Coal mining process of drilling, loading, conveying and anchoring integral machine

A process and mechanical technology, applied in the field of underground recovery and recovery, to achieve the effect of less investment in equipment, advanced support means, and increase the rate of resource recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

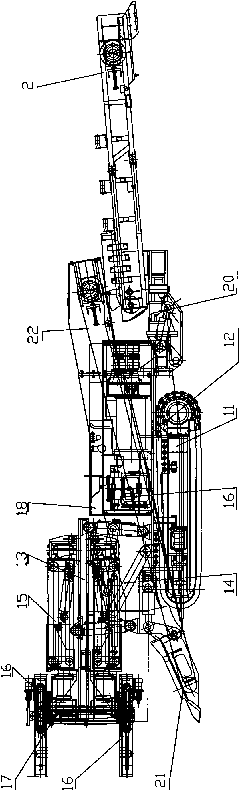

[0050] Describe in detail below in conjunction with accompanying drawing:

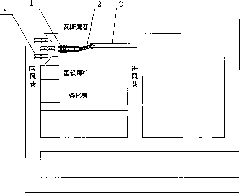

[0051] Such as figure 1 As shown, the coal mining process equipment layout of the strip-shaped house drilling, shipping and anchoring integrated machine of the present invention is shown. Roadway layout: Divide several sections in the panel area, and arrange two preparation roadways in the section, of which: one is used as the air inlet lane, and the other is used as the return air lane. After mining in the previous section, the air inlet lane can be used as the air return lane in the next section, and only one air inlet lane needs to be excavated in the next section. In the middle of the two preparation roadways, a long strip-shaped pillar is arranged. The long strip-shaped pillar is about 16m wide and 20-150m long. The design layout is 5m wide and 5+4=9m wide. When mining the next room pillar, it is carried out under a small roof pressure. The panel preparation roadway is determined according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com