Polyurethane (PU) paint for decorating magnesium alloy surface

A surface decoration, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex process, high energy consumption, wear resistance, weather resistance and insufficient appearance decoration, achieve high metallic luster, avoid waste, The effect of multiple superiority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

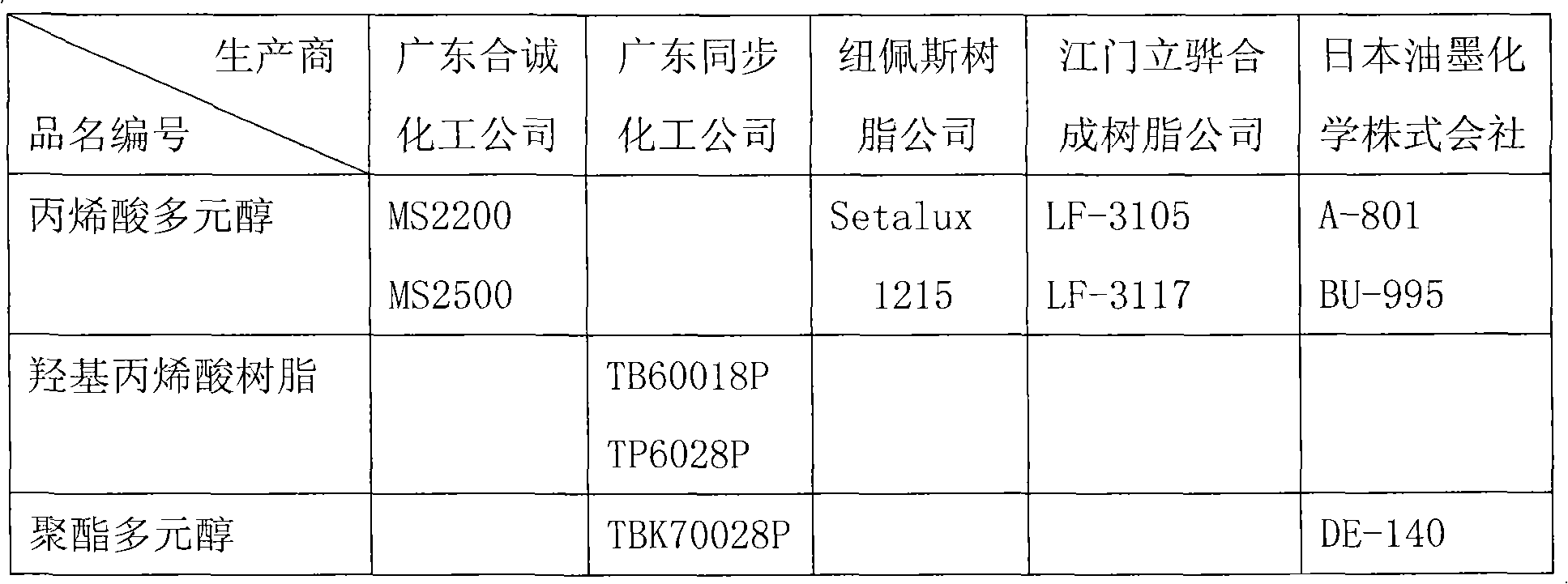

[0016] The weight percent of PU primer: acrylic polyol MS2200 35%, hydroxyl acrylic resin TB60018P 10%, nitrocellulose (1 / 2 second) 4%, wrapped aluminum silver paste TR3100 (Japan Asahi Kasei) 6%, closed curing agent MF -K60X (Japan Asahi Kasei) 8%, leveling agent BYK-306 (German BYK) 0.99%, anti-settling agent REOLOSIL (Japan TOKUYAMA) 3%, drier organotin 0.01%, mixed solvent 33%.

[0017] Accurately weigh the above components and add them to the dispersing vessel one by one, control the dispersing temperature (less than 60°C), stir evenly at a medium speed (about 2 hours), filter and pack.

[0018] The weight percentage of PU topcoat: acrylic polyol MS250025%, hydroxyl acrylic resin TP6028P 8%, polyester polyol TBK70028P 15%, 1,4-butanediol 3%, closed curing agent MF-K60X (Japan Asahi Kasei) 15 %, transparent red pigment 3%, leveling agent BYK-306 (Germany BYK) 1%, anti-salt spray additive KP392 (Japan Shin-Etsu) 0.99%, drier organotin 0.01%, mixed solvent 29%. The mixing m...

Embodiment 2

[0020] The weight percent of PU primer: acrylic polyol A-80138%, hydroxyl acrylic resin TB60018P 8%, nitrocellulose (1 / 2 second) 4%, wrapped aluminum silver paste FZH-390 (Japan Toyo) 6%, closed type Curing agent MF-K60X (Japan Asahi Kasei) 10%, leveling agent BYK-306 (German BYK) 0.99%, anti-settling agent REOLOSIL (Japan TOKUYAMA) 3%, drier organotin 0.01%, mixed solvent 30%.

[0021] The weight percentage of PU topcoat: acrylic polyol BU-99528%, hydroxyl acrylic resin TP6028P 6%, polyester polyol DE-14013%, 1,4-butanediol 4%, closed curing agent MF-K60X (Japan Asahi Kasei) 13%, transparent blue pigment 2%, leveling agent BYK-306 (Germany BYK) 1%, anti-salt spray additive KP392 (Japan Shin-Etsu) 0.99%, drier organotin 0.01%, mixed solvent 32% . The mixing preparation method of the above-mentioned PU coating is the same as that of Example 1, and the coating properties are shown in Table 2.

Embodiment 3

[0023] The weight percent of PU primer: acrylic polyol Setalux1215 34%, hydroxyl acrylic resin TB60018P14%, nitrocellulose (1 / 2 second) 6%, wrapped aluminum silver paste FZ-C6390 (Japan Toyo) 6%, closed curing agent MF-K60X (Asahi Kasei, Japan) 10%, leveling agent BYK-330 (BYK, Germany) 1%, anti-settling agent REOLOSIL (TOKUYAMA, Japan) 2.99%, drier organotin 0.01%, mixed solvent 26%.

[0024] Weight percentage of PU topcoat: acrylic polyol BU-99514%, acrylic polyol MS2500 15%, hydroxyl acrylic resin TP6028P 6%, polyester polyol TBK70028P 12%, 1,4-butanediol 4%, closed type curing Agent MF-K60X (Japan Asahi Kasei) 15%, transparent purple pigment 2%, leveling agent BYK-333 (Germany BYK) 0.99%, anti-salt spray additive KP392 (Japan Shin-Etsu) 1%, drier organotin 0.01% , mixed solvent 30%.

[0025] The mixing preparation method of the above-mentioned PU coating is the same as that of Example 1, and the coating properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com