Bioactive facial mask and preparation method therefore

A bioactive and bioactive factor technology, applied in the field of daily cosmetics, can solve the problems of destroying the natural silk fibroin structure, losing the biological efficacy of silk fibroin, and not having bioactive functions, etc., achieving process maturity and accelerating skin tissue repair. , the effect of good biosafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: be used for the bioactive mask of face liposuction water-retaining nutrition

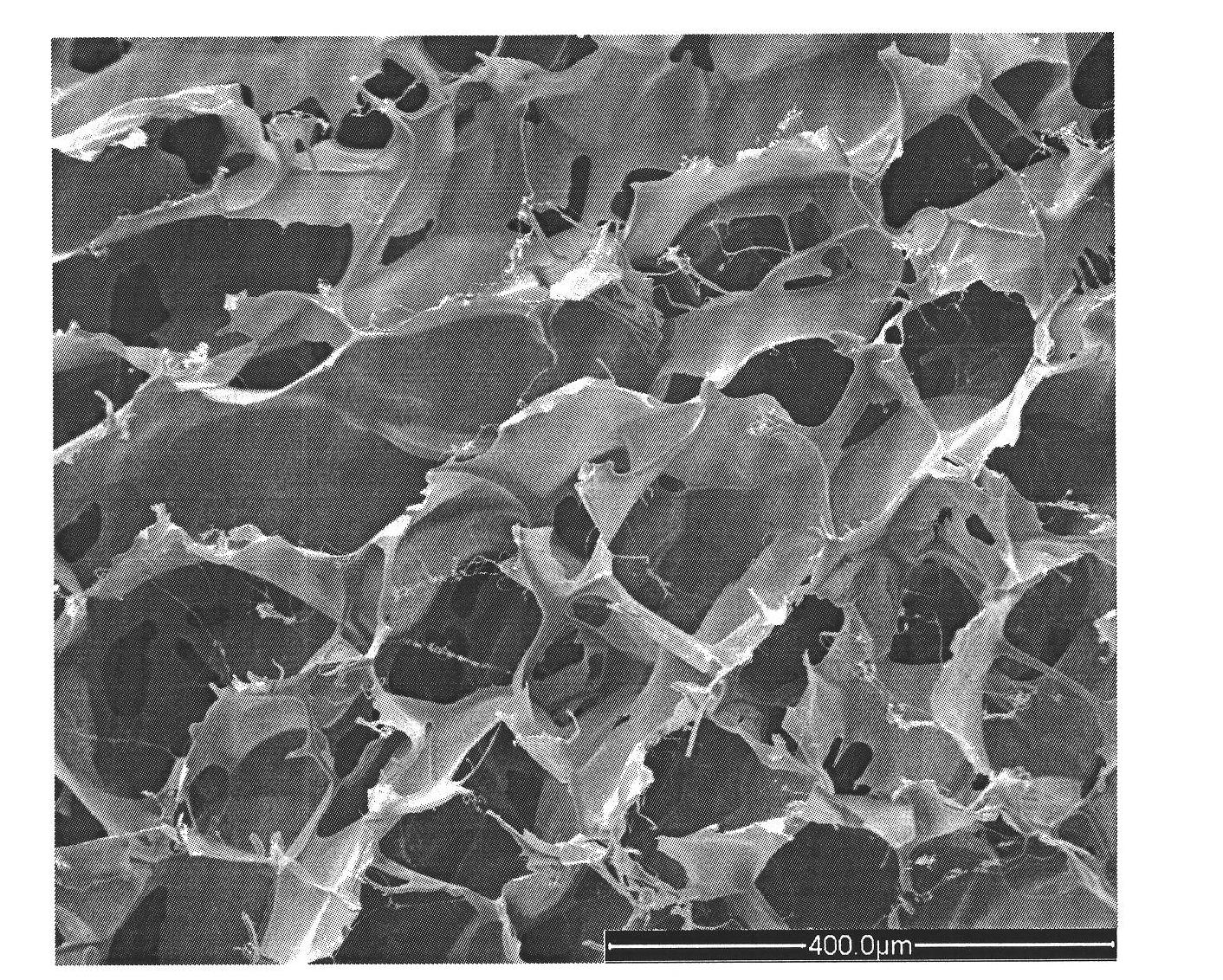

[0024] Weigh 8g of silk fibroin with a balance, add it to 20ml of sterilized water, stir and dissolve for 1 hour, and after degassing for 1 hour, pour it into a mold and cast it to form a film. In this example, a plastic mold is used, and it is volatilized at room temperature. After 2 days, vacuum-dry at 60° C. for 12 hours to obtain a scaffold layer. Separately take silk fibroin and dissolve it in deionized water to form a silk fibroin aqueous solution with a concentration of 30wt%, and then apply it evenly on the surface of the above-mentioned support layer to form a silk fibroin water layer with a thickness of 2 mm, and quickly put it Freeze in a -80°C refrigerator for 10 hours to fix the silk fibroin aqueous layer on the support layer, and then put it into a vacuum freeze dryer to dry at -60°C for 10 hours to obtain a porous nano active layer. Add natural plant extract (suc...

Embodiment 2

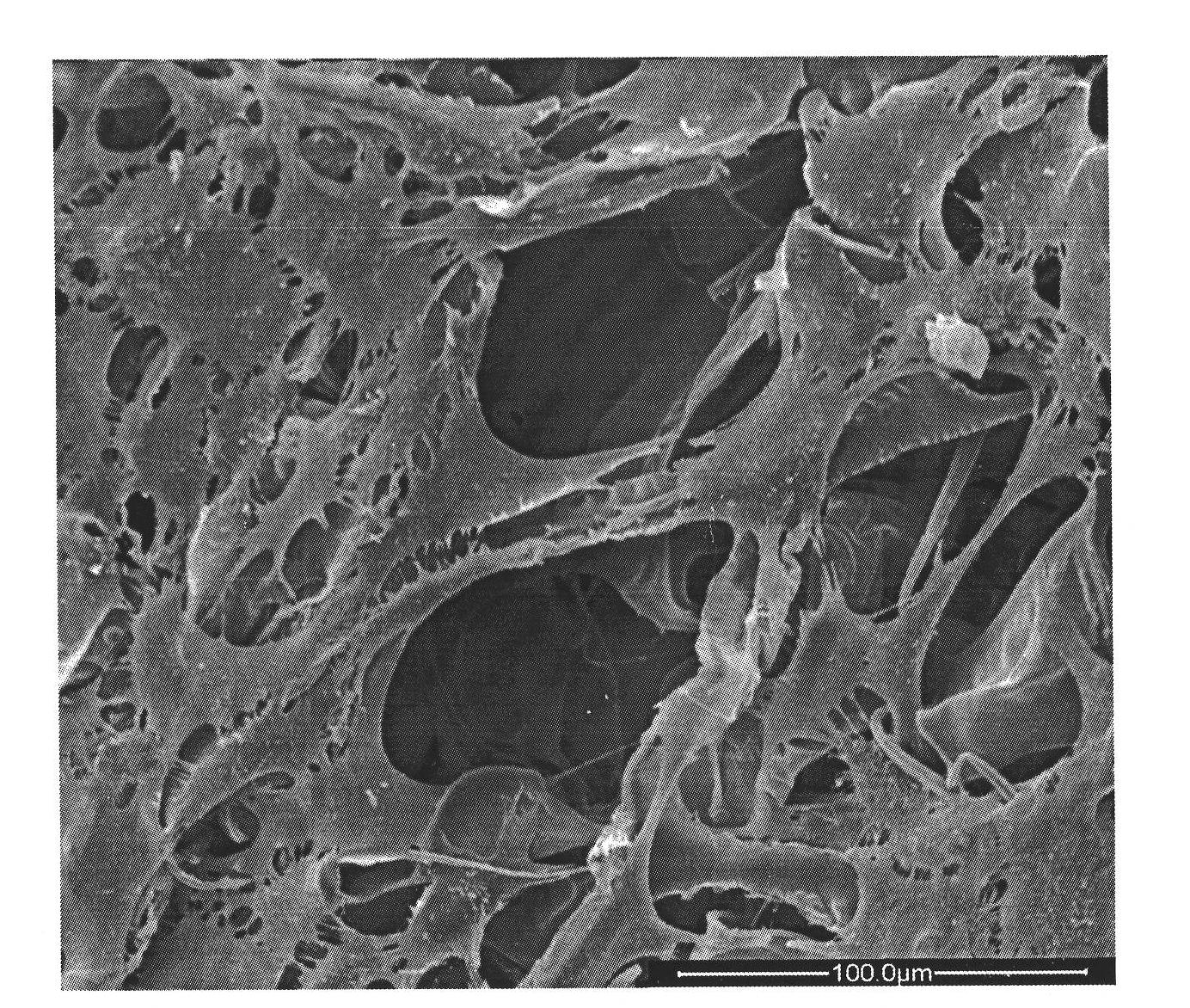

[0025] Example 2: Bioactive Mask for Facial Skin Tissue Regeneration

[0026] Weigh 8g of silk fibroin with a balance, add it to 20ml of sterilized water, stir and dissolve for 1 hour, and after degassing for 1 hour, pour it into a mold and cast it to form a film. In this example, a plastic mold is used, and it is volatilized at room temperature. After 2 days, vacuum-dry at 60° C. for 12 hours to obtain a scaffold layer. Adopt electrospinning method, carry out spray spinning on above-mentioned support layer with the silk fibroin protein aqueous solution of concentration 20wt% according to conventional conditions, obtain the silk fibroin protein aquifer layer that thickness is 3mm, put it into -80 ℃ refrigerator to freeze rapidly 5 hours, the silk fibroin aqueous layer was fixed on the support layer, and then placed in a vacuum freeze dryer at -30° C. for 15 hours to obtain a porous nano active layer. The epidermal growth factor is added to the silk fibroin aqueous solution wi...

Embodiment 3

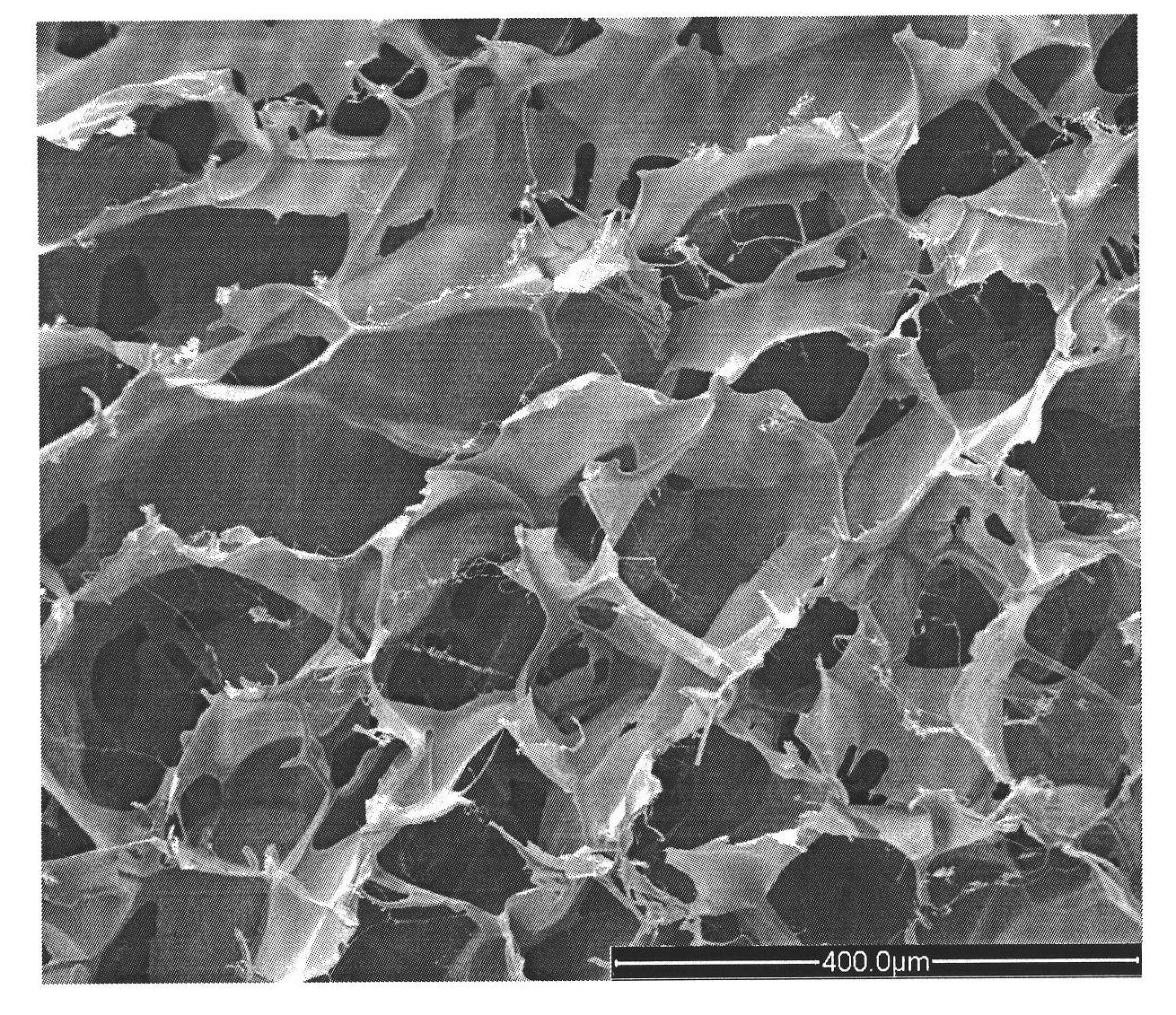

[0027] Example 3: Bioactive Mask for Facial Skin Repair

[0028] Weigh 8g of silk fibroin with a balance, add it to 20ml of sterilized water, stir and dissolve for 1 hour, and after degassing for 1 hour, pour it into a mold and cast it to form a film. In this example, a plastic mold is used, and it is volatilized at room temperature. After 2 days, vacuum-dry at 60° C. for 12 hours to obtain a scaffold layer. Using the electrospinning method, according to the conventional conditions, the silk fibroin aqueous solution with a concentration of 25wt% is sprayed on the above-mentioned support layer to obtain a silk fibroin water layer with a thickness of 5 mm, which is quickly put into a -80 ° C refrigerator for 7 hours. The silk fibroin aqueous layer is fixed on the support layer, and then placed in a vacuum freeze dryer for drying at -60° C. for 10 hours to obtain a porous nano active layer. The epidermal cell repair factor is added to the silk fibroin aqueous solution with a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com