Cylinder head of an internal combustion engine with integrated exhaust manifold and cooling jacket

A technology for exhaust manifolds and cylinder heads, which is applied to cylinder heads, exhaust devices, cylinders, etc., to achieve the effect of reducing the risk of thermal overheating and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

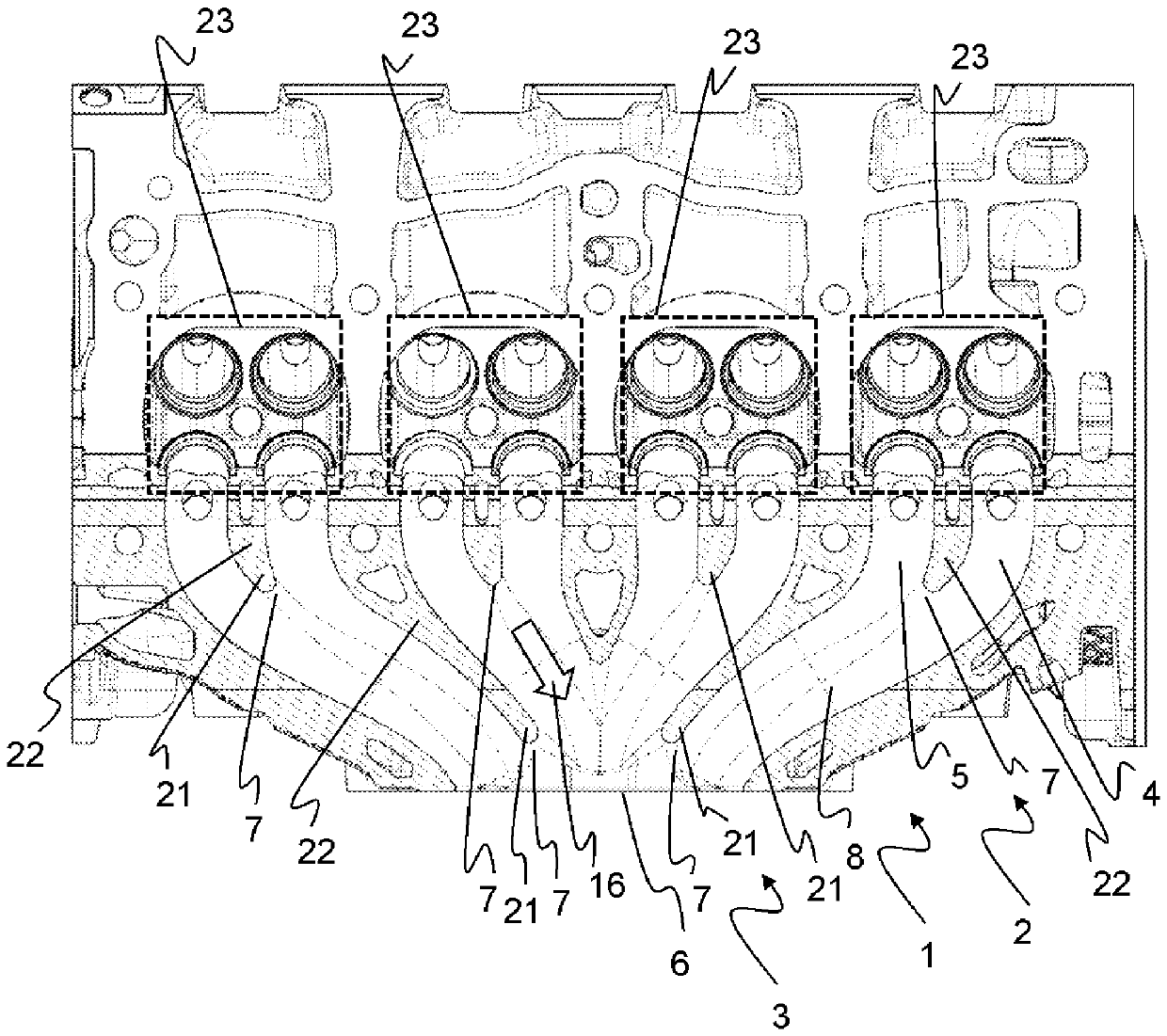

[0074] figure 1 An internal combustion engine 2 with a cylinder head 1 with an integrated exhaust manifold 3 is shown in a view from above. The exhaust manifold 3 here has eight exhaust-gas-conducting lines 4 , 5 which run from the four combustion chambers 23 in the direction of the exhaust manifold outlet 6 . Two of them, denoted here as the first line 4 and the second line 5 , lead the exhaust gas from the combustion chamber 23 to the flow connection 7 . The lines 4 , 5 are arranged approximately next to each other and are separated from each other by a common wall 22 . The lines 4 , 5 are joined (in succession) upstream of the exhaust manifold outlet 6 at a further flow connection point 7 (in the direction of flow 16 ) into a (larger) collecting line 8 , wherein the line 4 , 5 are separated from each other by the end region 21 of the wall 22 just before each flow connection point 7 .

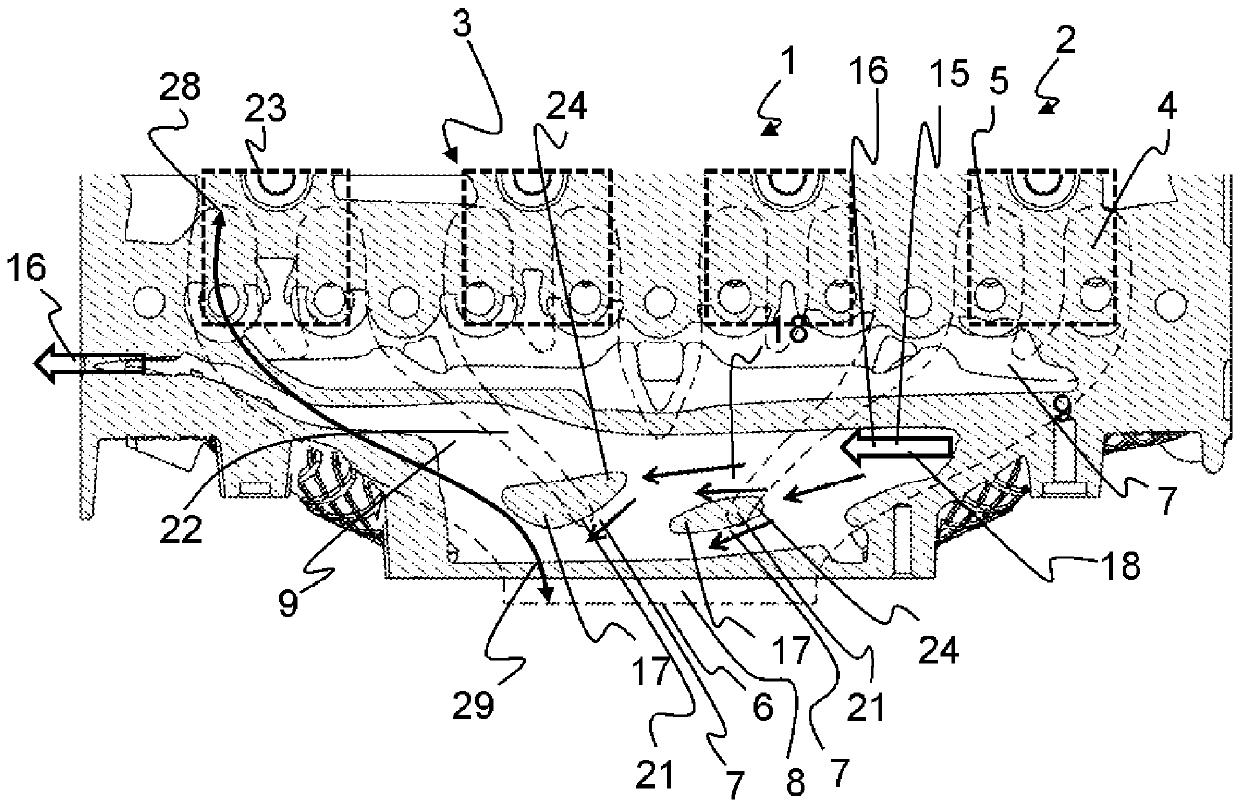

[0075] figure 2 The cylinder head 1 with integrated exhaust manifold 3 and exhaust m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com