Application of non-woven fabric in isolating and sliding in building projects

A non-woven and needle-punched non-woven technology, applied in construction, bridge construction, bridge parts, etc., can solve problems such as affecting building safety and losing sliding function, and achieve the effects of ensuring safety, eliminating stress and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

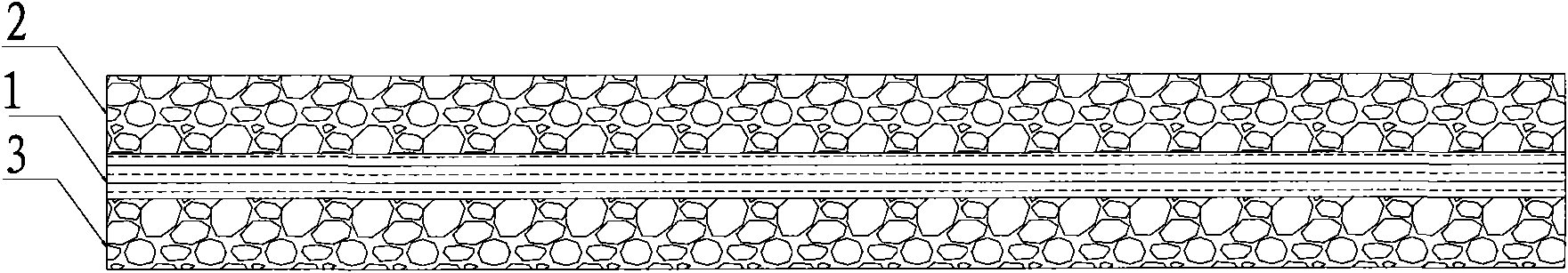

[0022] Please refer to figure 1 and figure 2 As shown, in this example, polypropylene staple fiber needle-punched non-woven fabric is used to isolate the road surface on the bridge from the bridge body. The bridge body 3 is a rigid structure. During construction, the non-woven fabric 1 is laid on the bridge body 3, and then concrete mortar or road asphalt is poured on the non-woven fabric 1 to form the road surface 2 on the bridge. The road surface 2 is consolidated with the non-woven fabric 1 as a whole, but it is not consolidated with the bridge body 3, but is in free contact, which can produce a certain sliding effect. The sliding action can eliminate the sudden stress generated between the road surface and the bridge body, can eliminate the stress caused by temperature changes, can improve the performance of compression resistance, shear resistance, creep resistance, etc., and avoid cracking and damage of the road surface. service life of the pavement. At the same time...

Embodiment 2

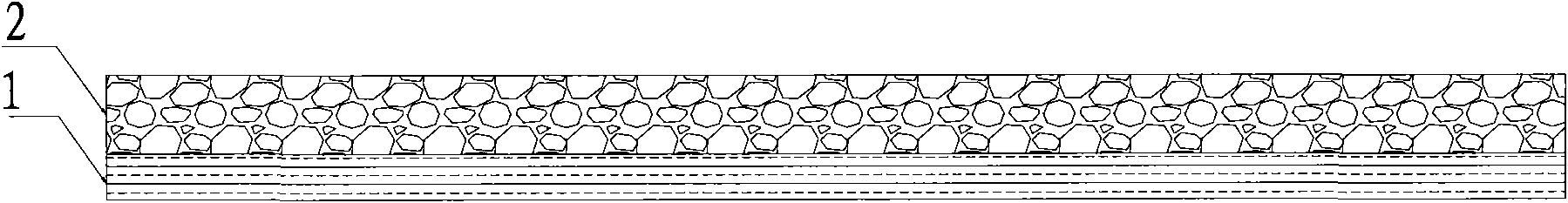

[0031] Aiming at the problem that the isolation and sliding layer structure is easy to accumulate water and damp, which causes the steel bars in the concrete to rust and affects the structural strength and service life, the non-woven fabric is pre-treated with water repellency, which basically solves the problem of water accumulation and damp in the sliding layer structure. question. When applied to the isolation of rigid structures, the water-repellent polypropylene staple fiber needle-punched non-woven fabric is bonded to the surface of the base rigid structure with viscose, and then concrete mortar or asphalt mortar is poured on the non-woven fabric to form The upper rigid structure, the water-repellent non-woven fabric can delay or prevent concrete or asphalt mortar from penetrating into the isolation and sliding layer through the non-woven fabric, affecting the isolation and sliding effect.

Embodiment 3

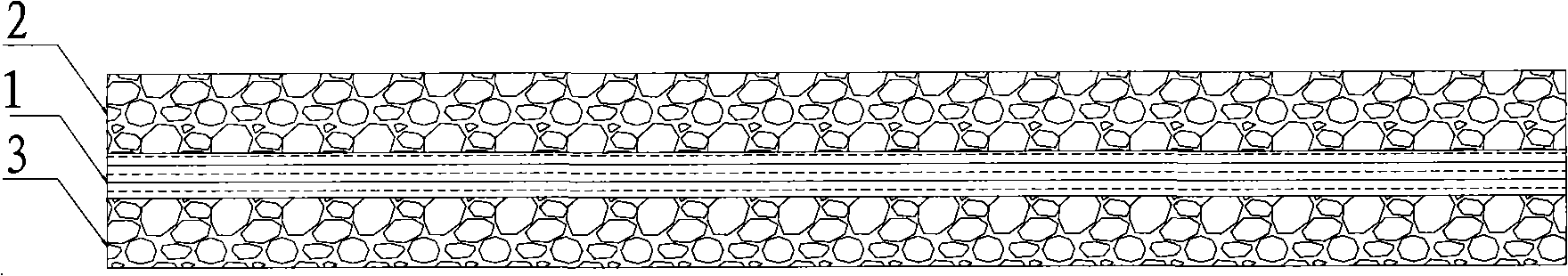

[0033] For the special requirements of isolation and sliding, the surface of the non-woven fabric can be treated differently to adapt to different interfaces. Through heat treatment, the roughness of one side of the non-woven fabric can be controlled according to the requirements of the project, so that the coefficient of friction with the contact surface can be adjusted between 0.2-0.8 to ensure its sliding function and resistance requirements; the other side keeps short fibers The fluffy surface of the non-woven fabric makes it have a better degree of bonding and a larger coefficient of friction when combined with concrete or glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com