Auxiliary cold extrusion machining device with large diameter and inner thread based on electromagnetic vibration exciter

An electromagnetic exciter and auxiliary processing technology, applied to threaded products, other household appliances, household appliances, etc., can solve the problems of easy breakage of taps, unsatisfactory thread surface integrity, difficult flow of coolant, etc., to achieve improved The effect of processing quality, low surface roughness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

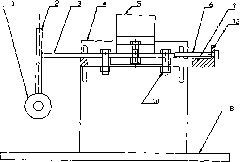

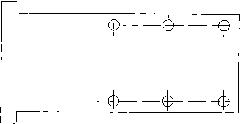

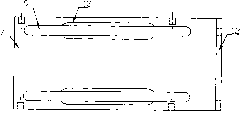

[0026] Such as Figure 1-5 shown.

[0027] An auxiliary processing device for large-diameter internal thread cold extrusion based on an electromagnetic exciter, which is mainly composed of a base 4, a fixed plate 7, a torsional vibration plate 3 and an electromagnetic exciter 5, and the fixed plate 7 is installed on the base 4. The height position is adjustable, and the base 4 is fixedly installed on the slide plate 8 of the machine tool. For the convenience of adjustment, the base 4 can adopt a U-shaped structure, and the torsional vibration plate 3 is installed on the fixed plate 7. The torsional vibration rod 2 is offset, and the other end is offset with the adjustment screw 6 on the flange 12 on the end of the fixed plate 7. The extrusion tap fixture 1 and the torsional vibration rod 2 installed on it are the same as the prior art or can be used E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com