Bridge cutoff type integrated house and installation method thereof

A technology for integrating houses and broken bridges, which is applied to residential buildings, building components, and thermal insulation. It can solve problems such as the loss of thermal insulation effect of the thermal insulation filling layer, and achieve the goal of improving integrity and safety, ensuring overall strength, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

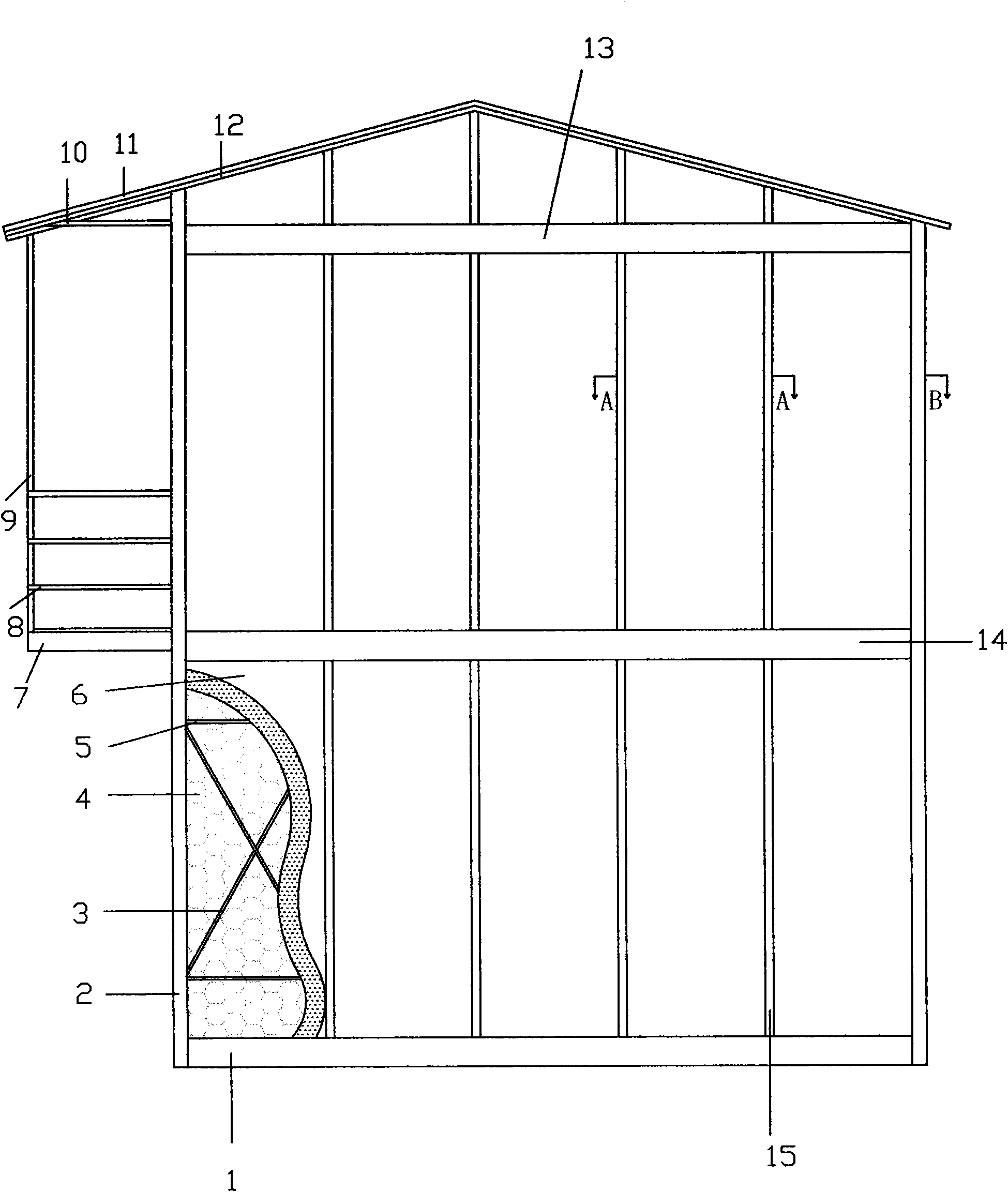

[0020] The present invention takes a two-story integrated building as an example;

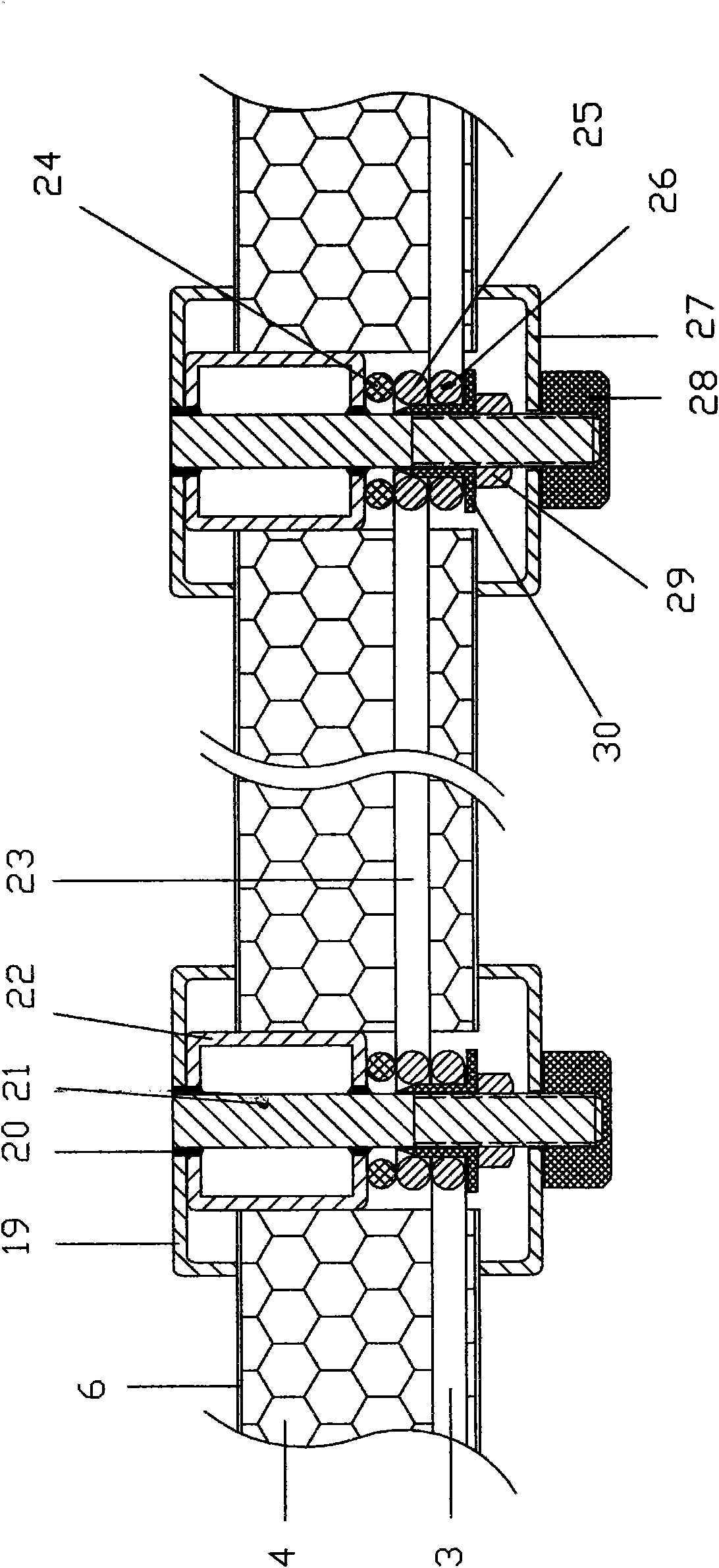

[0021] Depend on Figure 1-5 As shown, 1 in the figure is a ground beam, four right-angled hollow corner columns 2, several square wall columns 22, ring beams 14, four roof beams 13, and several wall panels with metal inner and outer wall panels and thermal insulation filling layers 6. A number of metal floor boards, roof girders 10, cross-tension beams 12 between roof girders 10, roof panels 11, stairs 17 with outdoor corridors, doors and windows, characterized by: A fork-shaped tie bar 3 is arranged in the filling layer 4 , and a connecting ring 25 is arranged at the end of the fork-shaped tie bar 3 , and the connecting ring 25 at the end of the fork-shaped tie bar 3 is arranged outside the side of the wall panel 6 . A strengthening tie bar 5 is also connected to the two fork-shaped tie bars that are correspondingly arranged and close to the connecting ring.

[0022] Such as image 3 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com