate power battery of the present invention selects 27% ethylene carbonate (EC), 25% dimethyl carbonate (DMC), 25% methyl acetate (MA), and 20% ethylene carbonate (EC) respectively by weight ratio. Propylene carbonate (PC), fully mixed in a glove box with a humidity of less than 1%, was prepared as an electrolyte solvent, and then added additives: 1% polystyrene (PS), 2% vinylene carbonate (VC), Then slowly add electrolyte lithium salt LiPF6 with a total amount of 1.2 mol / L, completely dissolve, and let it stand for 30 hours to obtain the low-temperature electrolyte for lithium iron phosphate power battery of the present invention.

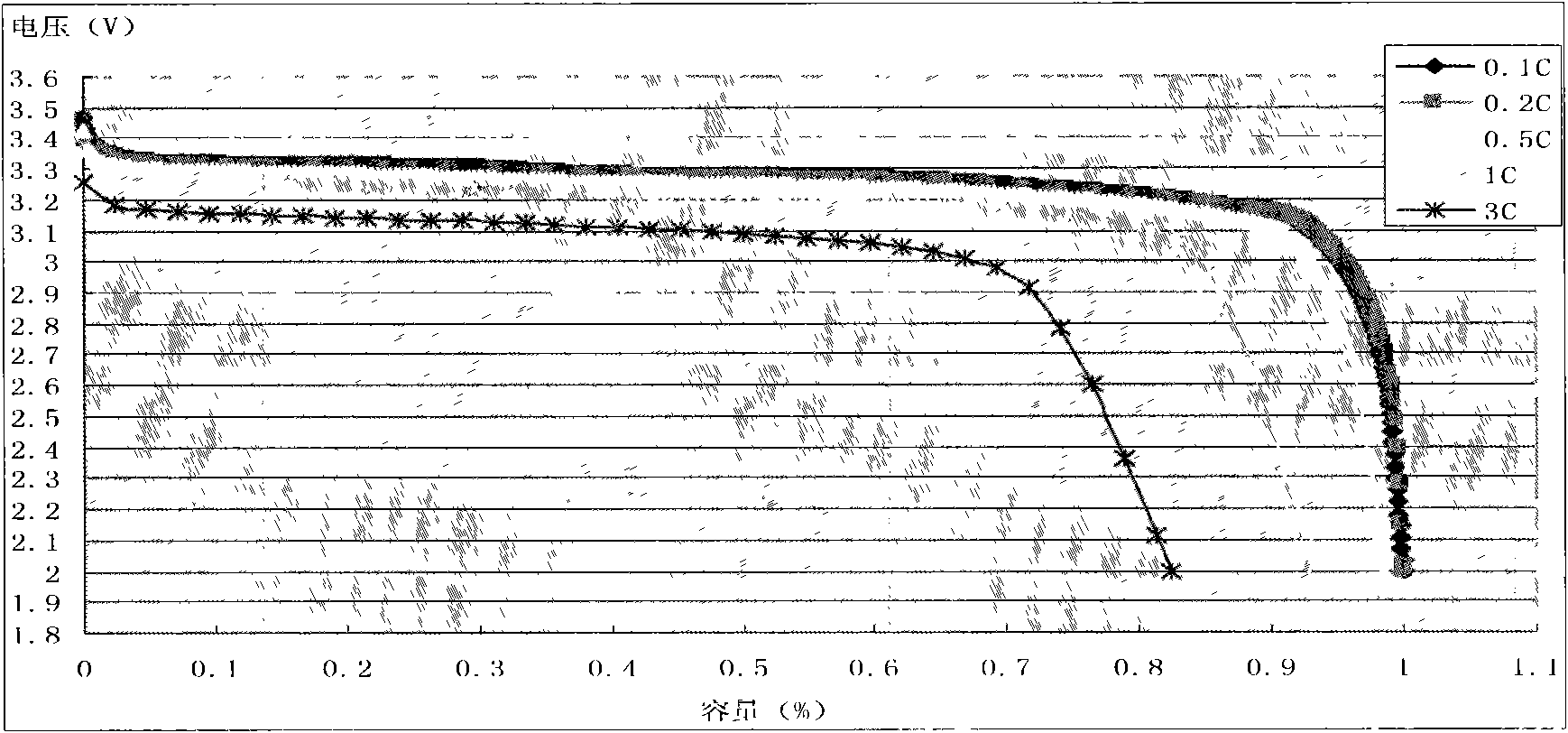

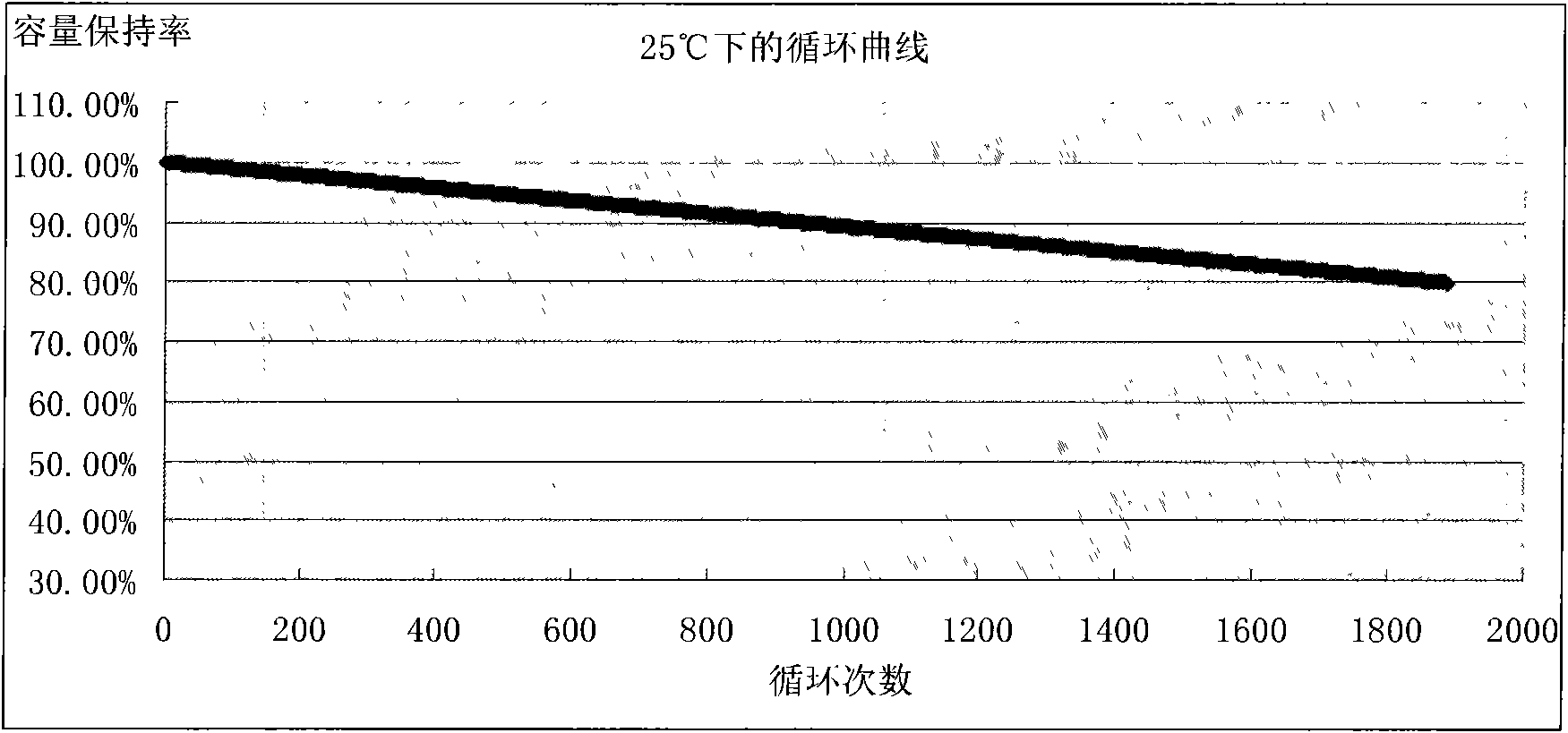

[0026] Inject the obtained low-temperature electrolyte of the lithium iron phosphate power battery into a soft-packed lithium iron phosphate power battery of the model F10-7568270, with a capacity of 10Ah and a voltage of 3.2V; after testing, the specific energy reaches 123W / g, and it ...

Embodiment 2

[0028] The low-temperature electrolyte of the lithium iron phosphate power battery of the present invention selects respectively 20% ethylene carbonate (EC), 35% diethyl carbonate (DEC), 30% methyl acetate (MA), 11% Propylene carbonate (PC), fully mixed in a glove box with a humidity of less than 1%, was prepared as an electrolyte solvent, and then added additives: 1.5% polystyrene (PS), 1.5% vinylene carbonate (VC), 1% hydroxycarboxylic acid, and then slowly add a total amount of 1.2mol / L electrolyte lithium salt LiPF6, after completely dissolving, let it stand for 40 hours to obtain the low-temperature electrolyte for lithium iron phosphate power battery of the present invention.

[0029] Inject the obtained low-temperature electrolyte of the lithium iron phosphate power battery into a soft-packed lithium iron phosphate power battery of the model F10-7568270, with a capacity of 10Ah and a voltage of 3.2V; after testing, the specific energy reaches 123W / g, and it can be discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com