Nano composite titanium-chromium-silicon nitride cutter coat and preparation method thereof

A silicon nitride, nano-composite technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problem of not meeting the better performance of the tool, and achieve practical use value and meet better performance. Demand, mechanical wear resistance and effect of improved abrasive wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

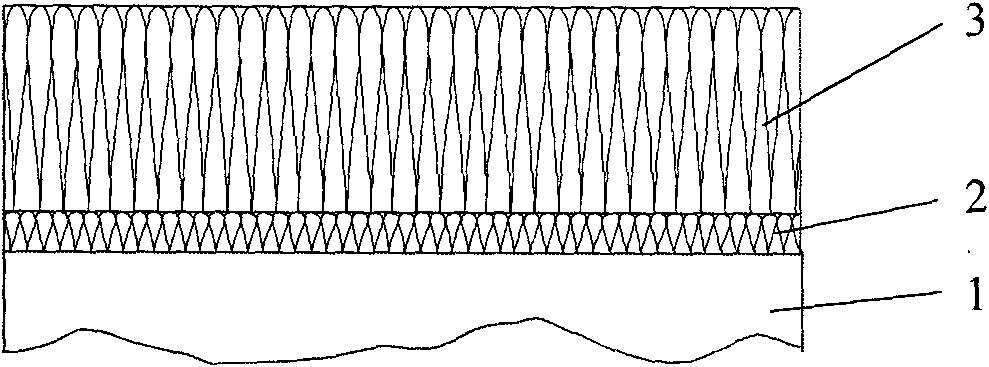

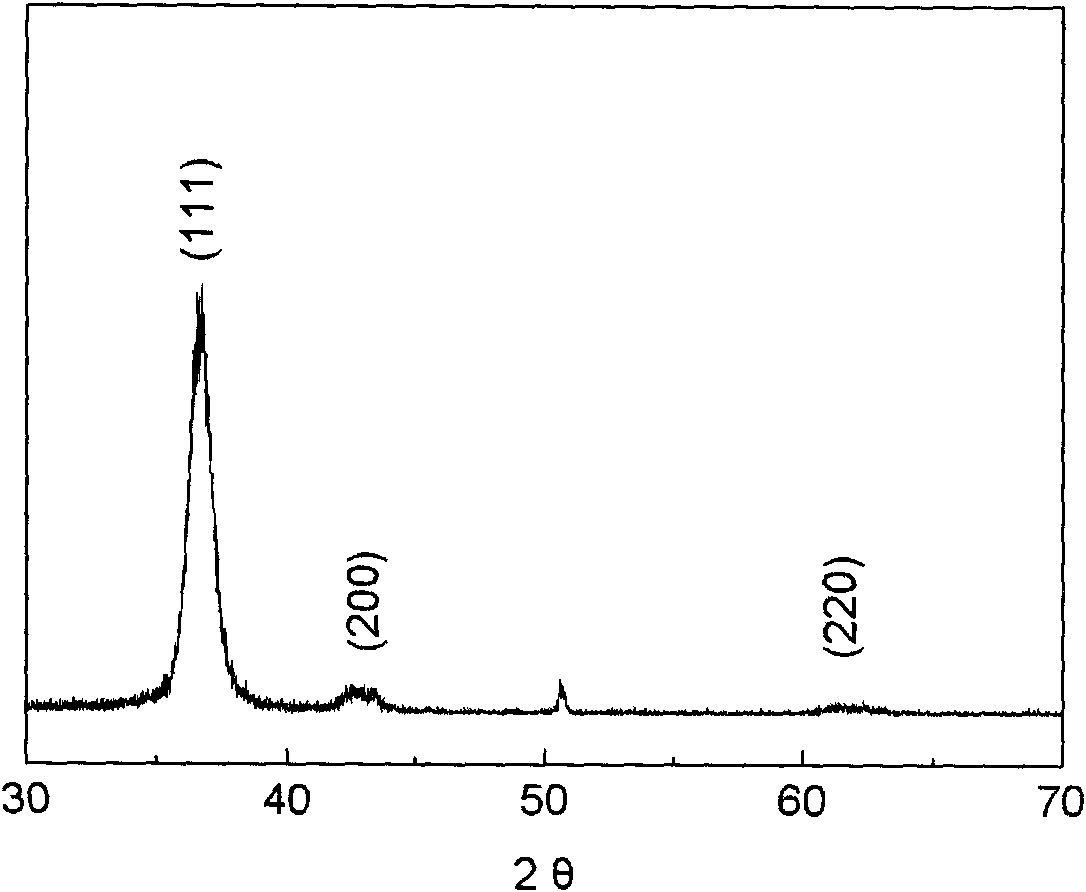

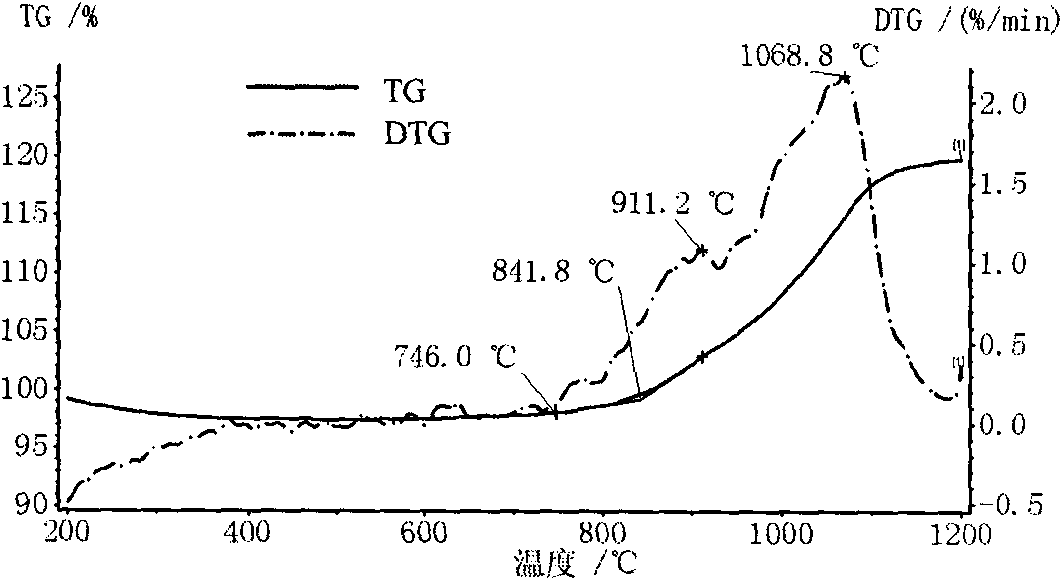

[0021] The present invention adopts physical vapor deposition technology to coat a layer of titanium / titanium nitride transition layer on the specific surface of WC / Co cemented carbide cutter, and then coats a layer of titanium chromium silicon nitride coating material, wherein the thickness of the transition layer 0.1-0.5 microns, and the thickness of the titanium chromium silicon nitride coating is 1-4 microns. The coating formulations are as follows:

[0022] Titanium 38at.%, Chromium 20at.%, Silicon 6at.%, Nitrogen 36at.%;

[0023] Titanium 30at.%, Chromium 36at.%, Silicon 4at.%, Nitrogen 30at.%;

[0024] Titanium 60at.%, Chromium 6at.%, Silicon 4at.%, Nitrogen 30at.%;

[0025] Titanium 30at.%, Chromium 6at.%, Silicon 14at.%, Nitrogen 50at.%;

[0026] Titanium 30at.%, Chromium 20at.%, Silicon 20at.%, Nitrogen 30at.%;

[0027] Titanium 30at.%, Chromium 26at.%, Silicon 14at.%, Nitrogen 30at.%;

[0028] The cutting tool substrate pretreatment process involved in the inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com