Method for preparing nano-crystalline photocatalysis titanium dioxide fiber

A technology of crystalline photocatalytic titanium dioxide and titanium hydroxide, which is applied in fiber treatment, textiles and papermaking, artificial filaments made of inorganic raw materials, etc., and can solve the problem of complex spinning solution preparation process, high cost of raw materials, and difficulty in meeting the requirements of dynamic continuous water treatment and other problems, to achieve the effect of spinnability, less burning out and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

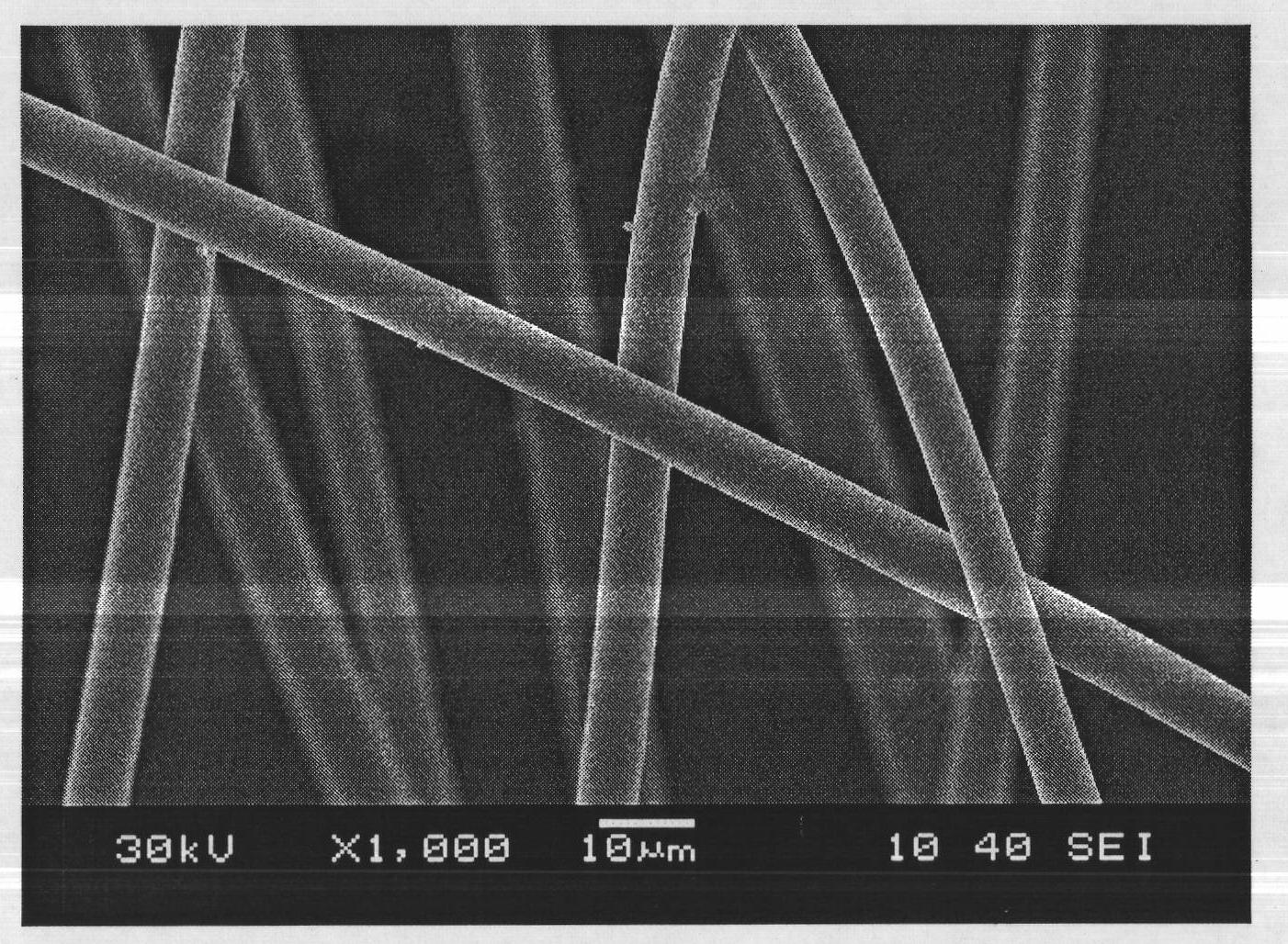

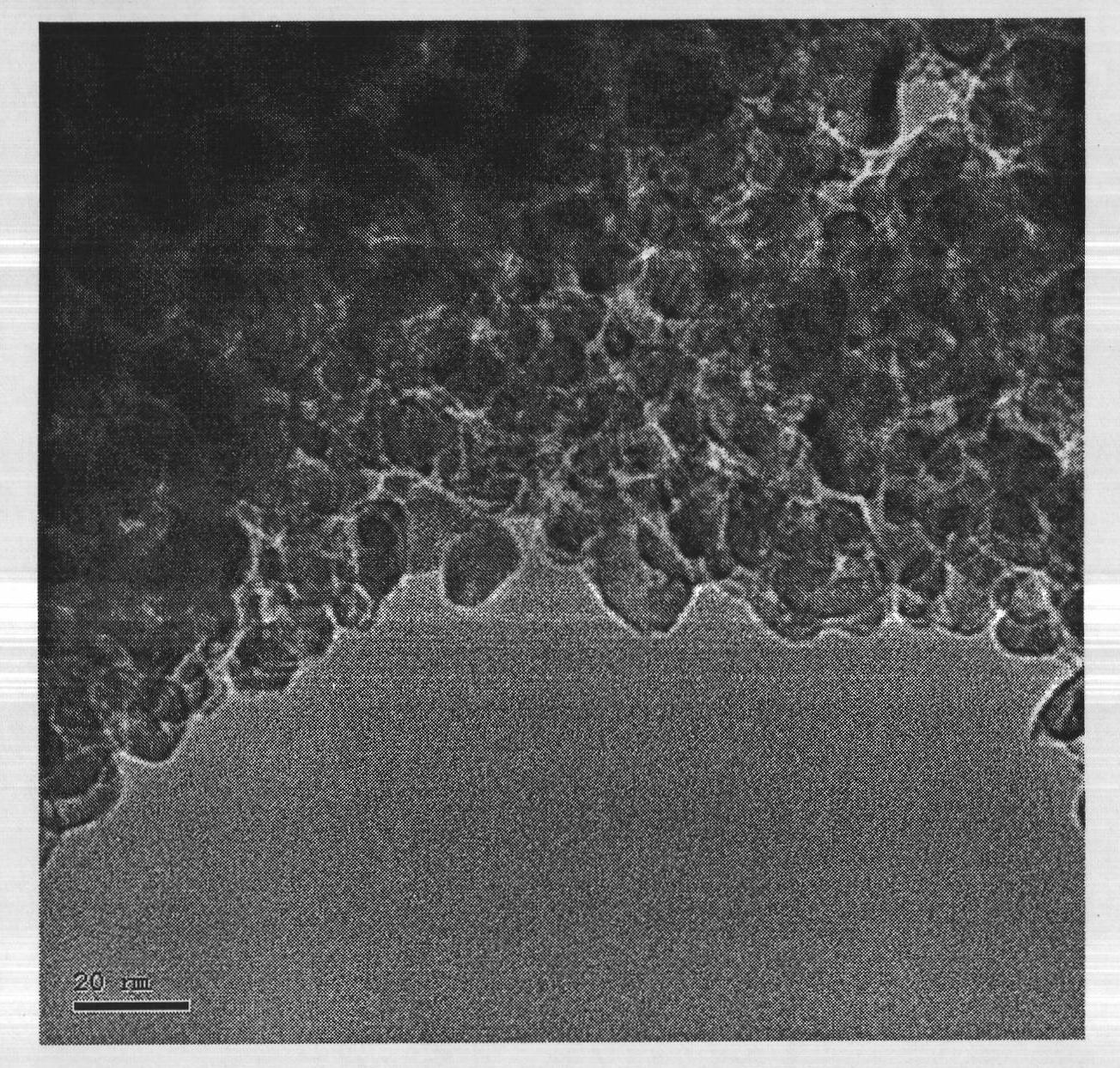

[0015] The preparation method of the nanocrystalline photocatalyzed titanium dioxide fiber of the present invention adopts titanium hydroxide, aqueous hydrogen peroxide solution, organic acid, and silica sol as raw materials to synthesize polytitanium sol spinning solution, obtains polytitanium gel fiber through centrifugal spinning, and then passes water Nanocrystalline photocatalytic titania fibers obtained by steam activation heat treatment.

[0016] Among them, the process of synthesizing polytitanium sol spinning solution is: according to titanium hydroxide: titanium hydroxide, hydrogen peroxide, organic acid are mixed together according to the molar ratio of 1: 2 ~ 4: 0.7 ~ 1.5, stirring and 5 ℃~25℃, react for 24h~72h, and obtain an orange-yellow transparent solution. According to the final composition of nanocrystalline photocatalyzed titanium dioxide fiber, TiO 2 : SiO 2 = 1mol: 0.1-0.2mol ratio, the conversion amount takes the corresponding volume of silica sol and a...

Embodiment 1

[0024] (1) Synthetic polytitanium sol spinning solution

[0025] According to the ratio of titanium hydroxide: hydrogen peroxide: lactic acid = 1mol: 2mol: 0.7mol, weigh 98g of titanium hydroxide, add concentration of 30% hydrogen peroxide aqueous solution 205mL, lactic acid 52ml, stir and react for 24h at 10°C , to obtain an orange-yellow transparent solution, according to the TiO in the final composition of the fiber 2 : SiO 2 =1mol:0.1mol ratio, measure SiO 2 Add 60ml of silica sol with a content of 10% to the solution obtained above, and age the resulting mixed solution at room temperature for 72 hours, then distill under reduced pressure at 70°C until a polytitanium sol with a viscosity of 30Pa·s is obtained for spinning liquid.

[0026] (2) centrifugal spinning

[0027] The polytitanium sol spinning solution is injected into the centrifugal spinning disc, and the spinning solution is thrown out from a small hole with a diameter of 0.5mm under the action of centrifuga...

Embodiment 2

[0031] As described in Example 1, the difference is that titanium hydroxide in step (1): the ratio of hydrogen peroxide=1mol: 2mol is changed to 1mol: 4mol, and the concentration of aqueous hydrogen peroxide is changed to 60% by 30%, React for 72h under the condition of stirring and 10°C, according to the TiO in the final composition of the fiber 2 : SiO 2 =1mol:0.2mol ratio, measure SiO 2 40ml of silica sol with a content of 30%, and the resulting mixed solution was statically aged at room temperature for 120h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com