Absorption control method of ammonia inside SCR (Silicon Controlled Rectifier) catalyst

A SCR catalytic converter, adsorption control technology, applied in chemical instruments and methods, separation methods, electronic control of exhaust gas treatment devices, etc., can solve the problem of not considering the control measures of ammonia gas storage and the amount of ammonia gas escaped from catalytic converters , Inaccurate calculation results of ammonia gas accumulation, etc., to achieve the effects of curbing ammonia gas leakage, eliminating response lag, simplifying calculation content and SCR system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

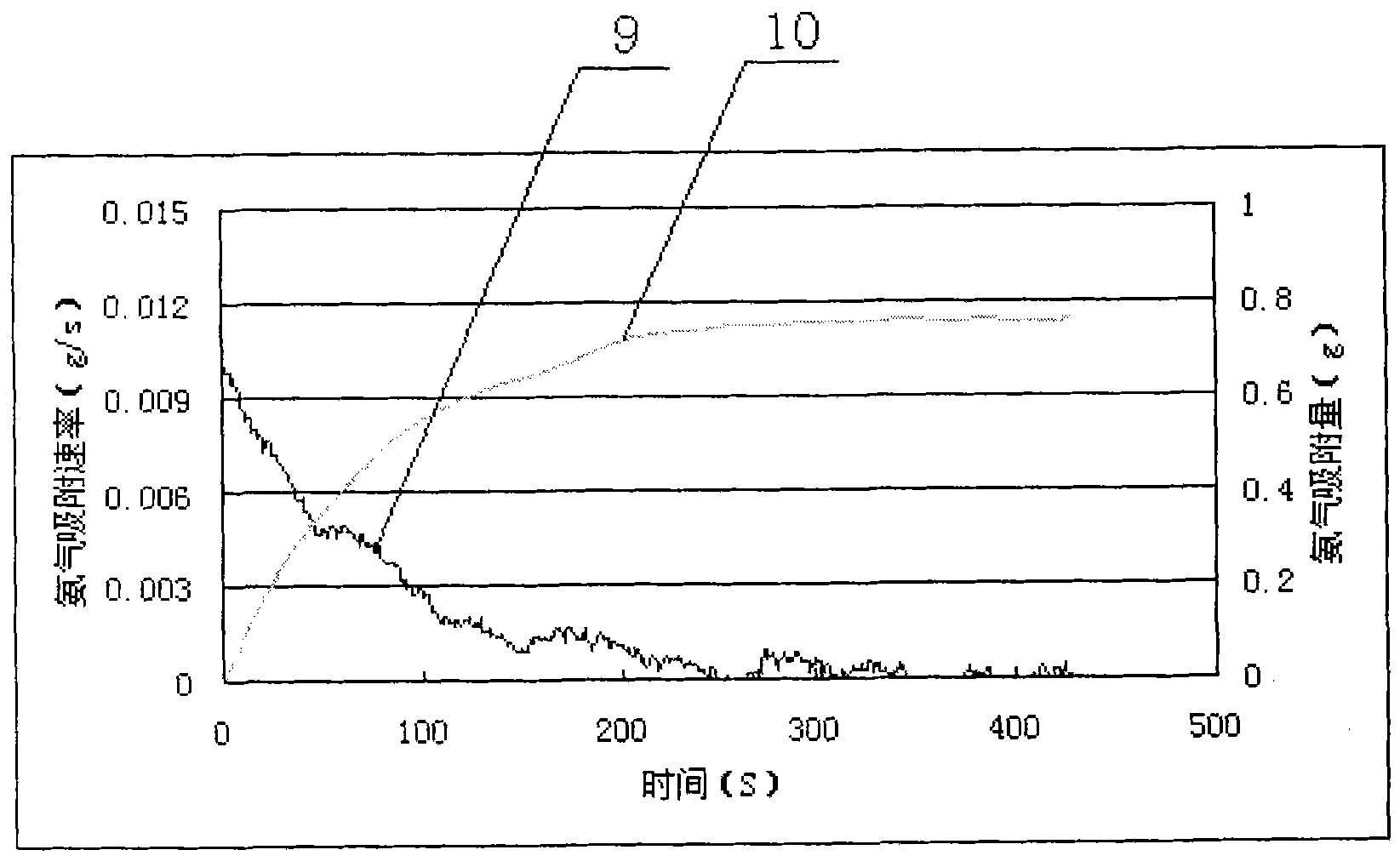

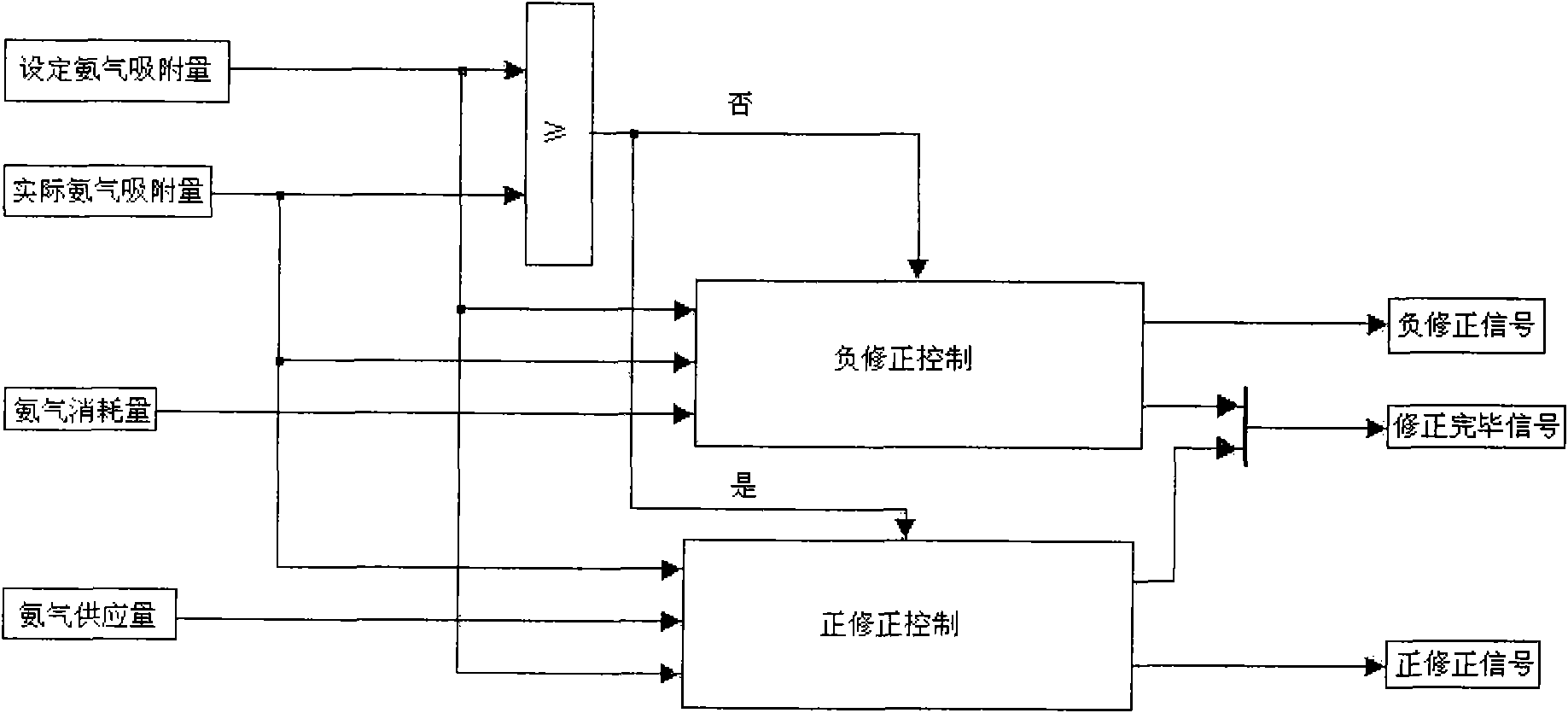

[0055] After the engine starts, after a period of time, it enters the temperature range 1, and the background ammonia adsorption amount is 0. Set the ammonia adsorption amount as the saturated ammonia adsorption amount at the current temperature.

[0056] The engine has been running for 30 seconds in temperature range 1, and the continuous injection time of urea is 20 seconds, then the saturated ammonia adsorption amount Q in the current temperature range is 1max = 0.201g.

[0057] After the engine runs in temperature range 1 for 30 seconds, it enters into temperature range 2, then background ammonia adsorption amount = ammonia adsorption amount in the previous temperature range = 0.201g. And the current saturated ammonia adsorption amount = Q 2max = 0.184g.

[0058] Therefore, at the moment of entering the temperature range 2, the actual adsorption amount of ammonia gas by the catalytic converter = background ammonia adsorption amount = 0.201 g.

[0059] Since the actual ...

Embodiment 2

[0061] After the engine has been running in temperature range 2 for a period of time, the negative correction has ended and it enters temperature range 1, then the background ammonia adsorption amount is Q 2max That is 0.184g. The set ammonia adsorption amount is still the saturated ammonia adsorption amount at the current temperature.

[0062] Therefore, at the moment of entering the temperature range 2, the actual adsorption amount of ammonia gas by the catalyst = the background ammonia adsorption amount = 0.184g. Since the actual adsorption amount of 0.184g of ammonia by the catalytic converter is less than the current saturated ammonia adsorption amount of 0.201g, the positive correction control is activated. The increased ammonia adsorption was calculated from the increased flow rate of urea. Then add the actual adsorption amount of ammonia gas of 0.184g to the increased amount of ammonia gas adsorption to obtain a new actual adsorption amount of ammonia gas, and compar...

Embodiment 3

[0064] Set the ammonia adsorption amount to 70% of the saturated adsorption amount at the current temperature.

[0065] The engine has been running for 20 seconds in the temperature range 1, and the continuous injection time of urea = 5 seconds, then according to the adsorption function f 1 (t), the ammonia adsorption amount=0.08g in the current temperature range;

[0066] After the engine runs in temperature range 1 for 20 seconds and enters temperature range 2, then background ammonia adsorption amount = ammonia adsorption amount in the previous temperature range = 0.08g;

[0067] Ammonia saturated adsorption capacity in the current temperature range = Q 2max =0.184g; Set ammonia adsorption capacity=0.184×70%=0.118g;

[0068] At the moment of entering the temperature range 2, the actual ammonia adsorption amount of the catalyst = the background ammonia adsorption amount = 0.08g;

[0069] Since the actual adsorption amount of ammonia gas

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com