Lactalbumin hydrolysate and application thereof in preparing glucose-lowering medicament

A technology of whey protein hydrolysis and whey protein, which is applied in the field of preparation of hypoglycemic drugs, can solve problems affecting product quality and biological safety, achieve good application prospects and market prospects, reduce glucose tolerance, and increase insulin content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

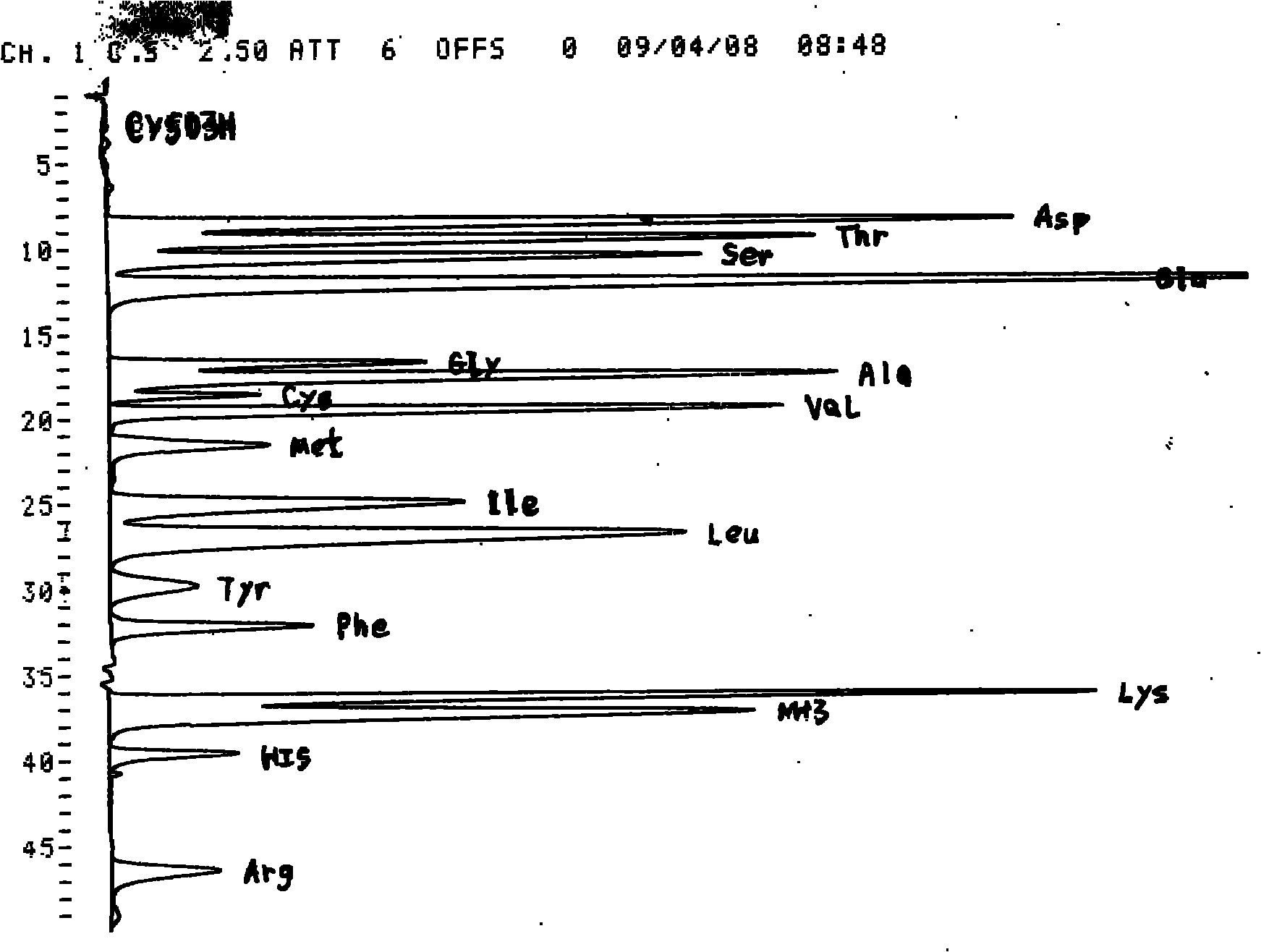

Image

Examples

Embodiment 1

[0042] Example 1 Preparation and purification of whey protein hydrolyzate

[0043] 1. Take 50g of whey protein sample, dissolve it in 1000ml of 40°C distilled water, heat to 85°C, and hydrate for 15 minutes. At this stage, the color of the solution changes from light yellow to milky white, and has a milky aroma.

[0044] 2. Cool down to 55°C and adjust the pH to 8.0 with 1N NaOH.

[0045] 3. Maintain the temperature at 55°C, quickly add 3g of alkaline protease (6%, W / W), and constantly adjust the pH value to 8.0 with 1N NaOH during the hydrolysis process until the pH does not change anymore. The average alkali consumption is 90ml / 50g sample, the reaction time is about 5~6h.

[0046] 4. Heat to 90°C for 15 minutes to inactivate alkaline protease.

[0047] 5. Cool to normal temperature and measure the salt content.

[0048] 6. Use a low-temperature high-speed centrifuge at 4°C, 3000rpm, for 20min, and take the supernatant.

[0049] 7. Put the hydrolyzate into a Model 8400 u...

Embodiment 2

[0051] Example 2 Determination of the Nitrogen Content and Recovery of the Whey Protein Hydrolyzate Prepared in Example 1

[0052] 1. Bake each part of the product in the process of hydrolysis and purification in an oven at 80°C until the weight is constant.

[0053] 2. Use the Kjeldahl method to detect the nitrogen content and calculate the recovery rate according to the weighing table, the results are shown in Table 1.

[0054] Table 1

[0055]

[0056] It can be seen from Table 1 that the nitrogen content of the whey protein hydrolyzate prepared in Example 1 of the present invention is 67.9% as detected by the Kjeldahl method, and the recovery rate is 102.5%.

Embodiment 3

[0057] Example 3 Determination of alkali consumption and degree of hydrolysis of the whey protein hydrolyzate prepared in Example 1 (formaldehyde method)

[0058] 1. Neutralization of formaldehyde: Formaldehyde solution will be partially oxidized to formic acid after long-term storage. Before use, take the original formaldehyde upper layer solution and add distilled water to dilute it twice, then titrate with 0.1mol / L NaOH standard solution to pH 7.0 for later use.

[0059] 2. Take 8 ml of the protein hydrolyzate prepared in Example 1 and add 60 ml of double-distilled water, magnetically stir and titrate to pH 7.0 with 0.05mol / L NaOH under the indication of a precision pH meter, add 10 ml of neutralized formaldehyde solution, and record The volume V1 (ml) of the 0.1mol / L NaOH solution consumed when its pH is titrated to 9.2, take 8ml of the unhydrolyzed protein solution of the same concentration at the same time, do a blank experiment according to the above steps, and record th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com