Liquid heater with low power consumption, control method and manufacturing method thereof

A heating device and power consumption technology, applied in the field of liquid heating devices of automatic drinking fountains or beverage diverters, can solve the problems of easy formation of cracks, high heating temperature, large heating unit, etc., and achieve the promotion of liquid heating and high heat transfer. coefficient, the effect of fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

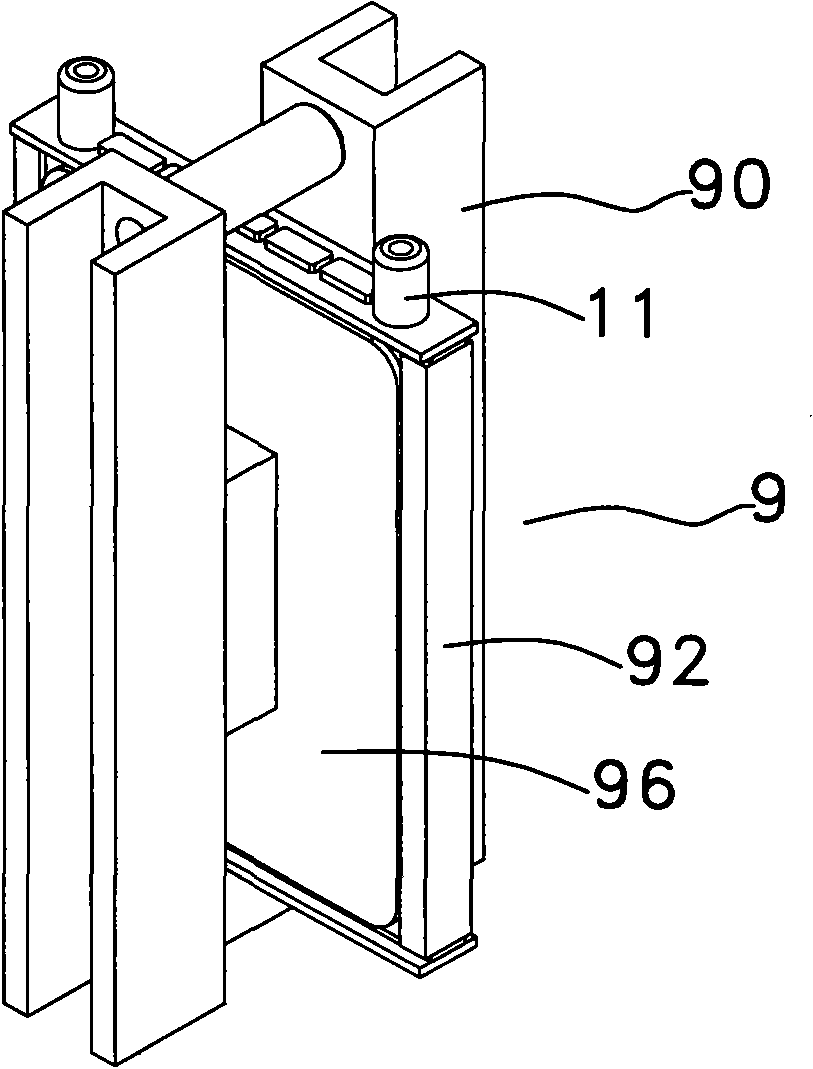

[0056] attached Figure 1 to Figure 2 It is a specific embodiment of the core assembly 9 in a liquid heating device (such as a drinking water heating device). The core 92 shown in this embodiment is integrally manufactured with the heat diffusion components 64 on both sides and the channel. The core 92 is actually extruded from aluminum, such as aluminum alloy, and the two ends are connected by cover plates to form the core as a whole, as shown in the attached figure 1 And attached figure 2 shown. After the core 92 is formed, two heat-generating components 96 are disposed opposite to the two surfaces of the core 92 and sandwich the core. After the two heating components 96 have been configured, the two bracket components 90 and the corresponding pressing blocks are relatively arranged on the other surface of the heating component 96. The bracket component 90 provides a pressure perpendicular to the core assembly 9 to make the heating component 96 is attached to the core 9...

Embodiment 2

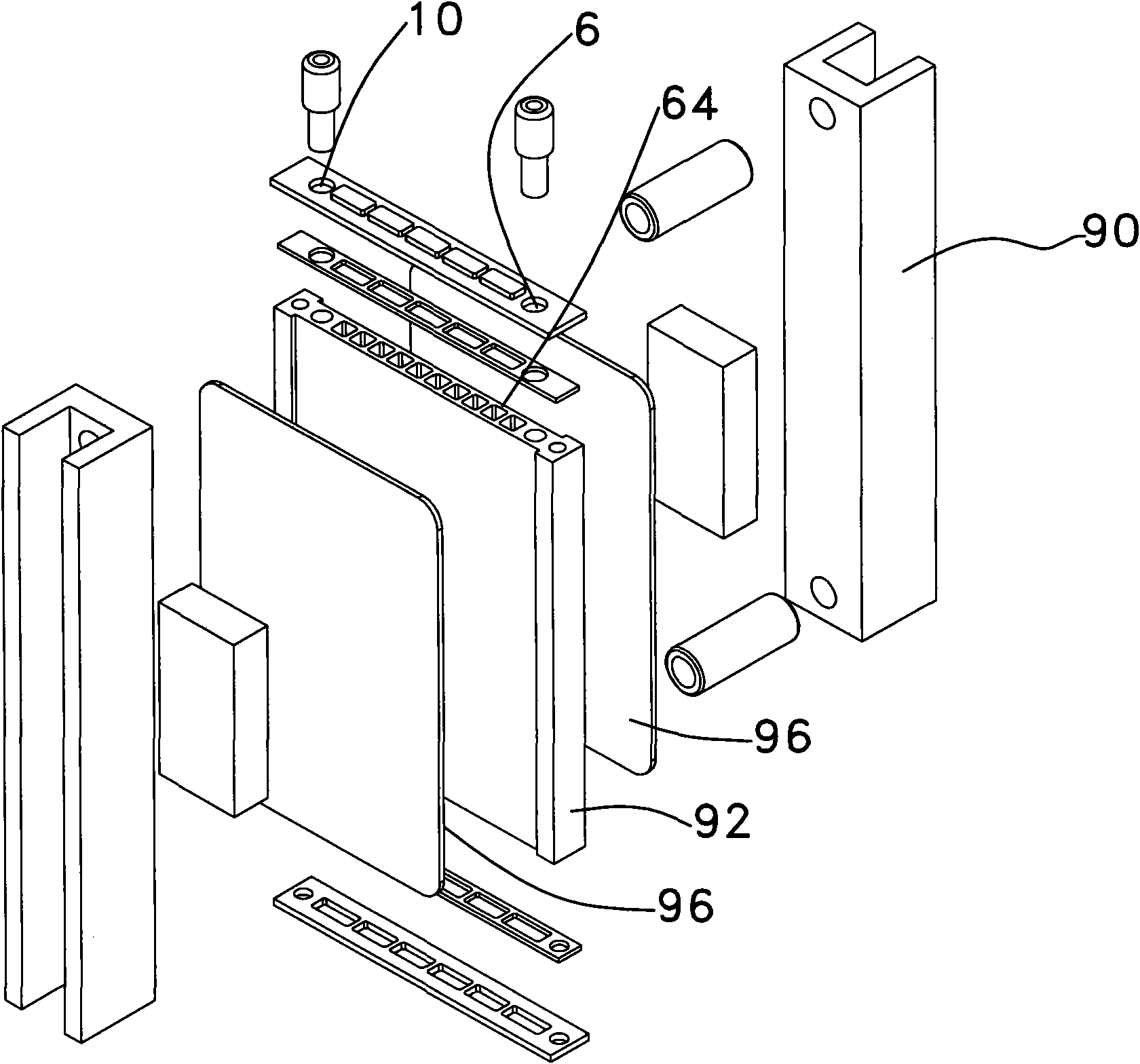

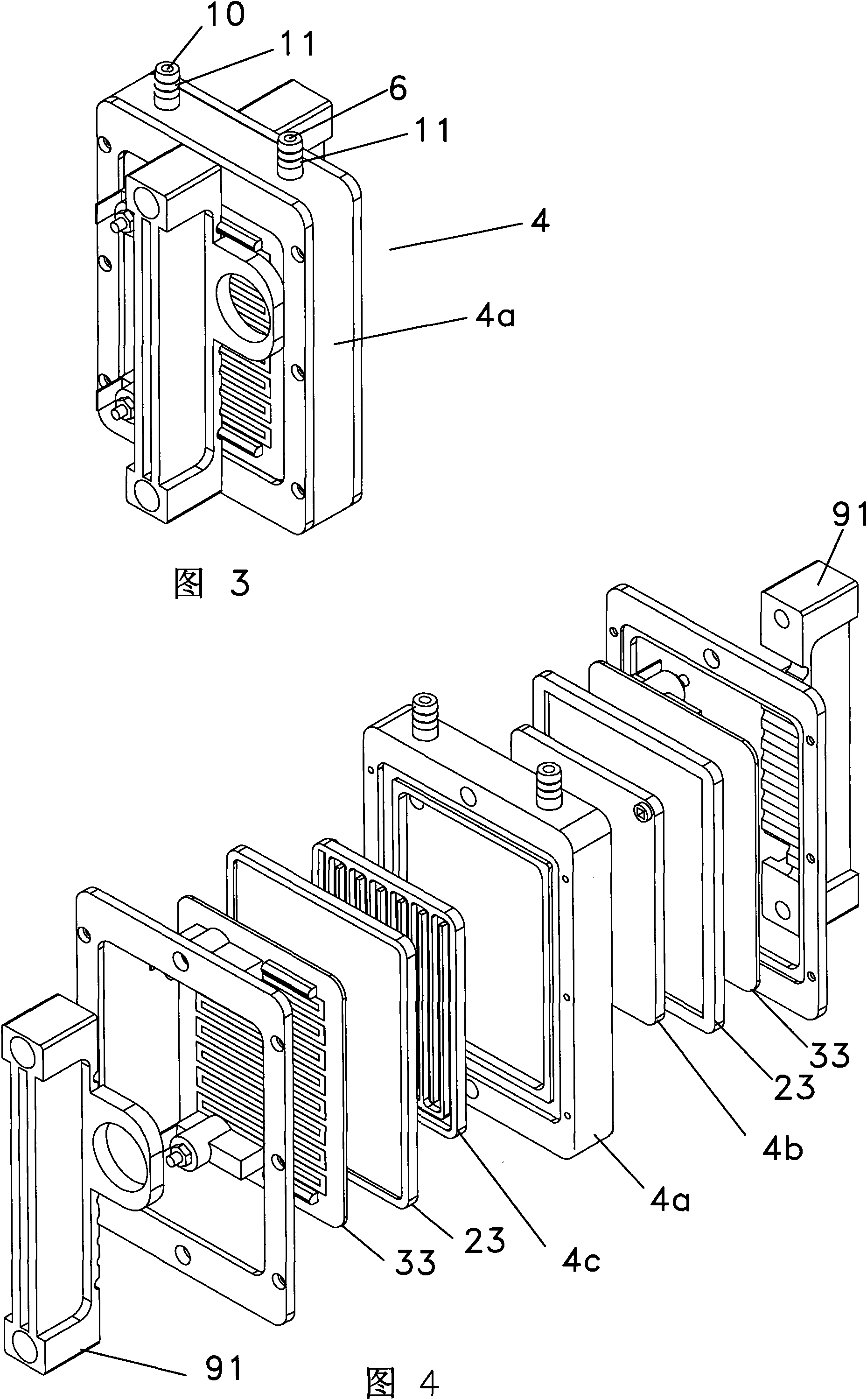

[0060] attached image 3 to attach Figure 4 Shown is another specific embodiment of a core assembly within a liquid heating apparatus. as attached image 3 As shown, the liquid heating device inner core assembly is generally indicated at 4 . The inner core assembly 4 of the liquid heating device is provided with an inlet 6 , an outlet 10 and two joints 11 .

[0061] attached Figure 4 to attach image 3 An exploded view of the core assembly inside a medium liquid heating device. The liquid heating core assembly 4 includes a core base assembly 4a in the middle of the assembly. Two sides of the core base assembly 4a respectively provide a space for accommodating the channel 4b and the channel 4c.

[0062] In this embodiment, the core assembly 4 is different from the embodiment 1. The core assembly of embodiment 1 is manufactured by integrating the channel and the thermal diffusion part. However, in Embodiment 2, the core assembly 4 is respectively configured as a core ...

Embodiment 3

[0065] attached Figure 5 to attach Figure 6 Shown is another embodiment of a core assembly within a liquid heating apparatus. as attached Figure 5 The liquid heating unit inner core assembly is generally indicated at 2 as shown. Two joints 11 are attached to the top of the core part 2a in this liquid heating device.

[0066] Figure 6 It is an exploded view of each main part of the core components in the liquid heating device. The core assembly 2 of the liquid heating device comprises a core part 2 a in the middle part of the device 2 . The core part 2a provides a liquid inlet level 6 through which liquid is introduced into the core part 2a. The core part 2a also provides a liquid outlet level 10 through which the heated liquid leaves the core part 2a. A thermal diffusion component 24 covers the core component 2 a to form a channel, a heating element 32 is attached to the other surface of the thermal diffusion component 24 , a pressure ring 36 and a base 38 form a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com