Thermo-sensitive material and sprinkler head for using same

A heat-sensitive material and sprinkler technology, used in fire rescue and other directions, can solve problems such as unreasonable design, groundwater pollution, and appearance deterioration, and achieve good creep characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

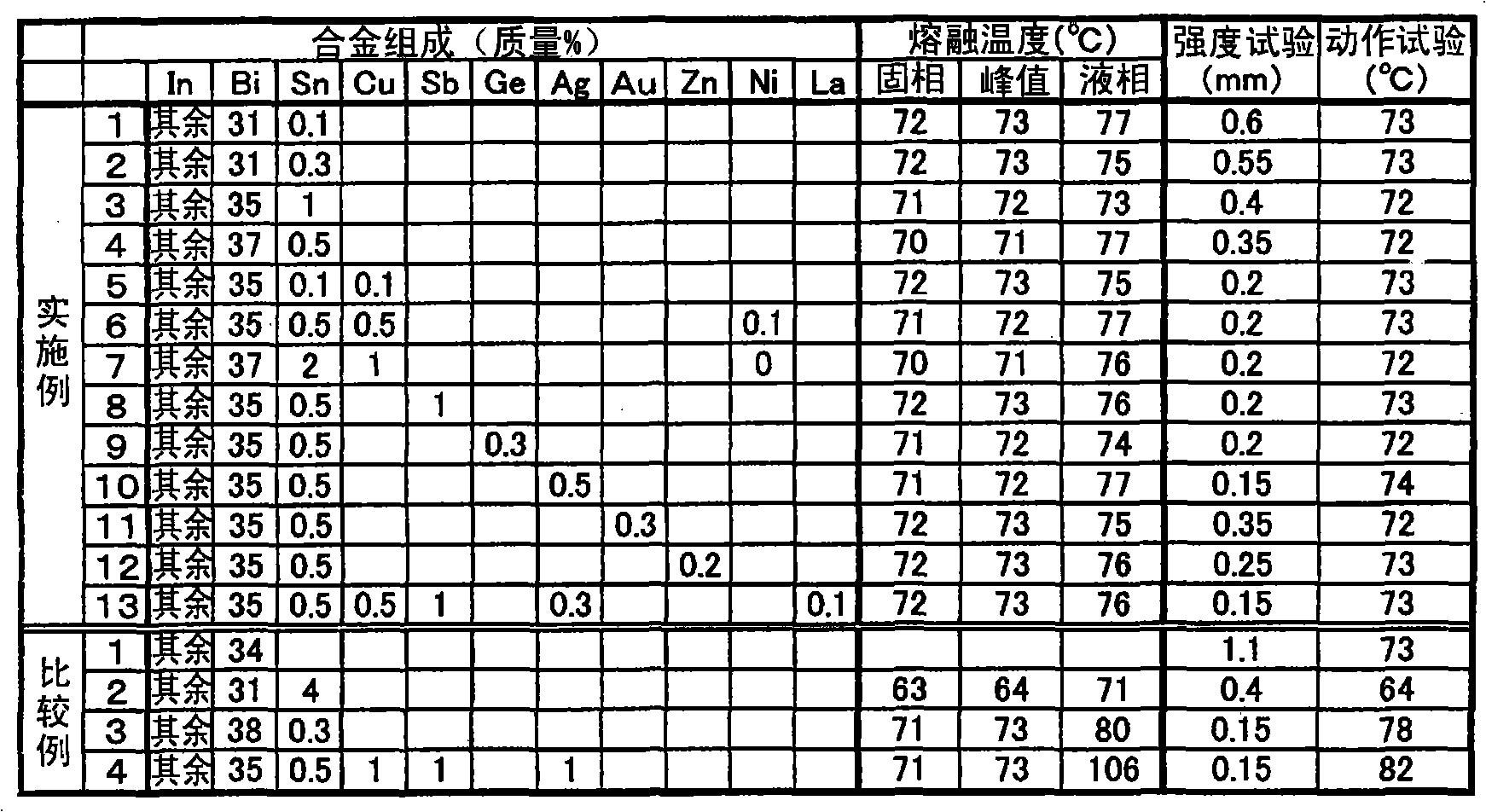

[0035] An alloy for a heat-sensitive material of a thermally decomposed part of the sprinkler head of the present invention and a sprinkler head are produced.

[0036] Alloys for heat-sensitive materials for the heat-sensitive decomposition part of the sprinkler head described in Table 1 and Table 2 were produced, and the heating curve was measured for each alloy composition by differential thermal analysis, using the start point of the endothermic peak and the lowest point of the endothermic peak , The end point of the endothermic peak, and measure the solid phase temperature, peak temperature, and liquid phase temperature. Table 1 and Table 2 show the melting temperature of each alloy.

[0037] Comparative Example 1 in Tables 1 and 2 is an alloy for a heat-sensitive material in the thermally decomposed part of the sprinkler head of Patent Document 1.

[0038] The measurement conditions of the melting temperature are as follows.

[0039] 1. Determination of differential the...

Embodiment 2

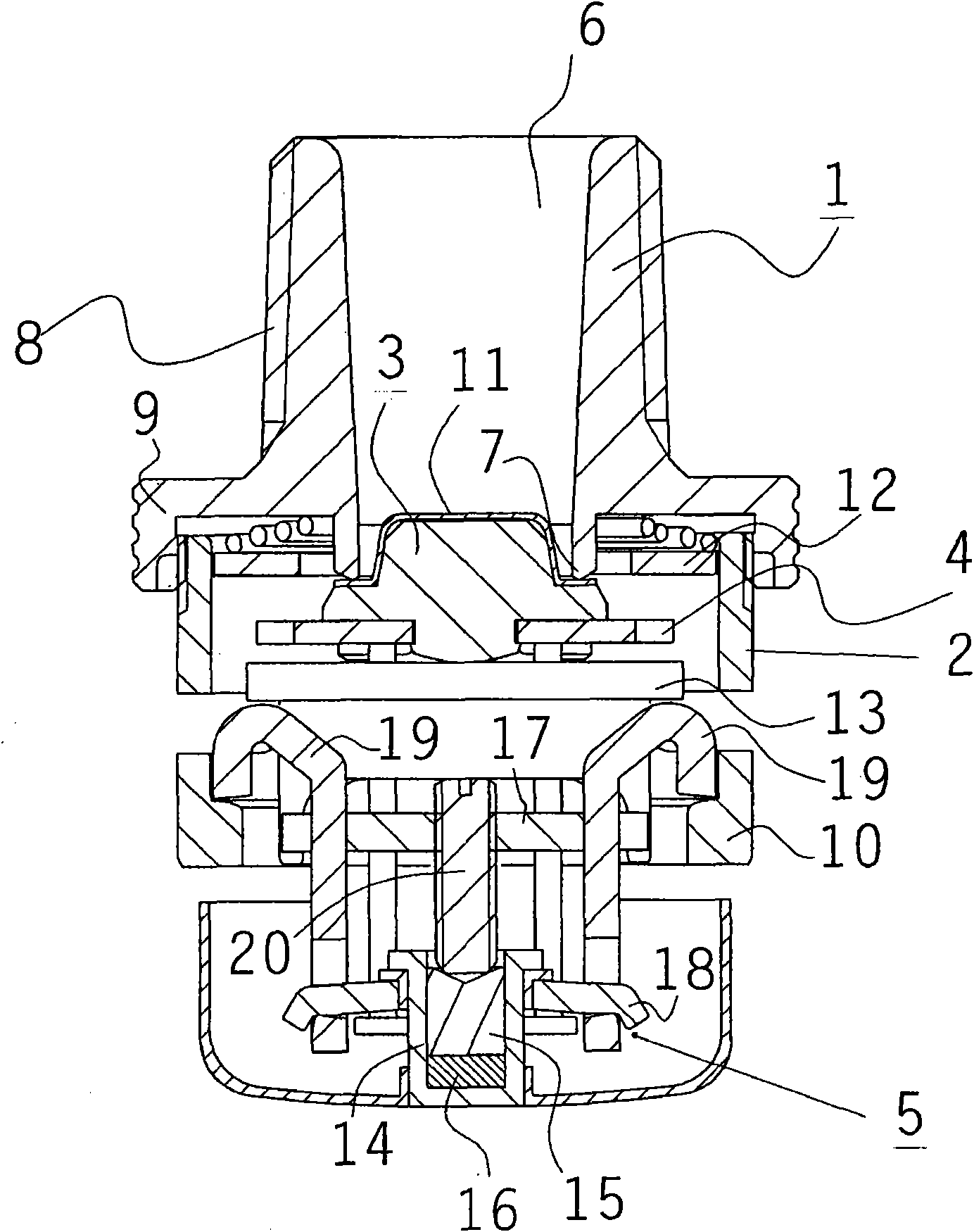

[0048] Here, a sprinkler head incorporating a compression-type thermal decomposition part will be briefly described. figure 1 It is a front cross-sectional view of a sprinkler head incorporating a compression-type thermal decomposition part.

[0049] The sprinkler head S is composed of a body 1 , a frame 2 , a valve body 3 , a deflector 4 , and a heat-sensitive decomposition part 5 .

[0050] The main body 1 is provided with a water guide hole 6 through its center, and its lower end is a valve seat 7 . In addition, an external thread 8 is screwed on the upper part of the outer periphery of the body 1 , and a flange 9 is formed at the lower end thereof.

[0051] The frame 2 is cylindrical, its lower end is an inner flange 10 , and its upper end is screwed with the above-mentioned flange 9 .

[0052] The upper part of the valve body 3 is covered with a gasket 11, and the valve seat 7 of the body 1 is usually sealed in a watertight state.

[0053] The deflector 4 is disc-shape...

Embodiment 3

[0058] below, in figure 1 In the sprinkler head shown, the creep characteristics (referred to as a strength test) and the operating temperature of the thermally decomposed part were measured for each alloy composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com