Preparation method of high-purity nano zirconium dioxide

A nano-zirconium dioxide and zirconium dioxide technology, applied in the direction of zirconia, nano-structure manufacturing, nano-technology, etc., can solve the problems of difficult industrial production, expensive production equipment, harsh process conditions, etc., and achieve easy control and dry processing capacity Larger, less reaction time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

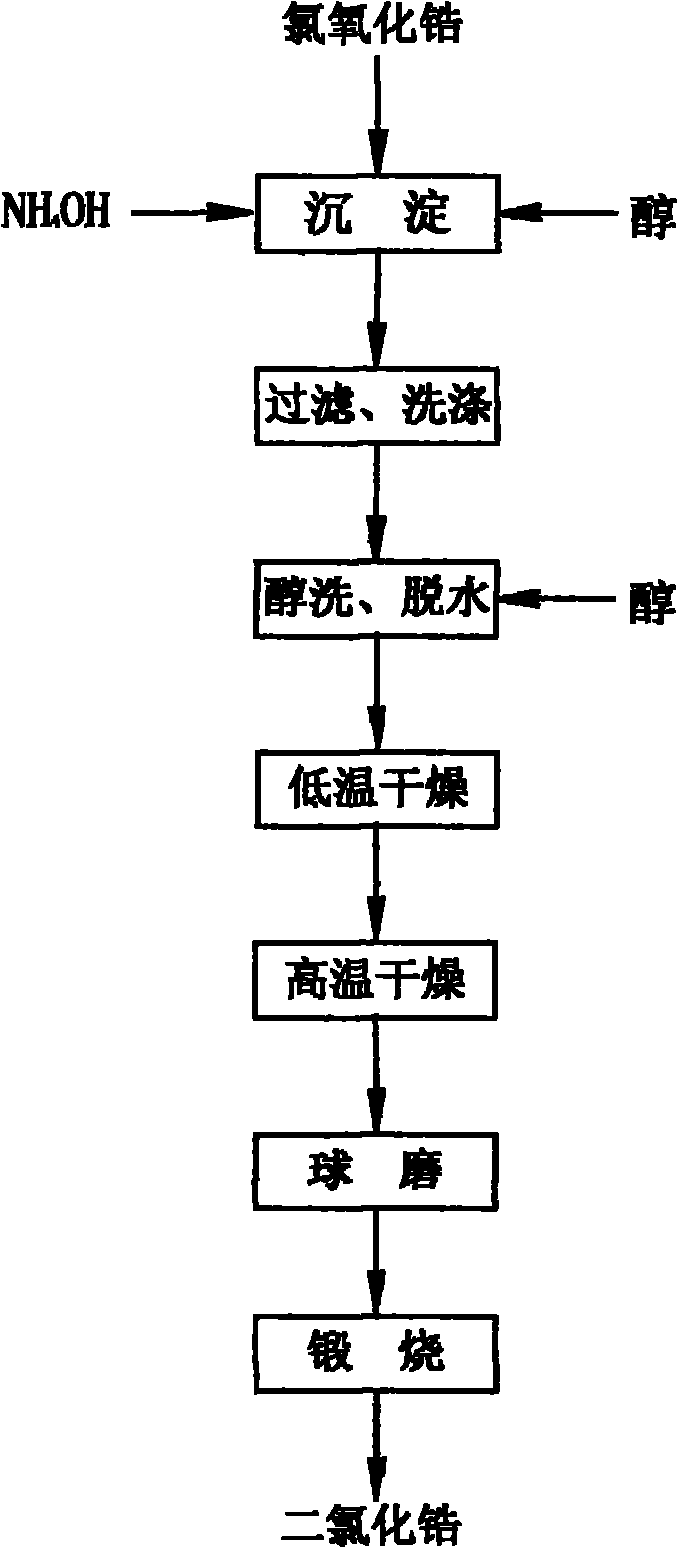

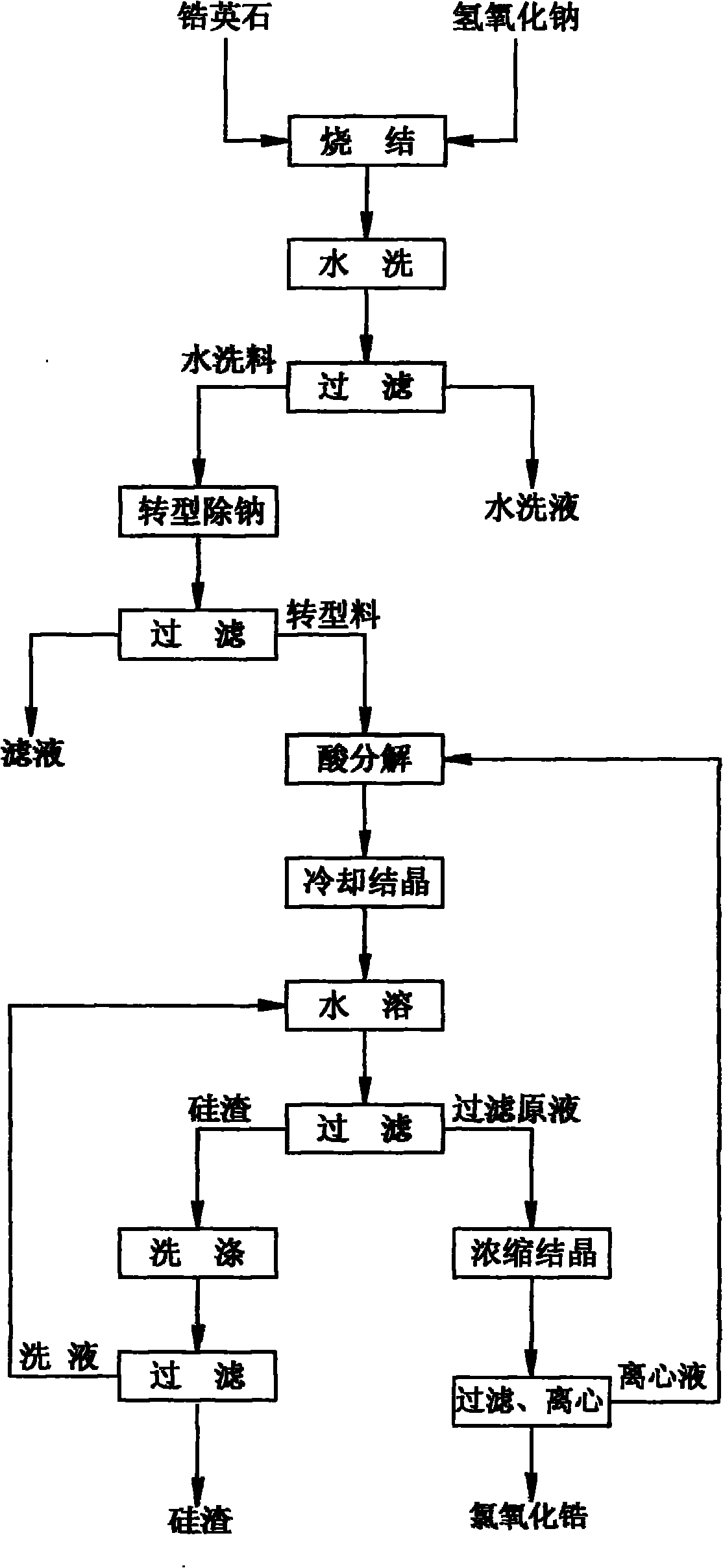

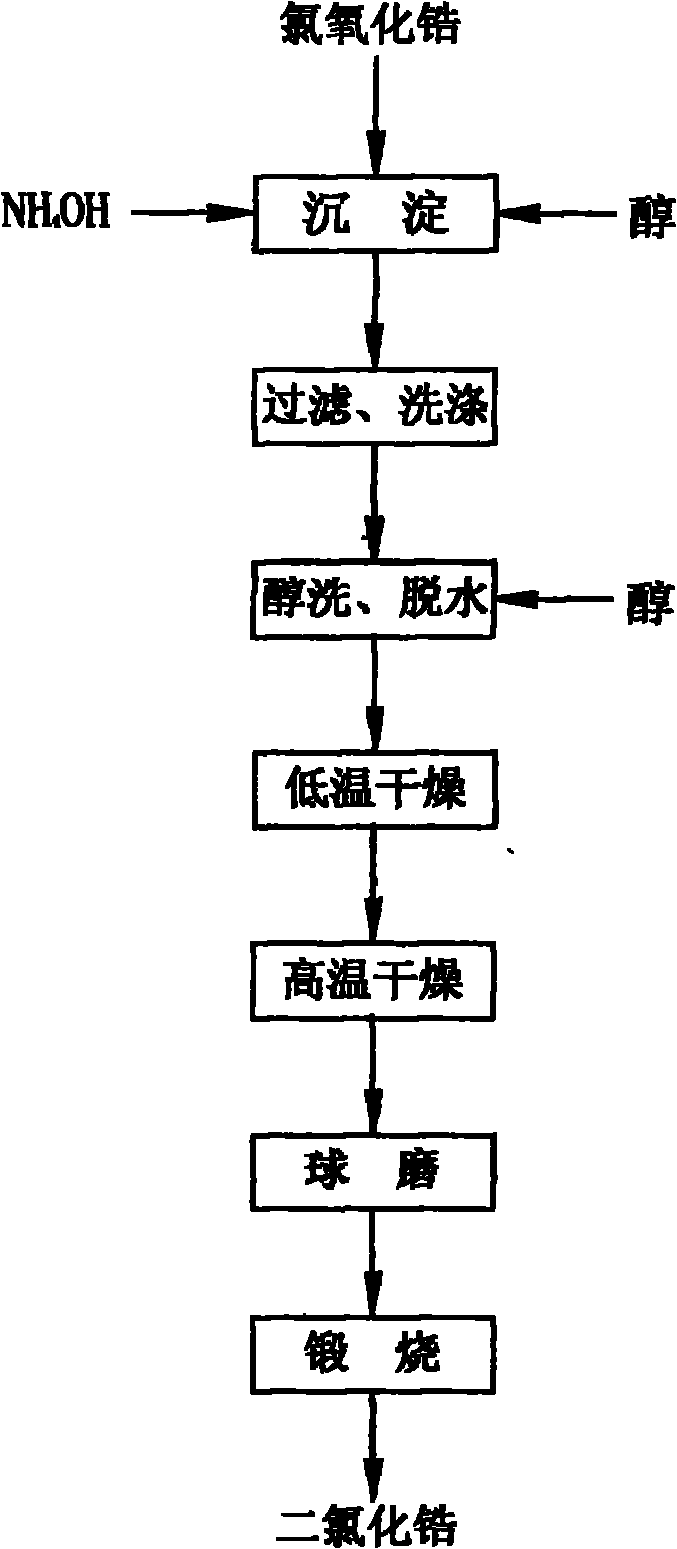

[0025] Such as figure 1 with figure 2 Shown, the preparation method of high-purity nano zirconium dioxide comprises:

[0026] 1. The preparation of zirconium oxychloride comprises steps:

[0027] Sintering, heating sodium hydroxide flake alkali with a content of 99wt% to 750°C in a sintering pot, adding 80-mesh zircon into the sodium hydroxide solution at a mass ratio of 1:1.3, and cooling the sintering after the materials have completely reacted material, after the reaction, the Si conversion rate is greater than 99.5%;

[0028] Washing with water, the sintered material and water are washed according to the mass ratio of 1:8, three-stage reverse water washing is adopted, the temperature of the washing liquid is 80°C, and the washing is for 1.5 hours, and the washing liquid of each washing is removed by a strong magnetic separator to remove iron and other impurities. It is then used for the next level of washing, the removal of silicon can reach 99wt%, the removal rate of ...

Embodiment 2

[0042] Such as figure 1 with figure 2 Shown, the preparation method of high-purity nano zirconium dioxide comprises:

[0043] 1. The preparation of zirconium oxychloride comprises steps:

[0044] For sintering, heat sodium hydroxide flake alkali with a content of 99wt% to 700°C in a sintering pot, add 80-mesh zircon into the sodium hydroxide solution at a mass ratio of 1:1.5, and cool the materials to obtain sintering after the reaction is complete. material, after the reaction, the Si conversion rate is greater than 99.5%;

[0045] Water washing, the sintered material and water are washed according to the mass ratio of 1:7, three-stage reverse water washing is adopted, the temperature of the washing liquid is 90°C, and the washing is performed for 1 hour, and the washing liquid of each washing is removed by a strong magnetic separator to remove iron and other impurities. It is then used for the next level of washing, the removal of silicon can reach 99wt%, the removal rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com