Taxol nanoparticle composition and preparation method thereof

A nanoparticle and paclitaxel technology, which is applied in drug combinations, pharmaceutical formulas, and medical preparations containing active ingredients, can solve problems such as high cost, drug residues, and increased drug toxicity, and achieve high drug loading and good mucosal tissue High adhesion and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

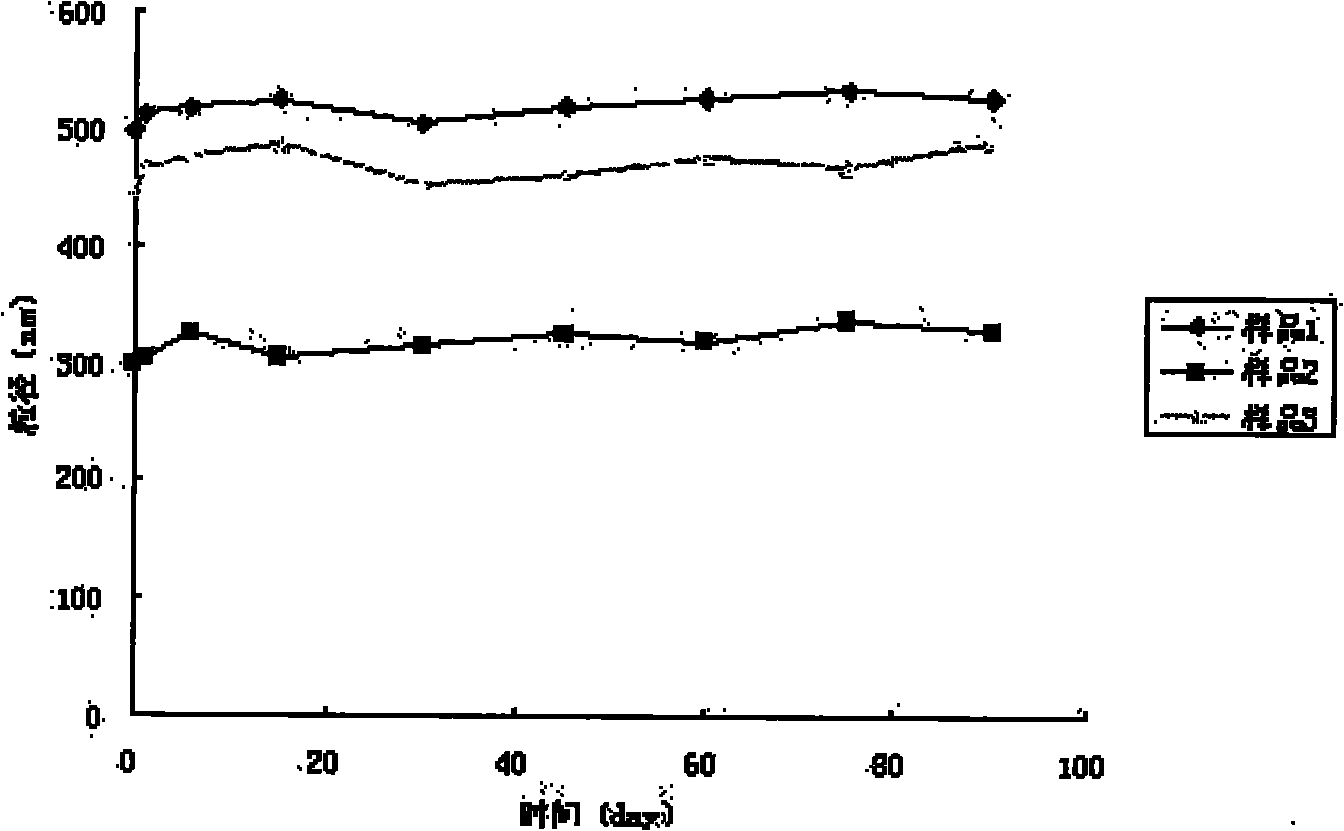

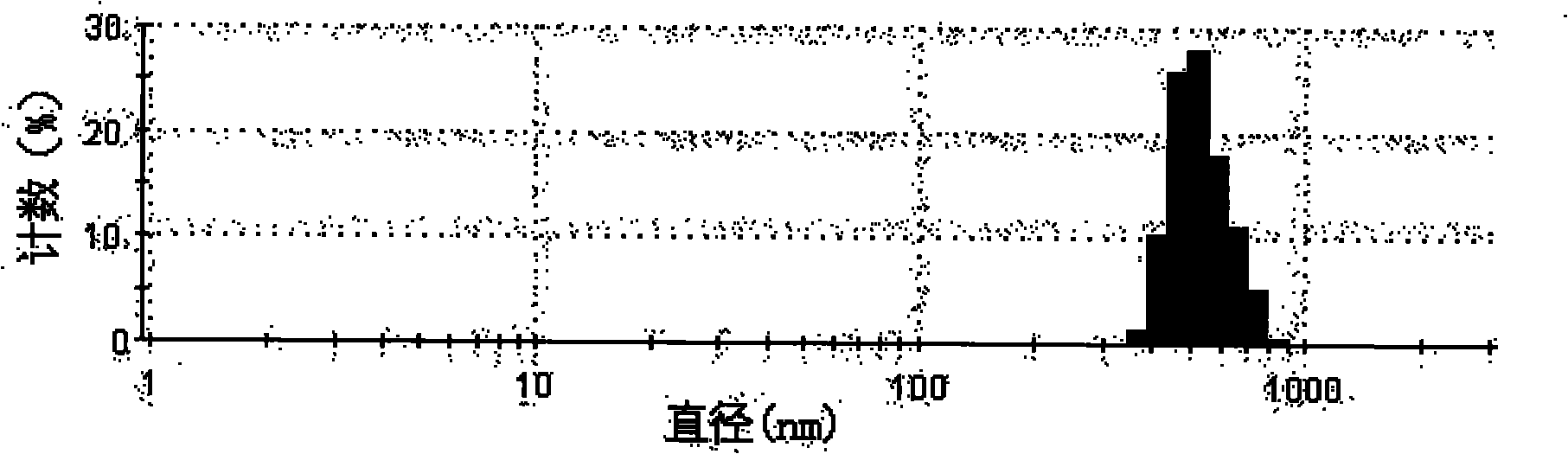

[0081] The purpose of this example is to prepare paclitaxel nanoparticle composition injections with various surface stabilizers.

[0082] Mix 2 g of Paclitaxel with 1.25 g of at least one of the following surface stabilizers: Taboxamer, Poloxamer 188, Tween-80, Hydroxypropylmethylcellulose, Hydroxypropylcellulose, Polyvinylpyrrolidone-K30 , Sodium Lauryl Sulfate, Macrogol 400, Sodium Deoxycholate, Lecithin.

[0083] For each combination of paclitaxel and surface stabilizer, first dissolve 1.25g of surface stabilizer in 96.75g of water for injection, then add 2g of paclitaxel, ultrasonically disperse evenly, add 50mL of zirconium beads in a ball mill, and circulate condensation at 1500rpm The water temperature was controlled at 4°C, and the mixed solution of paclitaxel and surface stabilizer was added while stirring. After degassing for 10 minutes, the speed was increased to 4000 rpm, and the wet grinding was carried out for a total of 30 minutes to obtain a milky white paclit...

Embodiment 2

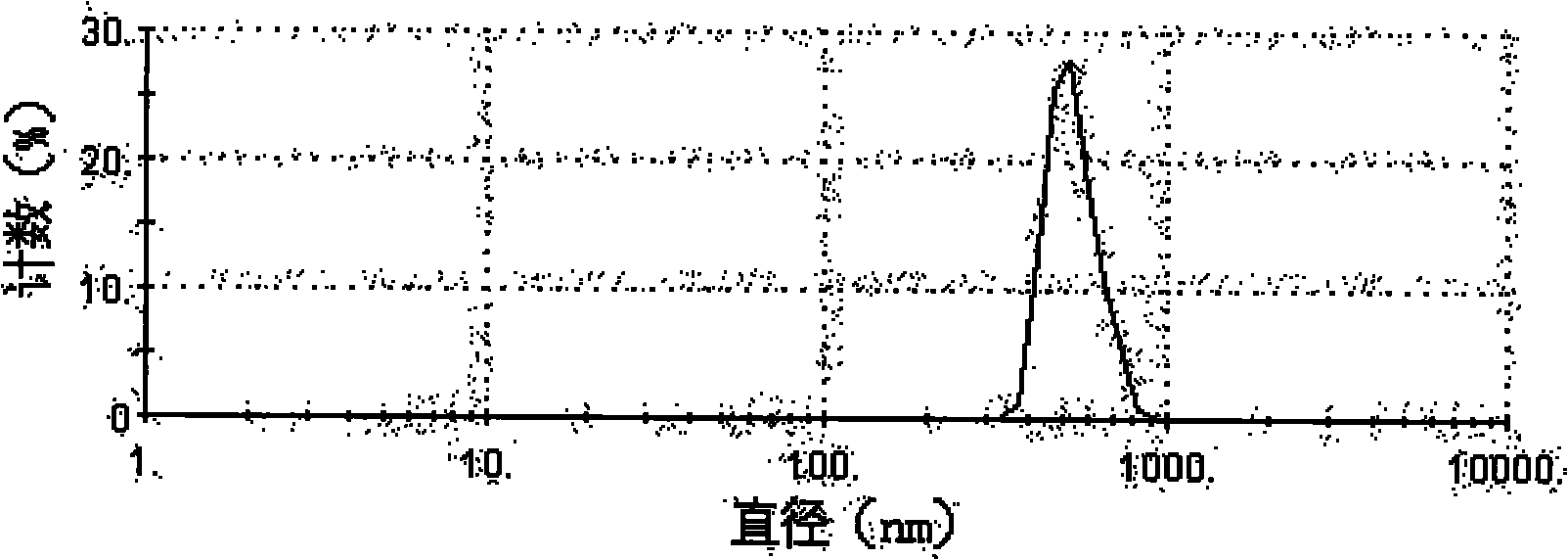

[0093] The purpose of this example is to prepare paclitaxel nanoparticle composition oral formulations with various surface stabilizers

[0094] Dissolve 2 g of hydroxymethylpropyl cellulose and 1 g of poloxamer 188 in 92 g of water for injection to prepare a solution, then add 5 g of paclitaxel, and disperse the above mixture solution evenly by ultrasonic, add 50 mL of zirconium beads in a ball mill, and start at 1500 rpm Under the rotating speed, the temperature of the circulating condensed water is controlled at 4°C, and the mixed solution of paclitaxel and surface stabilizer is added while stirring. After degassing for 10 minutes, the rotating speed is increased to 4000rpm, and the wet grinding is carried out for 30 minutes to obtain a milky white paclitaxel suspension, which is then freeze-dried at low temperature to obtain White solid granules, pass through 80 mesh sieve, mix the obtained granules with appropriate amount of starch, add appropriate amount of starch slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com