Oil-immersed water-cooled high-power electric and electronic capacitor

A technology for power electronics and capacitors, applied in the field of oil-immersed high-power power electronic capacitors, can solve the problems of capacitor overcurrent capability limitation, personal and property loss, film shrinkage and deformation, etc. , the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

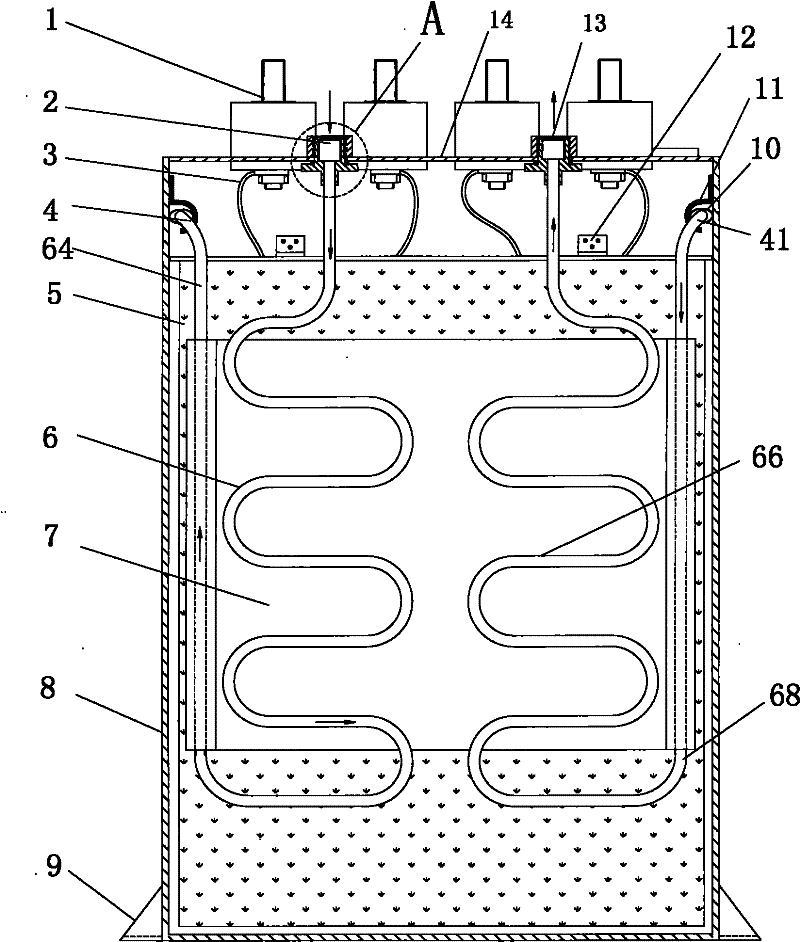

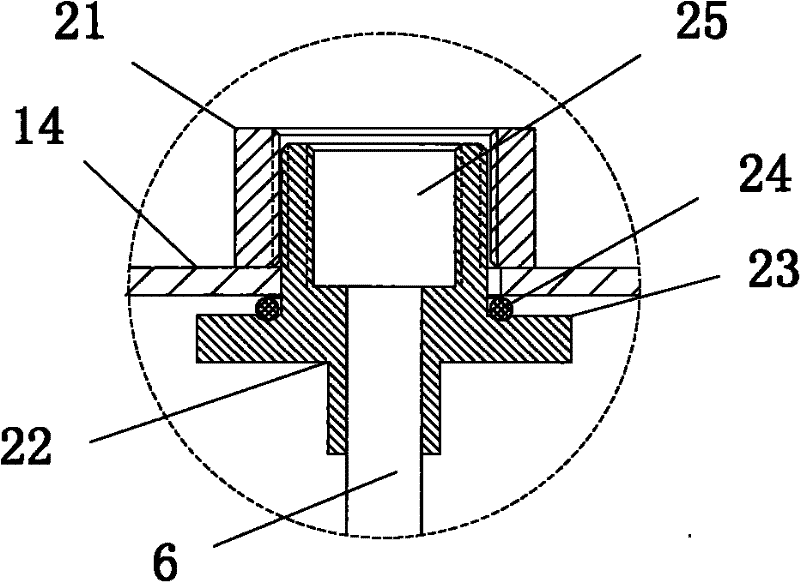

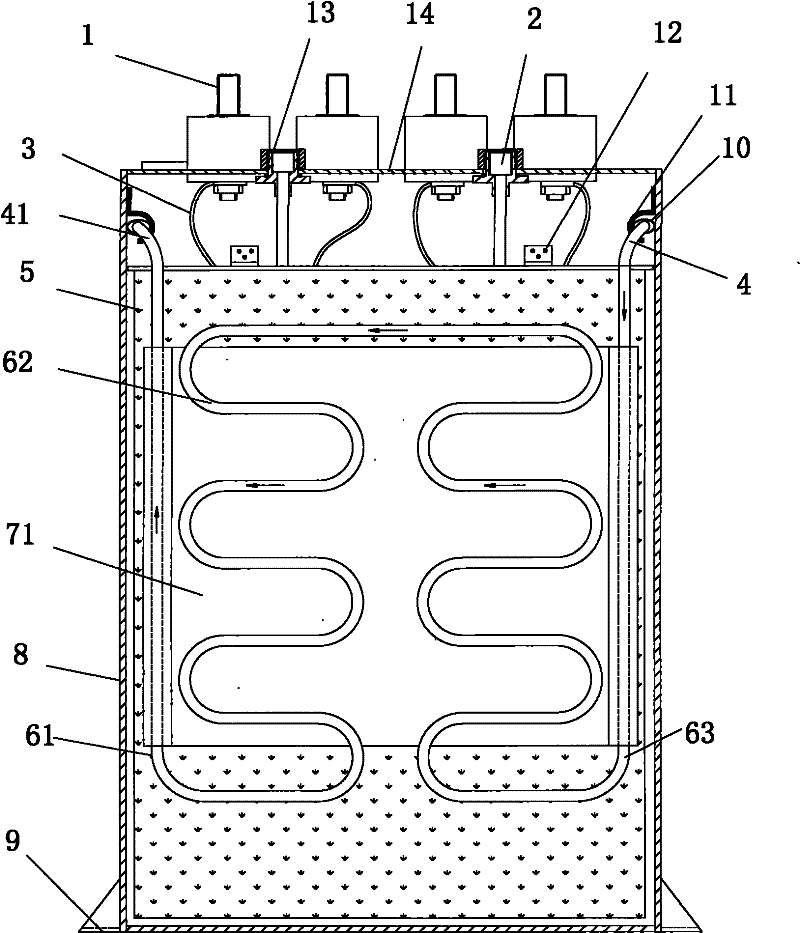

[0014] like Figure 1 to Figure 5 As shown, the present invention includes a housing 8, a capacitor core group 5 and a cover plate assembly 14. There are four electrode lead-out terminals 1 on the cover plate assembly 14, and the capacitor core group 5 is fixed in the housing 8 by a bracket 12. The core set 5 is electrically connected to the electrode lead-out terminal 1 through the cable 3 , and the bottom of the housing 8 has a mounting base 9 .

[0015] The casing 8 is provided with a cooling device 6 made of a coiled copper metal heat pipe. The cooling device is arranged at the gap between the gold-sprayed surfaces 51, 52 on both sides of the capacitor core group 5 and the casing 8, such as Figure 4 and Figure 5 As shown, it is composed of coiled section pipe bodies 62 and 66 on both sides, straight pipe section pipe bodies 61, 63, 64 and 68, and transition section pipe bodies 4, 41. The pipe body inlet and outlet ends 65, 67 of the cooling device 6 are composed of capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com