Permanent magnet opening gradient sorting device

A sorting device and permanent magnet technology, applied in the direction of high-gradient magnetic separator, etc., to achieve the effect of satisfying uniformity and dispersion, solving particle inclusion, and avoiding non-selective adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

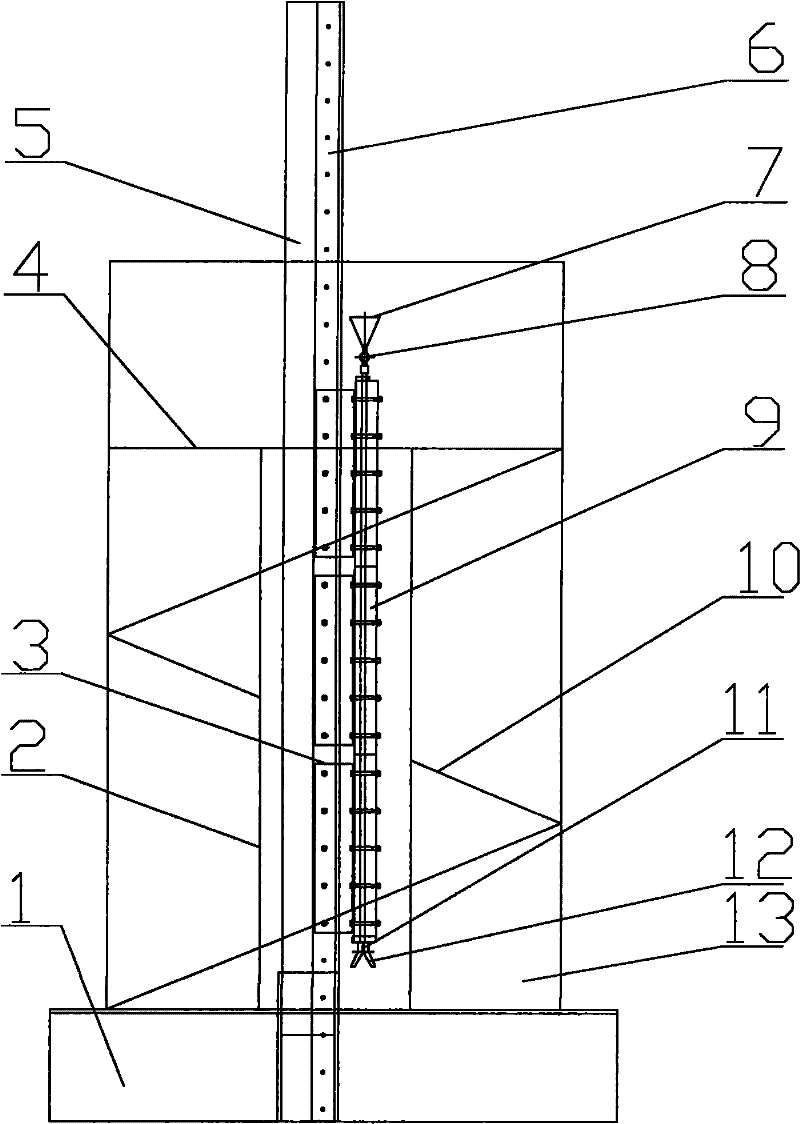

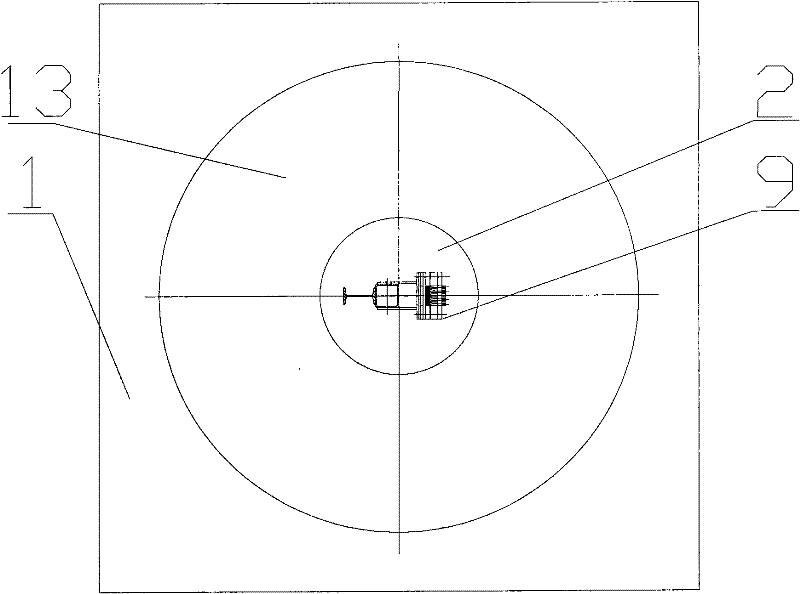

[0045] Such as figure 1 , 2 As shown, the present invention is structurally mainly composed of a magnetic separation column 9, a closed-air variable feeder 7 and a vibrating homogenizer 8, a series two-stage continuous vibrating feeding system, a closed-air separation partition 11, and a discharge bin. 12. The maintenance window 2, the easy-to-operate rotating ladder 10 and the operating platform 4, as well as the machine base 1 and the tower body 13 constitute.

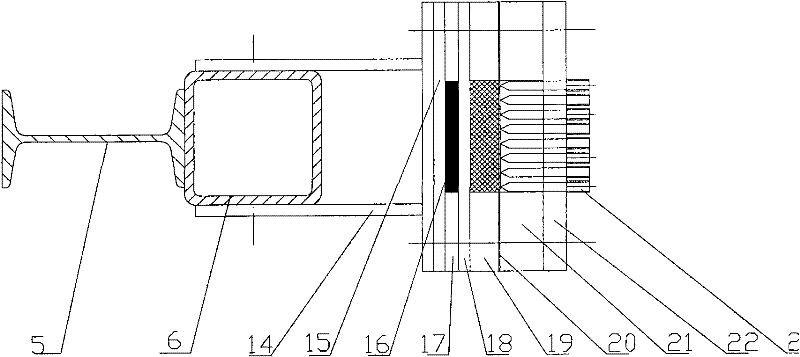

[0046] Such as image 3 , 4 Shown, the permanent magnet open gradient separation device of the present invention comprises the magnetic separation column 9 that is installed on the upright post that is installed on the vertical column by connecting piece, is installed in the sorting cavity 19 top feed inlet places of magnetic separation column 9 by vibration The series-connected two-stage continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com