Rotating and twisting device of optical fiber image inverter

A technology of image inverter and braking device, which is applied in the direction of bundle of optical fibers, etc., can solve the problems of difficult product quality assurance, uneven heating of composite wire rods, and falling deviation, so as to avoid uneven heating, easy to operate, and easy to manufacture. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

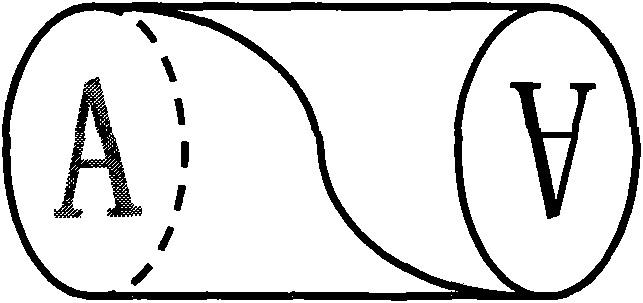

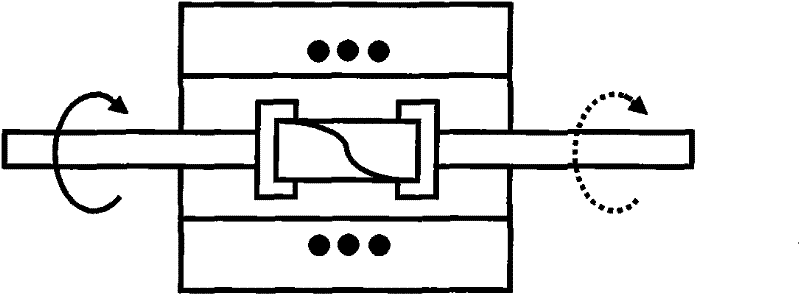

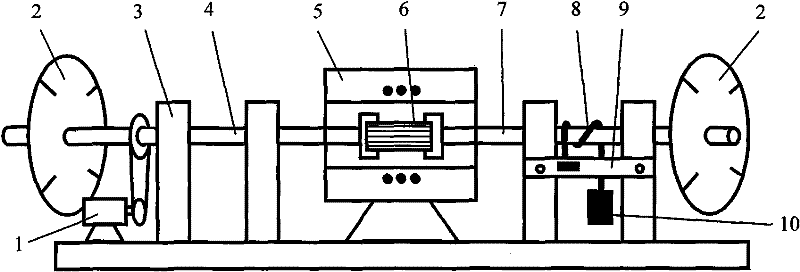

[0014] according to figure 1 The principle of the optical fiber inverter is shown. In order to make the optical fiber inverter, firstly, thousands of optical fiber multifilaments are regularly arranged, melted and pressed into an optical fiber composite wire rod, and then placed on a special device for heating and twisting. Specific device reference image 3 Assembled with the above summary of the invention, wherein the bracket 9 of the braking device is fixed on the double columns of the frame 3, and the motor 1 drives the main shaft 4 to rotate through the belt. Such as figure 2 , image 3 , clamp a Φ20mm×30mm optical fiber composite wire rod 6 between the main shaft 4 and the driven shaft 7 in a horizontal state, then place it in the heating furnace 5, and adjust and record the corresponding starting points of the left and right angle discs 2 scale.

[0015] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com