Optimization method of tuned mass damper of elastic support dry friction

A technology of tuning mass damping and elastic support, which is applied in the field of machinery, can solve problems such as noise pollution, lower product quality, production efficiency, tool and machine tool life, and affect the physical and mental health of operators, and achieve good cutting stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

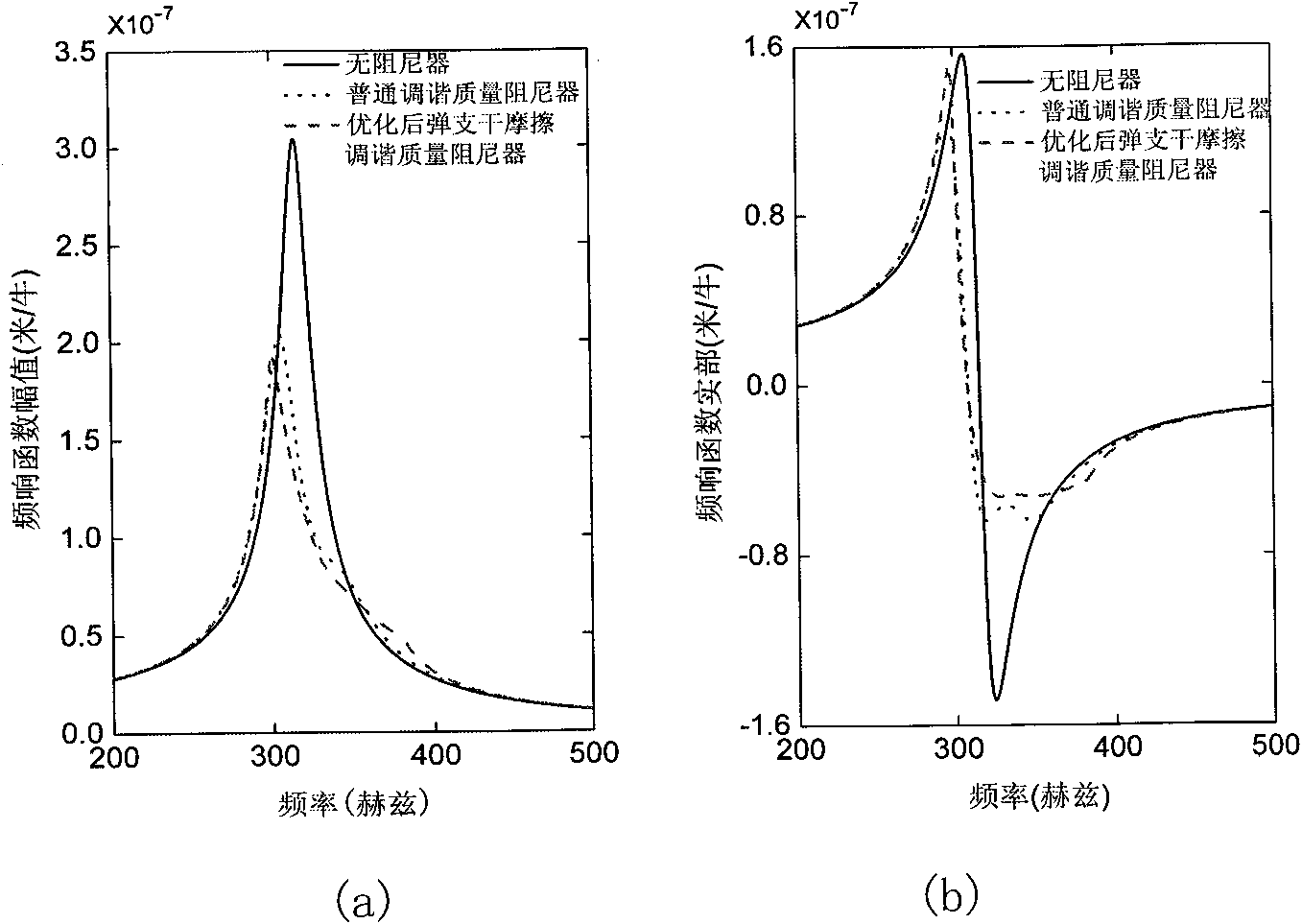

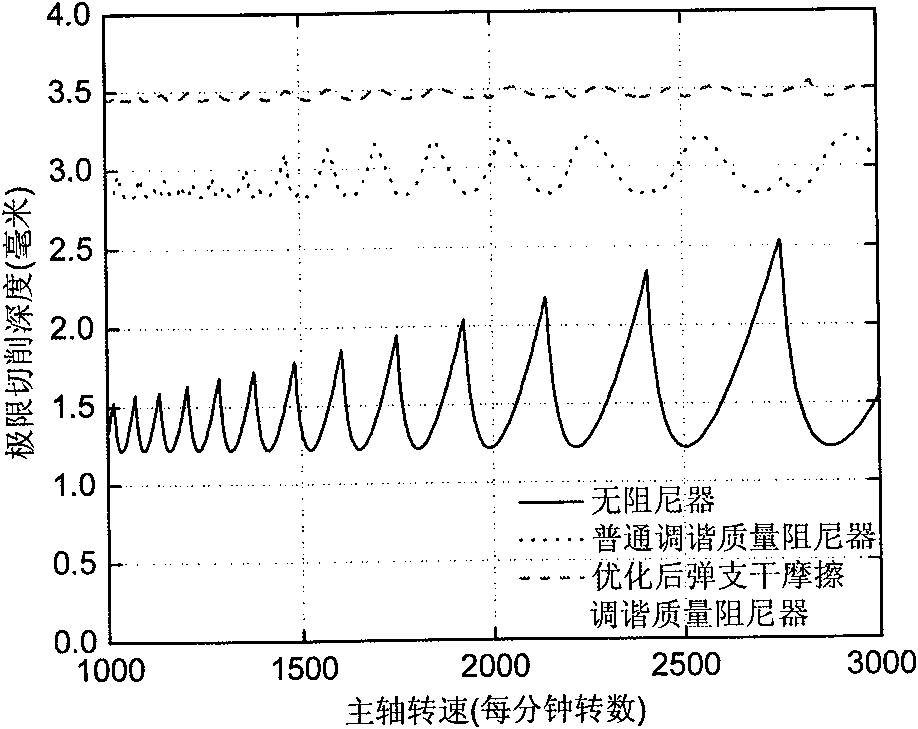

[0021] Combine below Figure 1 ~ Figure 3 The optimization method of elastically supported dry friction tuned mass damper as a tuned mass damper with an elastically supported dry friction damper in series is introduced.

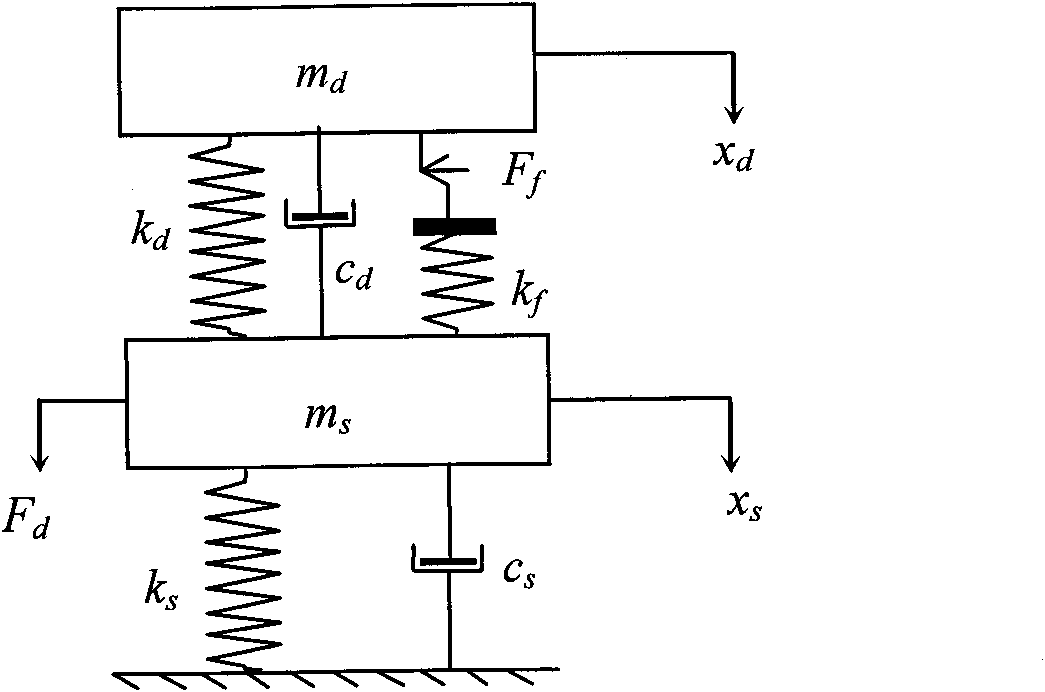

[0022] first as figure 1 As shown in , the dynamic model of the cutting system with elastic support series dry friction tuned mass damper is established, and the cutting process system is modeled as a single-degree-of-freedom dynamic system, F d is the dynamic cutting force, x s is the vibration displacement of the controlled cutting system, x d is the vibration displacement of the damper vibrator.

[0023] In the figure, the main dynamic parameter of the damper is the vibrator mass (m d ), stiffness (k d ), damping coefficient (c d ), elastic support stiffness (k f ) and friction damper friction (F f ), the damper natural frequency f d =(k d / m d )^ 0.5 , the damping ratio (ξ d ) = c d / 2 / (m d k d )^ 0.5 .

[0024] In the figure, the main d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com