Method for preparing epoxy soybean oil-based polyalcohol from epoxy soybean oil

A technology of epoxidized soybean oil and oil-based polyols, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. The effect of poor conditions and reduced dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a high-pressure reactor equipped with magnetic stirring and a volume of 100ml, add 20g of epoxidized soybean oil, 24g of methanol, 4g of acetone, 4g of water and 3g of NaZSM-5, and raise the temperature to 120°C at a heating rate of 5°C / min. After reacting for 20h, the material is discharged to obtain an orange-yellow liquid. After the reaction is completed, the catalyst is obtained by filtration, and the solvent, methanol and epoxy soybean oil-based polyol are obtained by distillation under reduced pressure. The catalyst obtained by filtration and the solvent and methanol obtained by distillation are directly used for the next time Reaction to achieve recycling. Analytical tests were performed on the product.

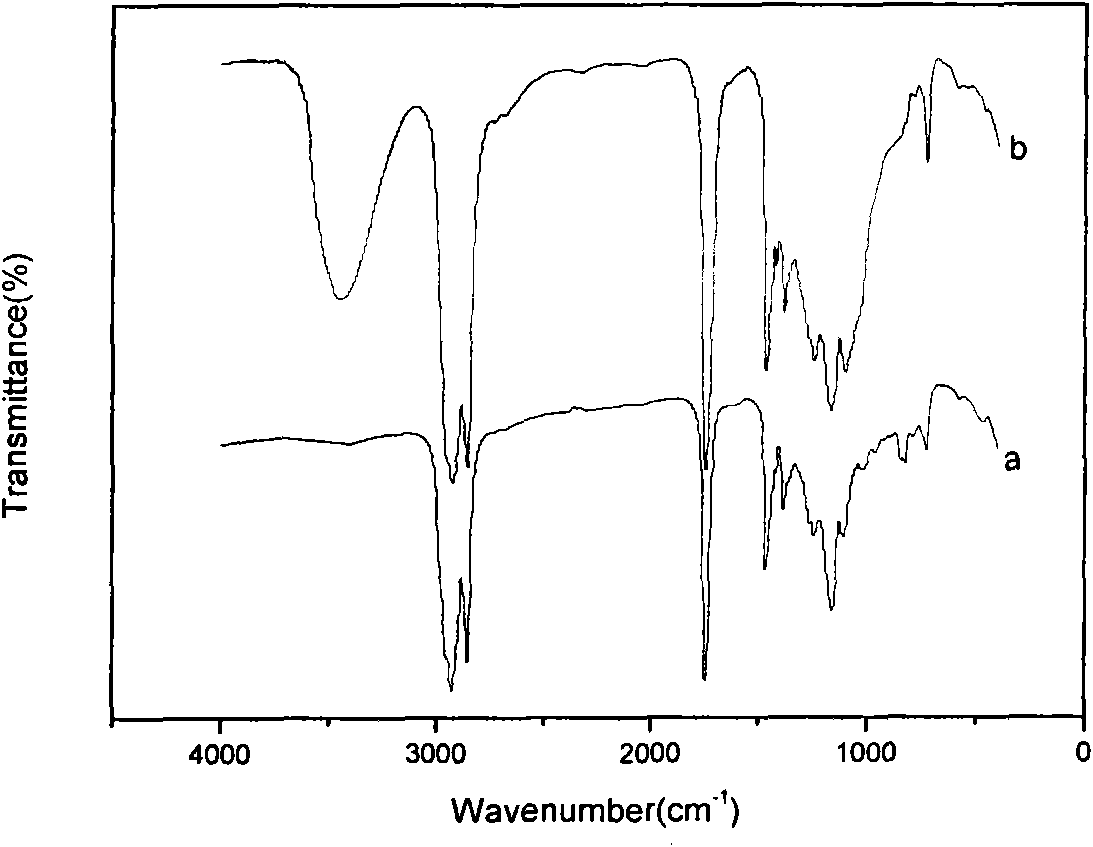

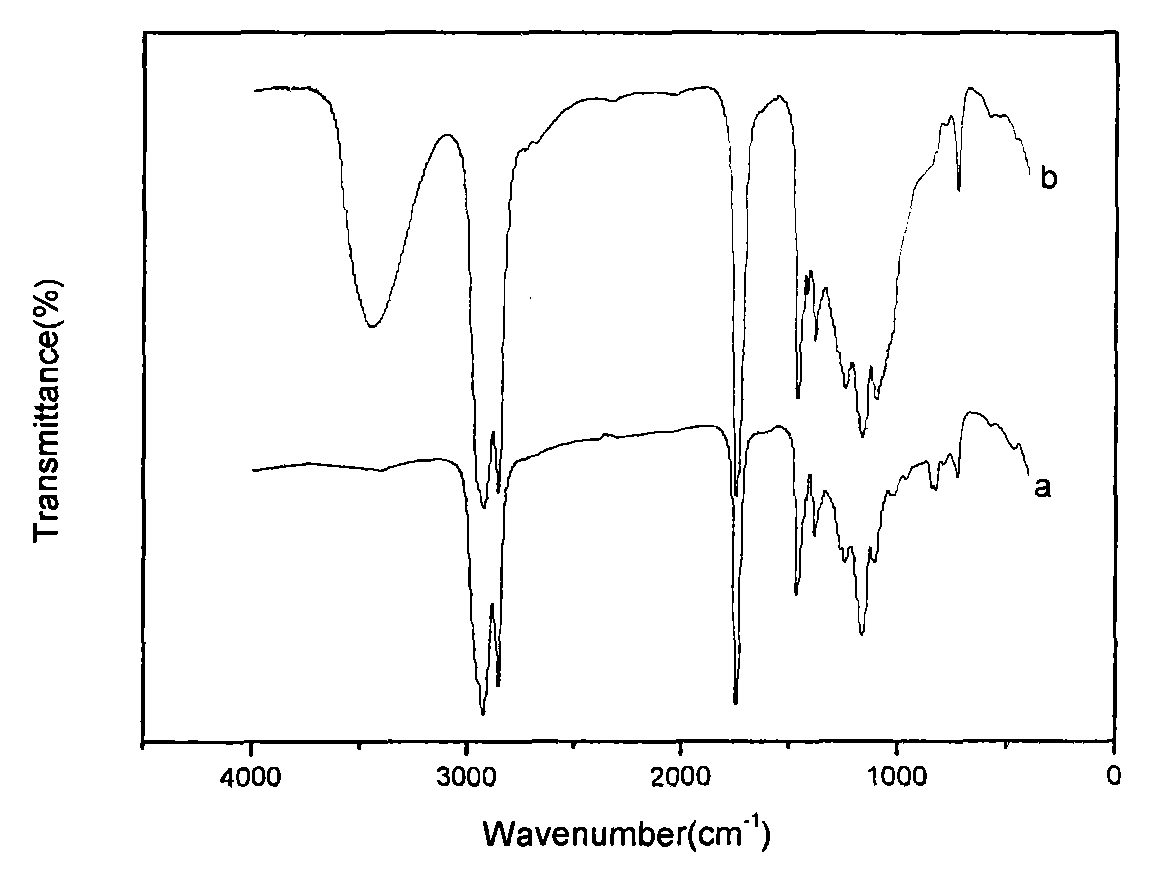

[0025] The epoxy value of the epoxidized soybean oil is 0.376, the epoxy value of the product measured after the reaction is 0.108, and the reaction conversion rate is 71.3%. The reaction products were analyzed by infrared spectroscopy, from figure 1 It can...

Embodiment 2

[0027] In a 100ml autoclave equipped with magnetic stirring, add 20g epoxidized soybean oil, 16g methanol, 4g methyl ethyl ketone, 2g water and 6g NH 4 For ZSM-5, the temperature was raised to 140°C at a heating rate of 5°C / min, and the material was discharged after 20 hours of reaction to obtain an orange-yellow liquid, which was analyzed and tested. The epoxy value of the epoxidized soybean oil is 0.376, the epoxy value of the product measured after the reaction is 0.124, and the reaction conversion rate is 67.0%. All the other are with embodiment 1.

Embodiment 3

[0029] In a high-pressure reactor equipped with magnetic stirring and a volume of 100ml, add 20g of epoxidized soybean oil, 10g of methanol, 4g of acetone, 3g of water and 4g of HZSM-5, and raise the temperature to 160°C at a heating rate of 5°C / min. After reacting for 20 hours, the material was discharged to obtain an orange-yellow liquid, and the product was analyzed and tested. The epoxy value of the epoxidized soybean oil is 0.376, the epoxy value of the product measured after the reaction is 0.006, and the reaction conversion rate is 98.4%. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com